14. Appendix

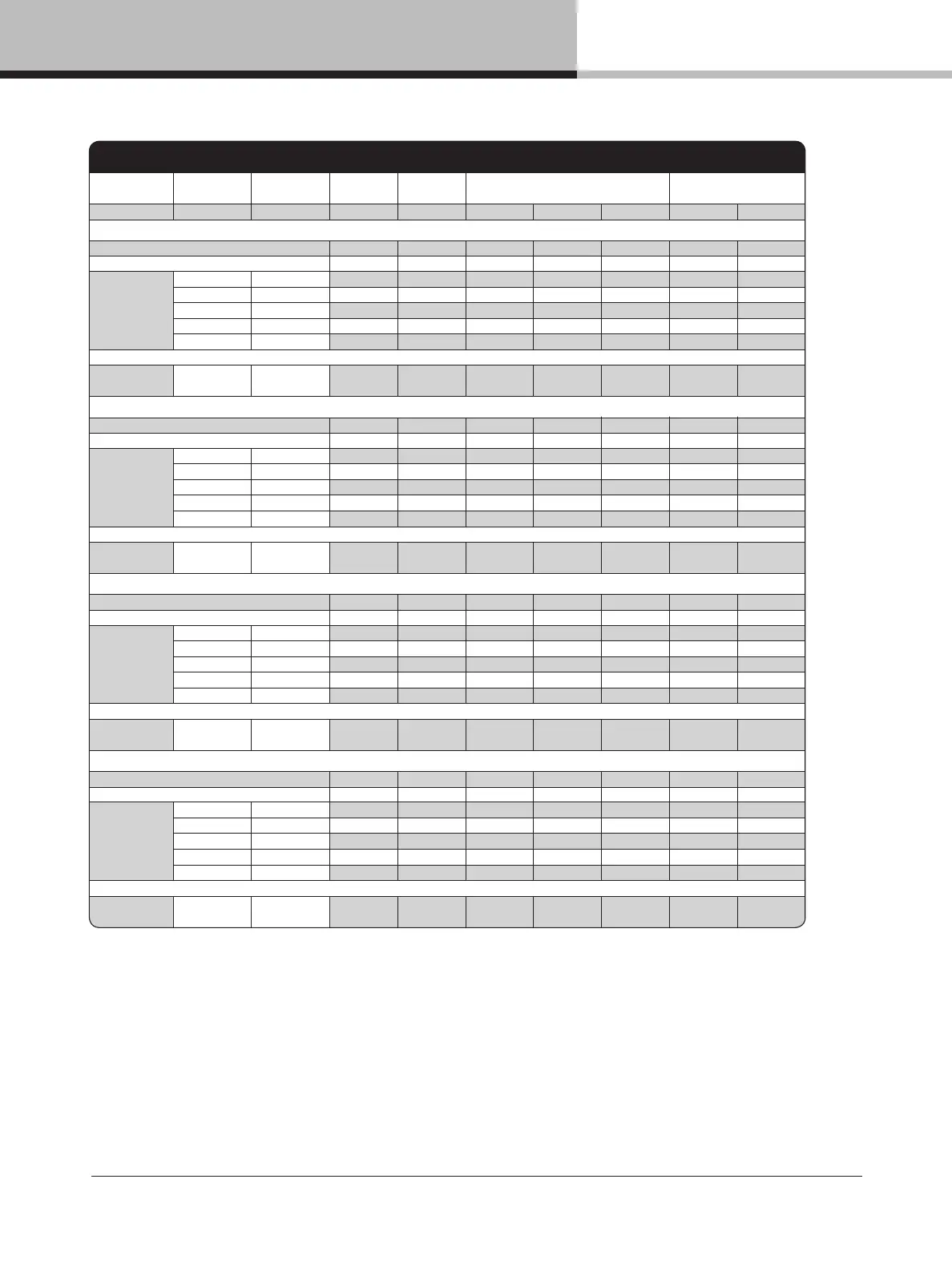

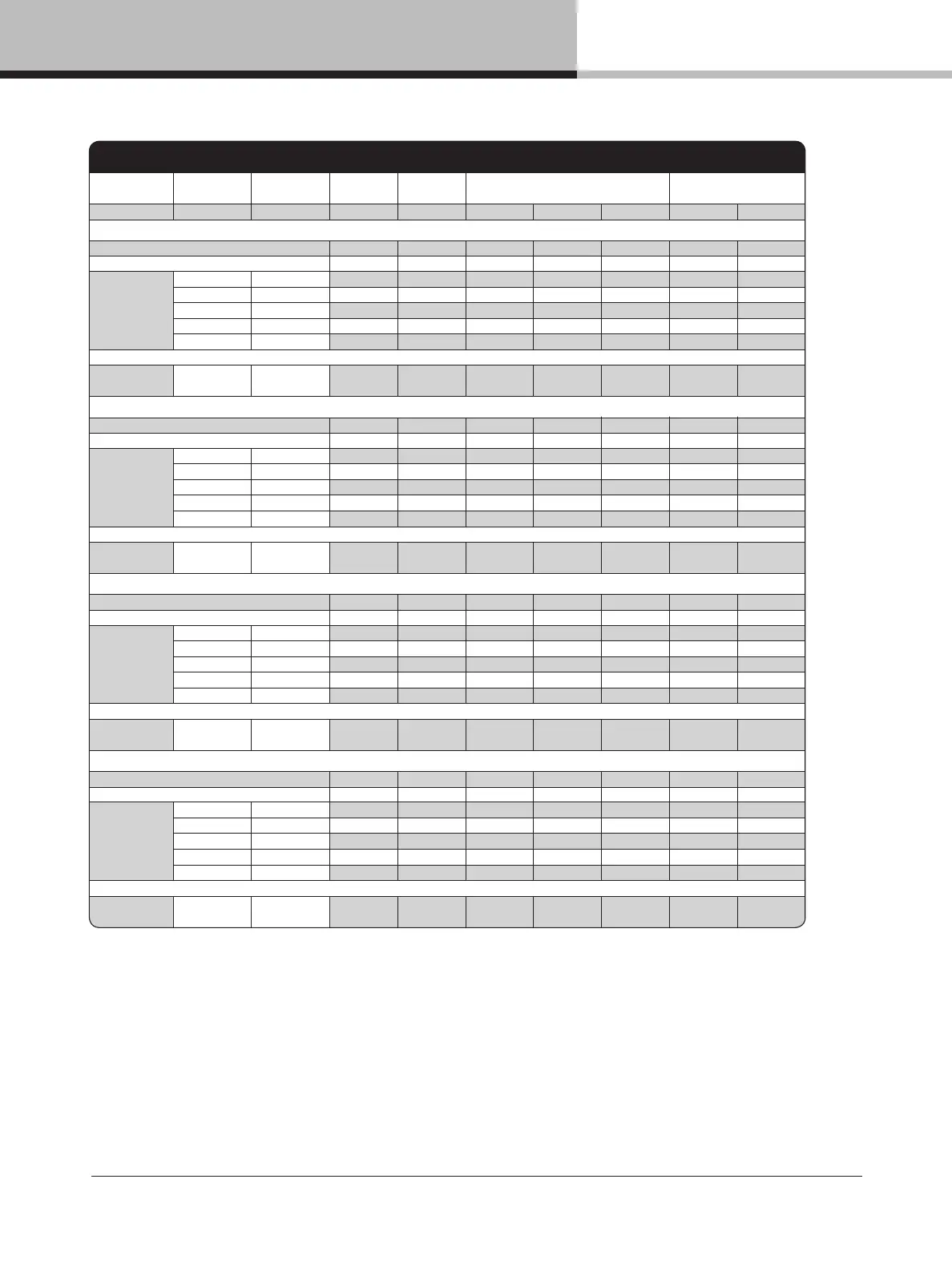

D SERIES 200:4

Level Load

Rated power

per channel

Line Current

Power

Factor

Measured Power (W) Thermal Dissipation

(A) (%) In Out Dissipated BTU/hr kCal/hr

Mains Voltage 100 VAC, 30 A

Standby 0.3 52 17 0 17 58 15

Power on, Idling 2.4 97 235 0 235 802 202

Pink Pseudo

Noise

16 Ω / Ch. 1150 12.1 99 1192 588 604 2061 520

8 Ω / Ch. 2300 22.3 99 2198 1174 1024 3493 881

4 Ω / Ch. 4400 29.2 99 2853 1478 1375 4691 118 3

2.67 Ω / Ch. 5000 29.2 99 2862 1399 1463 4991 1259

2 Ω / Ch. 4400 29.1 99 2826 1355 1472 5022 1266

LoadPilot

Sine 20 kHz

8 Ω / Ch. 2

.5 97 236 0 236 807 203

Mains Voltage 120 VAC, 30 A

Standby 0.3 48 17 0 17 58 15

Power on, Idling 2.0 97 227 0 227 775 195

Pink Pseudo

Noise

16 Ω / Ch. 1150 12.0 99 118 0 588 593 2023 510

8 Ω / Ch. 2300 18.4 99 2144 1174 970 3310 835

4 Ω / Ch. 4400 30.0 99 3457 1896 1561 5326 1343

2.67 Ω / Ch. 5000 29.5 99 3439 1752 1687 5756 1451

