KONE Maintenance Method

MX10 / MX20 MCP Procedures - ASME A17.1-2013 / CSA B44-13

© 2014 KONE Corporation PSK8-604-MX10/MX20

All rights reserved.

58 (-) 2014-12-15

3.5 Maintenance Procedures in the Pit

8.6.4.4: Maintenance Procedure for Oil Buffers (if installed)

Procedure Service Intervals

Check the oil level Once a year

Drive the car or counterweight on the buffer and check to ensure

the piston returns to its normal position.

Once a year

Check to ensure the safety switch operates properly. Once a year

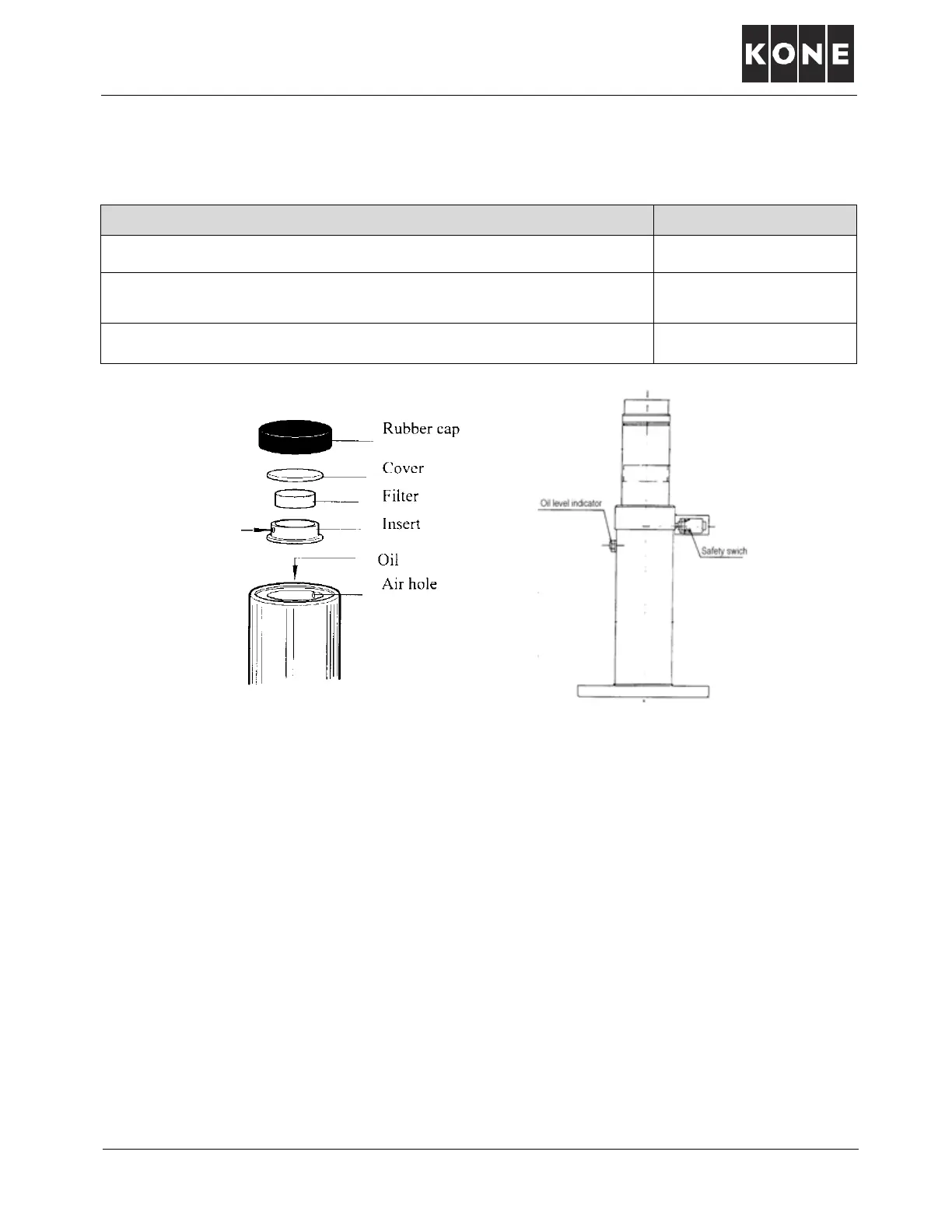

Oil Filling

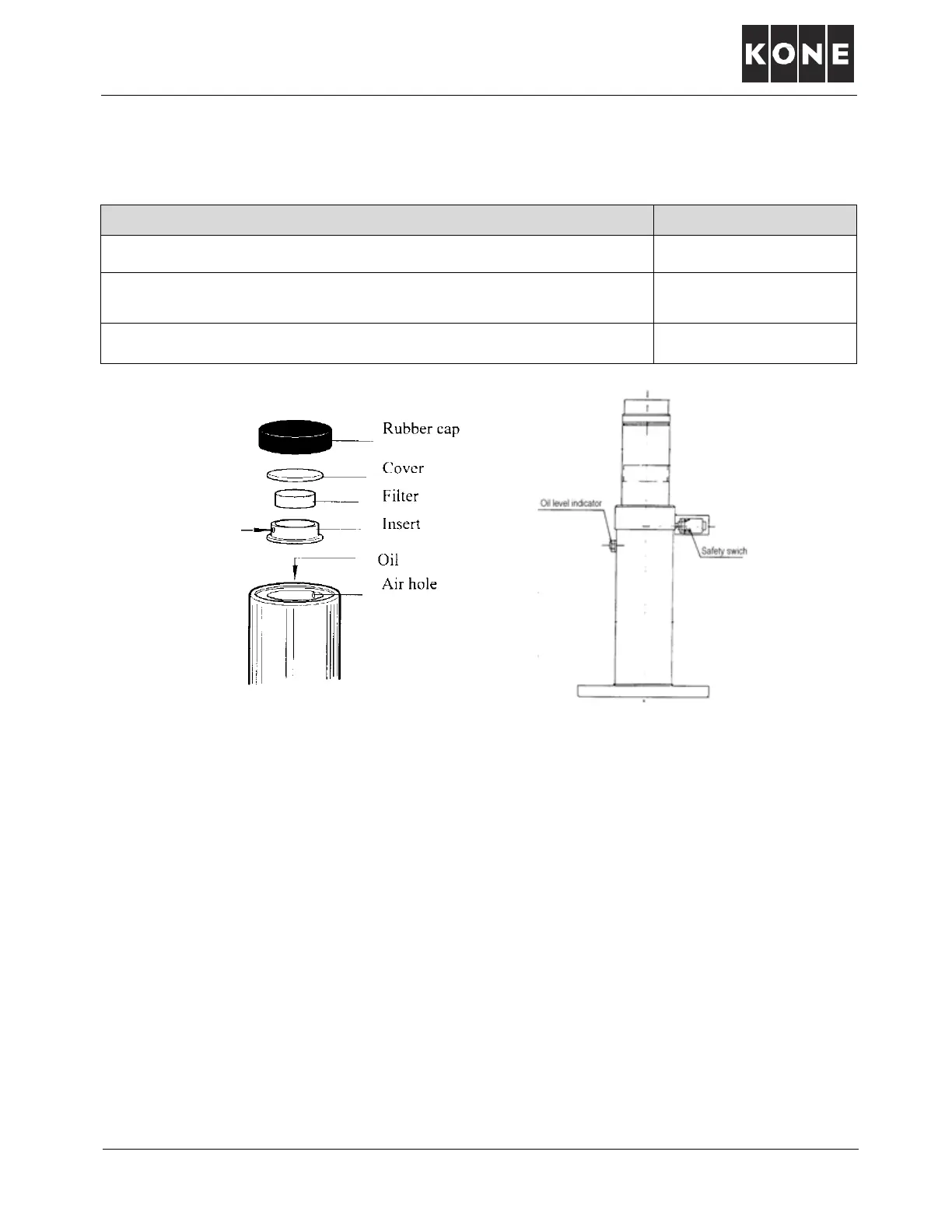

8.6.4.4.1: Check the oil level from the oil level indicator (see the figure on the right).

- If the oil level does not reach the oil level indicator, disassemble the piston top (see the figure

on the left) and fill in oil (OB buffers: ISO VG46, OLEO and YH buffers: ISO VG68).

- Install the piston top parts and let the buffer rest (piston compressed 40...50 mm).

- Re-check the oil level from the oil level indicator.

- If much oil (1 liter/year) is needed replace the buffer.

- Clean the pit if there has been an oil leak and handle the waste in line with a sound

environmental policy.

8.4.4.4.2: Clean the buffer plungers. Remove any paint or other substance that could possibly

interfere with its proper operation.

- Check alignment of the buffers to the strike plates. Correct any misalignment.

- Check security of all buffer fastenings. Tighten as required.

8.6.4.4.3: Do not store additional buffer oil in the pit or on the car top.

NOTE! Make sure that the hole is on the opposite side of the air hole when assembling.

Loading...

Loading...