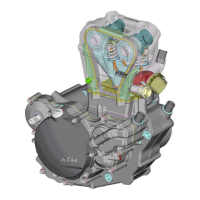

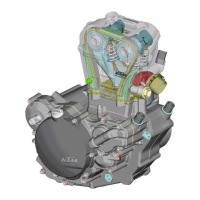

5-3C

Left housing half

Remove the shaft seal rings and use a hot plate to heat the housing half

to a temperature of approximately 150° C.

NOTE: At a temperature of 150° C it is usually sufficient to tap the

housing half onto a plane wooden surface and the bearings will simply

drop out of the bearing seats. However, in some cases it is necessary to

press the bearings out of their seats. To prevent damaging of the

bearings, the device used to press in the new bearings must be designed

in such a way that it touches only the outer ring of the bearing.

Roller bearing or the crankshaft

1

Apply a suitable mandrel on the outside to press the roller bearing

inwards. Insert a new roller bearing from the inside and press it all the

way into the seat.

Grooved ball bearing of the main shaft

2

Apply a suitable mandrel on the outside to press the grooved ball

bearing inwards. Insert a new grooved ball bearing from the inside and

press it all the way into the seat.

!

CAUTION

!

T

O PREVENT DAMAGING OF THE HOUSING, NEVER APPLY TOO MUCH FORCE WHEN

PRESSING IN GROOVED BALL BEARINGS

.

Grooved ball bearing of the countershaft

3

Apply a suitable mandrel on the outside to press the grooved ball

bearing inwards. Insert a new grooved ball bearing from the inside and

press it all the way into the seat.

Shaft seal ring of the countershaft

4

Insert a new shaft seal ring from the outside and press it in flush. Do not

forget the stop disc (position it on the grooved ball bearing of the

countershaft before mounting).

Needle bearing of the shifting shaft

5 (from model 2002 on)

Use a suitable mandrel to press out the needle bearing. Insert the new

needle bearing and press it all the way in.

Shaft seal ring of the shifting shaft

6

Insert a new shaft seal ring from the outside and press it in flush.

Shaft seal ring of the crankshaft

7

Insert a new shaft seal ring from the outside and press it in flush.

Lubrication bore of the crankshaft roller bearing

S

Check for obstructions and clean the bore with compressed air, if

necessary.

Check if the oil guiding rubber

8 of the left housing half is correctly

mounted (i.e. with the narrower end of the guide slots facing inwards)

and apply a small quantity of grease to fix it in the housing. Brittle or

hard oil guiding tubes must be replaced.

1

2

3

4

5

6

S

7

8

Loading...

Loading...