2 Ω / Ch. 4400 29.9 99 3495 1665 1830 6245 1575

LoadPilot

Sine 20 kHz

8 Ω / Ch. 2.0 97 232 0 232 790 199

Mains Voltage 208 VAC, 17.3 A

Standby 0.3 27 18 0 18 60 15

Power on, Idling 1.2 92 222 0 222 757 191

Pink Pseudo

Noise

16 Ω /

Ch. 115 0 5.7 99 1151 588 564 1923 485

8 Ω / Ch. 2300 10.2 99 2055 1174 881 3005 758

4 Ω / Ch. 4400 16.2 99 3286 1948 1338 4565 1151

2.67 Ω / Ch. 5000 15.6 99 3171 1752 1419 4843 1221

2 Ω / Ch. 4400 16.0 99 3253 1665 1589 5420 1367

LoadPilot

Sine 20 kHz

8 Ω / Ch. 1.2 92 229 0 229 780 197

Mains Voltage 230 VAC, 16 A

Standby 0.3 23 18 0 18 61 15

Power on, Idling 1.2 92 222 0 222 757 191

Pink Pseudo

Noise

16 Ω / Ch. 1150 5.1 98 1134 588 546 1863 470

8 Ω / Ch. 2300 9.2 99 2053 1174 879 2999 756

4 Ω / Ch. 4400 15.9 99 3529 2109 1420 4845 1222

2.67 Ω / Ch. 5000 16.0 99 3564 1935 1630 5561 1402

2 Ω / Ch. 4400 16.0 99 3577 1856 1722 5875 1481

LoadPilot

Sine 20 kHz

8 Ω / Ch. 1.1 90 228 0 228 777 196

14. Appendix

48

D SERIES Lake Operation Manual rev 3.0.3

14.3. Maintenance

During normal operation a D Series device provides trouble–free service. If the front panel display requires cleaning,

use a soft cloth only; do not use solvent cleaners.

The dust lters on both sides of the front panel, behind the grilles, should occasionally be removed and cleaned to

ensure maximum airow through the device. Disconnect the unit from mains power prior to removing dust the lter,

and ensure the dust lter is replaced prior to turning the unit back on.

In extreme cases it may be necessary to clean the inside of the device. This procedure should only be carried out

by qualied service personnel. Internal cleaning may be necessary if the device has had prolonged operation in an

extreme environment such as one where cracked oil smoke machines are in use. If the device is used in extreme

conditions, it is recommended to have it serviced every three years as a preventative measure.

Loading...

Loading...