Omega

38

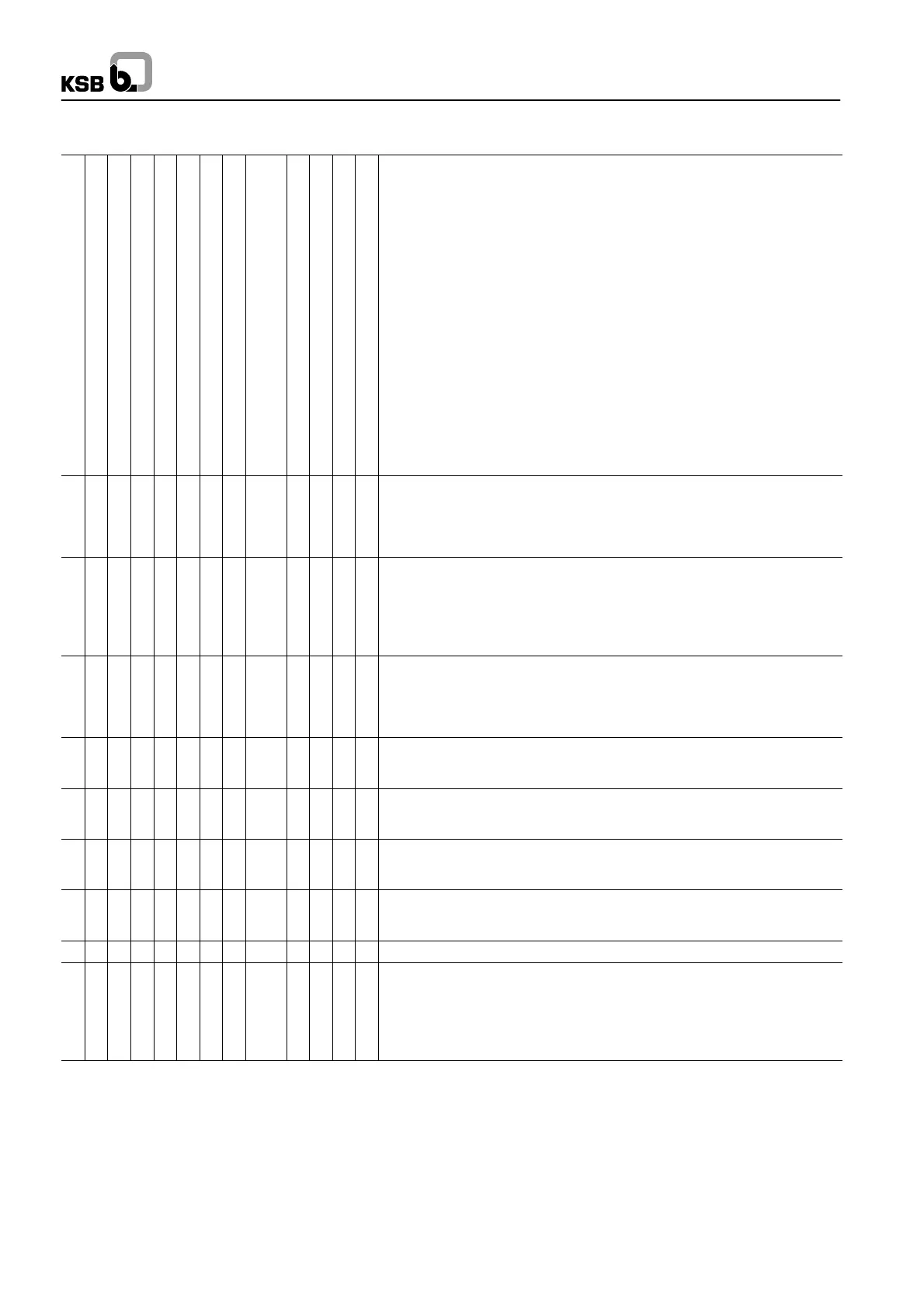

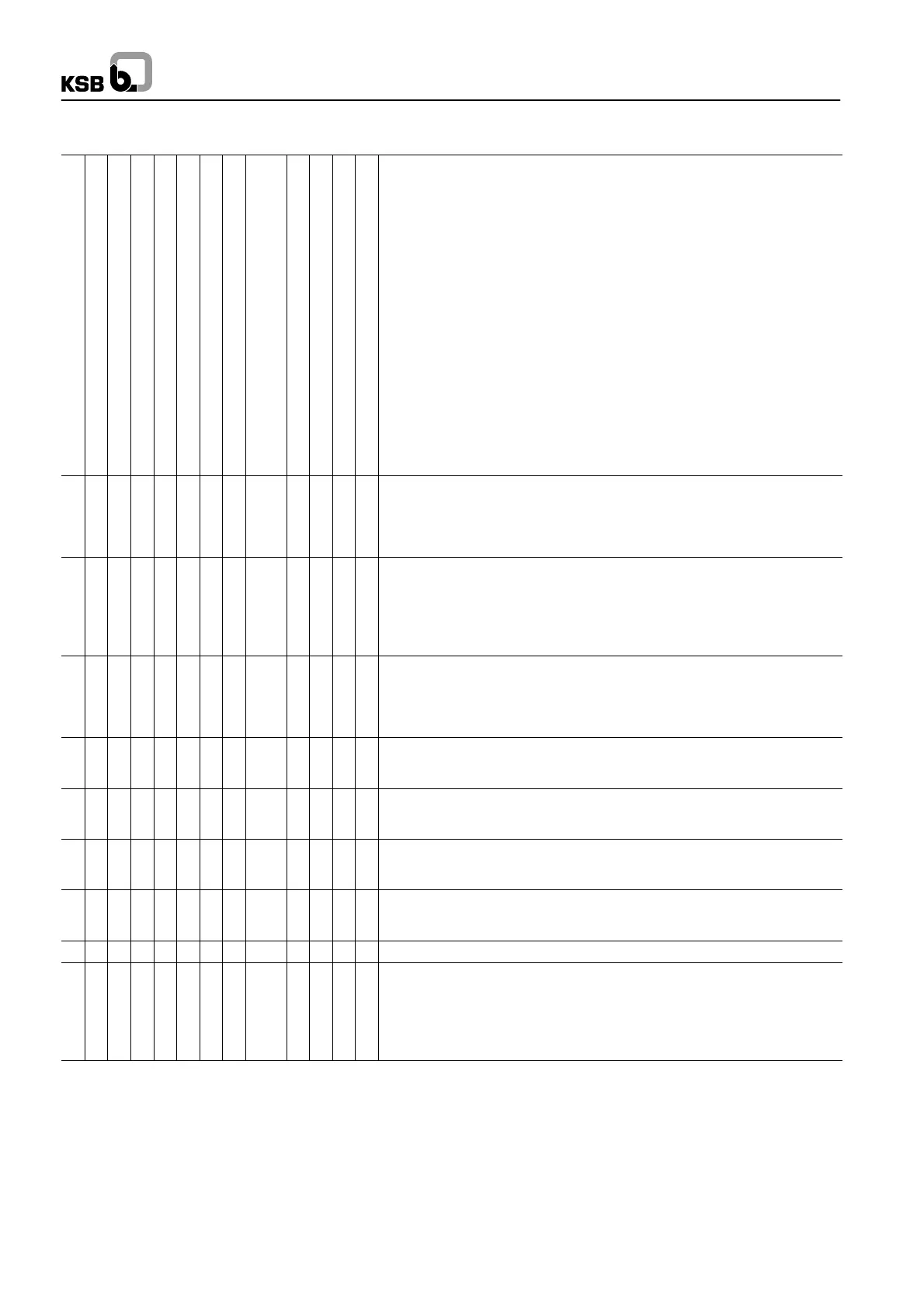

Trouble--shooting Table

Pump pressure too low

Pump pressure too high

Flow rate too high

Flow rate too low

Power consumption too high

Pump fails to pump liquid after being switched on

Pump ceases to pump liquid

Pump does not run smoothly (noise, vibrations)

Inadmissible temperature increase at pump /

seal casing

Bearing temperature too high

Exessive leakage at shaft seal

Drive overloaded

Leakage at pump

Cause Remedy

1

)

F F

Gland cover, seal cover

tightened incorrectly,

wrong packing material

Alter

Replace

Correct

Replace gland packing

Replace worn components

F F

Lack of cooling liquid or

cooling liquid chamber con-

taminated

Check flushing / sealing liquid pressure

Clean sealing liquid line, possibly introduce

sealing liquid from an external source or

increase its pressure

Increase cooling liquid flow

Clean cooling liquid line.

F F

Pump mis --aligned or reso-

nance vibrations in the pi-

ping

Re-- align pump / drive

Check piping connections and pump

mounting, if necessary, improve mounting

of piping

Apply vibration--damping measures

F

Excessive axial thrust Check duty point / pump selection

Check mode of operation

Check suction -- side flow.

F

Too little, too much or un-

suitable lubricant

Clean bearing

Replace lubricant

Top up, reduce or change lubricant

F F F F

Motor is running on two

phases only

Replace defective fuses

Check electrical connections

Check switchgear.

F F F

Rotor is out of balance Clean rotor

Check run--out, straighten if necessary

Re-- balance rotor.

F F F

Bearings damaged Replace / change

F F

Flow rate too low Re--adjust operating point

Fully open shut--off valve in the intake pipe

Fully open shut--off valve in the discharge

pipe

Recalculate or measure the hydraulic los-

ses H

V

.

1

) Consult KSB

Loading...

Loading...