Omega

37

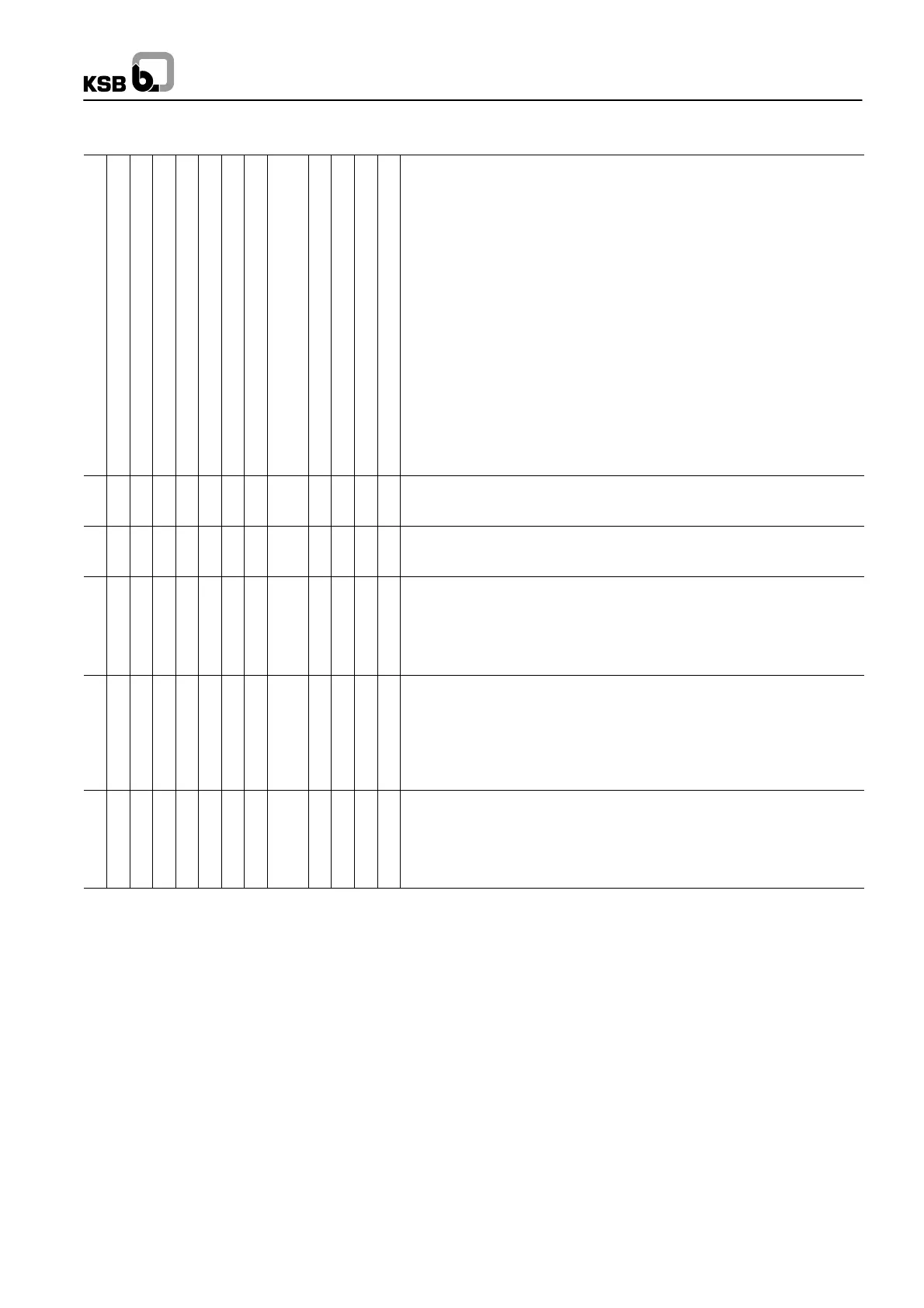

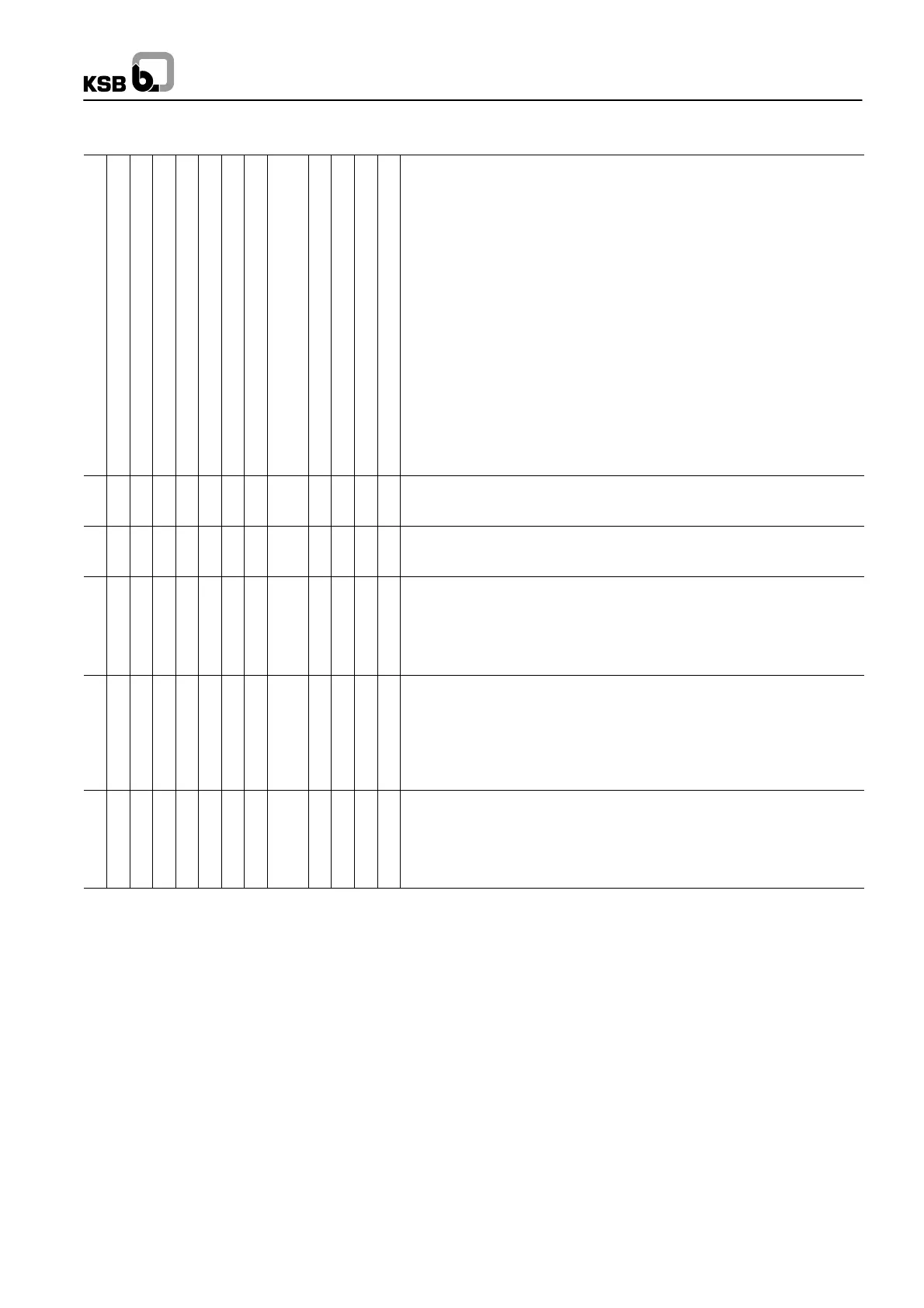

Trouble--shooting Table

Pump pressure too low

Pump pressure too high

Flow rate too high

Flow rate too low

Power consumption too high

Pump fails to pump liquid after being switched on

Pump ceases to pump liquid

Pump does not run smoothly (noise, vibrations)

Inadmissible temperature increase at pump /

seal casing

Bearing temperature too high

Exessive leakage at shaft seal

Drive overloaded

Leakage at pump

Cause Remedy

1

)

F F

Higher density or viscosity

of medium handled than

specified in the order

Reduce speed

In the case of persistent overloading, turn

down impeller, if necessary

1

)

.

F F F F F

Speed too high Reduce speed

In the case of persistent overloading, turn

down impeller, if necessary

1

)

.

F

Tie bolts / seals Check

Tighten tie bolts

Replace gaskets

Check pipe connections and pump moun-

ting, if necessary, improve mounting of pi-

ping.

F

Worn shaft seal Check flushing / sealing liquid pressure

clean sealing liquid line, possibly introduce

sealing liquid from an external source or

increase pressure

Replace shaft seal

Replace worn components

Replace shaft protecting sleeve.

F F F F

Unfavourable flow to suc -

tion nozzle of pump

Alter piping

If necessary, alter intake pipe if resistances

are too high

Check whether pipe routing results in twi-

sted or irregular flow (e.g. downstream of

an elbow) and correct, if necessary.

1

) Consult KSB

Loading...

Loading...