KONE Maintenance Method

MX10 / MX20 MCP Procedures - ASME A17.1-2013 / CSA B44-13

© 2014 KONE Corporation PSK8-604-MX10/MX20

All rights reserved.

55 (-) 2014-12-15

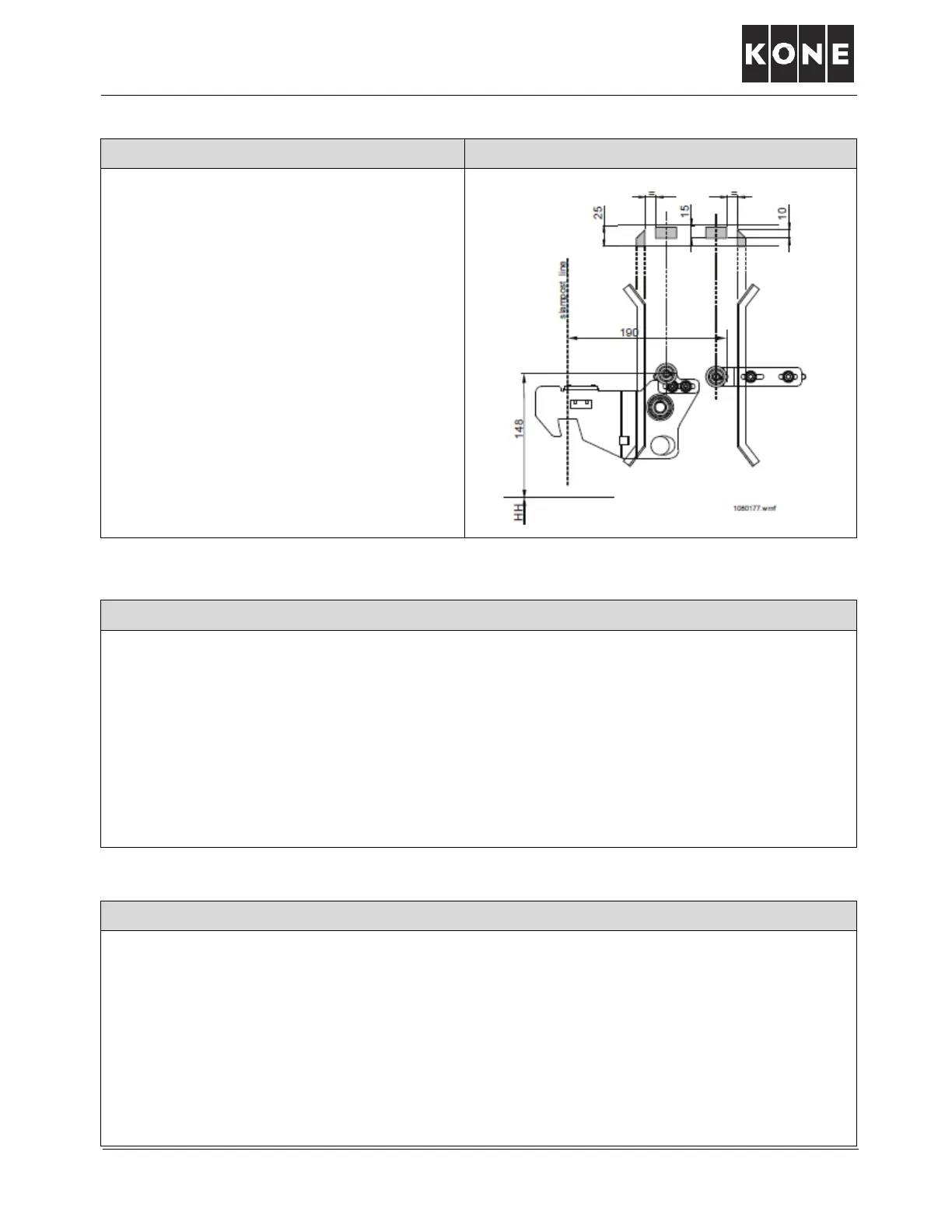

8.6.4.13 (i): Clutches, engaging vanes, retiring cams, and engaging rollers

Procedure Note

Operation of the following items should be as

follows:

• Lock rollers should be in the middle of

coupler vanes.

• Door coupling system should engage

properly, engagement with rollers.

• Door coupling system should operate

quietly.

• Lock rollers should rotate freely.

8.6.4.13.1 (f): Hangers, tracks, door rollers, up-thrusts, safety retainers

Procedure

Examine and maintain the hanger tracks

• Clean tracks of dirt and lubrication build-up, especially at the point the door rollers stop when

the door lock is latched.

• Check the condition of the tracks. Look for worn rolling surfaces, especially at the point the

interlock hook engages the interlock box. Replace tracks, if required.

• Lubricate tracks on freight elevators with 30w motor oil, as necessary.

• Check alignment of the tracks relative to the sills. Adjust the tracks if they are not parallel

to the sills.

8.6.4.13.1 (h): Sills, bottom guides, fastenings, condition, engagement

Procedure

Check hoistway door gibs, brackets, fire tabs and sills.

• Check door gibs and fire tabs for excessive wear and proper sill penetration. Adjust or replace

as required.

• Check fastenings. Tighten as required.

Check sills

• Check for excessive wear.

• Remove debris from sill.

• Check fastenings. Tighten as required.

Loading...

Loading...