Chapter 3: Getting Started

Product Service 816-333-8811 or 1-800-522-7658

11

Electrical Connection

Plug the power cord into the receptacle on the back of the freeze dryer and

plug the other end into a suitable power receptacle.

Drying Chamber or Drying Manifold Installation

Install the clear lid with 3.0 inch hole on top of the collector chamber.

The supplied drying chamber or drying manifold, which may be purchased

separately, may be positioned directly above the 3-inch hole in the collector

chamber lid. Center the rubber gasket that came with the chamber over the

hole in the lid. Then place the chamber over the gasket. When vacuum is

applied to the system, the chamber will be held securely in place.

Chemical Resistance of Freeze Dryer

Components

The FreeZone Freeze Dry System is designed to be chemically resistant to

most compounds that are commonly used in freeze drying processes.

However, by necessity, the freeze dryer is comprised of a number of different

materials, some of which may be attacked and degraded by certain chemicals.

The degree of degradation is dependent on the concentration and exposure

duration. Some of the major components of the FreeZone Freeze Dry System

that are susceptible to degradation are as follows:

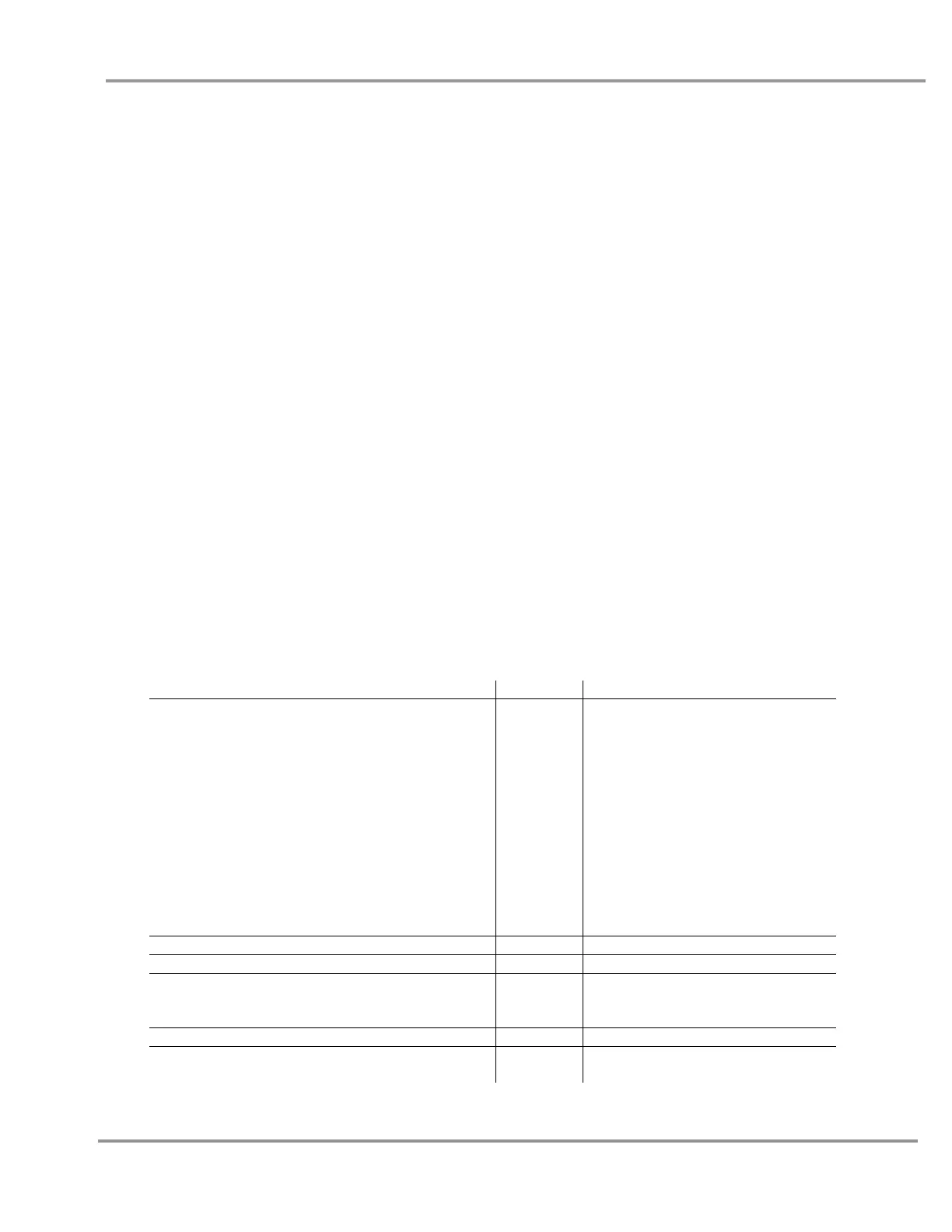

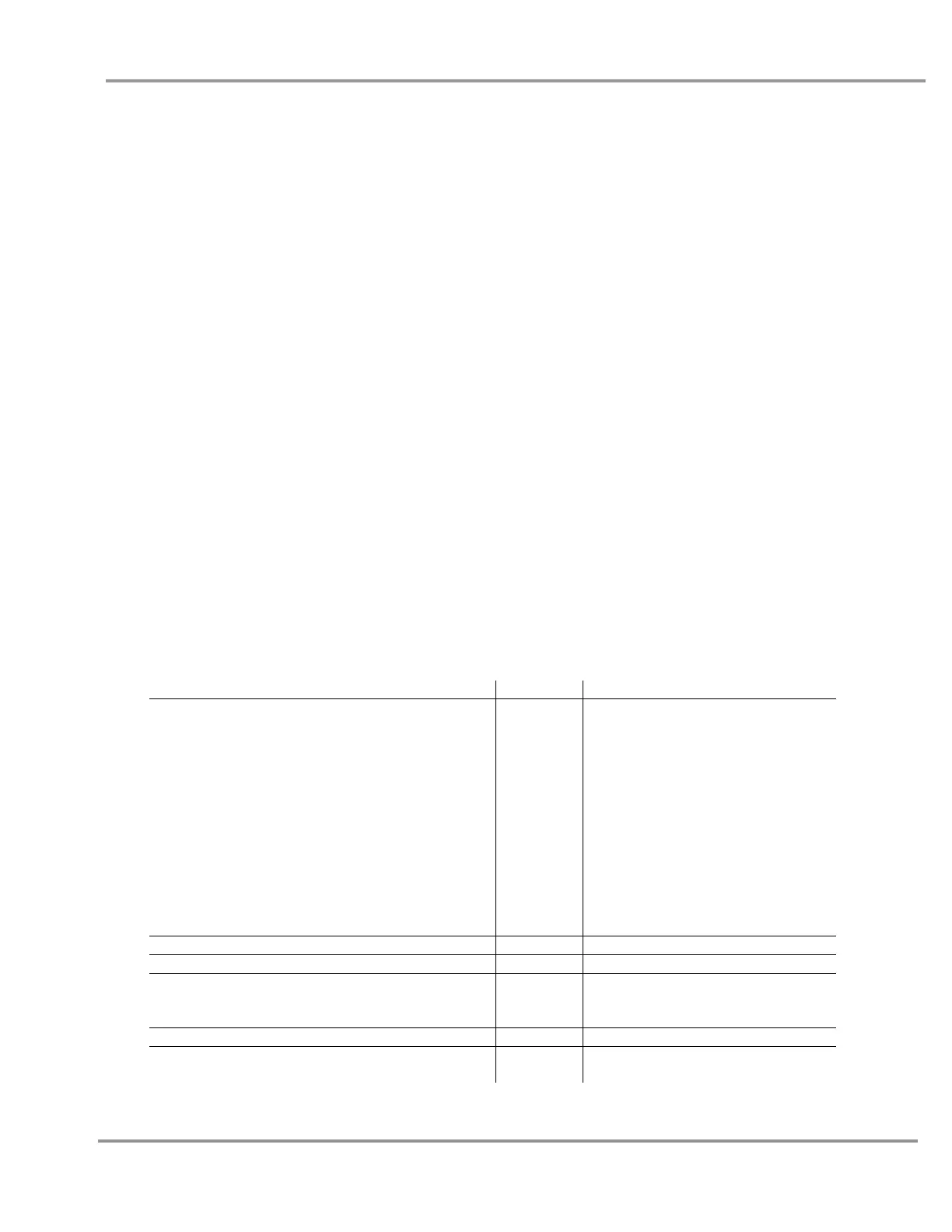

Acids Buffers Solvents

Component Material

Acetic Acid 20%

Formic Acid

Trifluoroacetic Acid (TFA)

Calcium Chloride

Sodium Phosphate

Acetone

Acetonittirle

Carbon Tetrochloride

Cyclohexane

Dioxane

Methyl t-Butyl Ether (BTBE)

Pyridine

Valve Stem Acetal (Delrin) C D D D D

Collector Lid Acrylic D D D D

Hoses, Gaskets

& Valve

Bodies

Neoprene C D D C C D D D C D

Flask Top Silicon Rubber C D D D D D C D

Chamber &

Fittings

Stainless Steel C

Loading...

Loading...