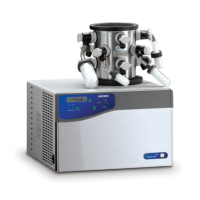

FreeZone

®

Plus

™

4.5 Liter Cascade

Freeze Dry Systems

Models

7386020 7387020

7386021 7387021

7386030 7387030

7386031 7387031

7386040 7387040

7386041 7387041

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

To receive important product updates,

complete your product registration card

online at register.labconco.com

User’s Manual

Please read the User’s Manual before operating the equipment.