103

Tires

Before each tow, be sure the tire pressure is at the

value indicated on the Certification/VIN label.

Tire pressure must be checked while the tire is cold.

Do not check the tire pressure immediately after

towing the trailer. Allow at least three hours for a tire

to cool, if the trailer has been towed for as much as

one mile. Replace the tire before towing the trailer if

the tire treads have less than 1/16 inch depth or the

telltale bands are visible.

A bubble, cut or bulge in a side wall can result in a

tire blowout. Inspect both side walls of each tire for

any bubble, cut or bulge; and replace a damaged tire

before towing the trailer.

WARNING

Worn, damaged or under-inflated tires can

cause loss of control, injury and damage.

Check tires before each tow.

Wheel Rims

If the trailer has been struck, or impacted, on or near

the wheels, or if the trailer has struck a curb, inspect

the rims for damage (i.e. being out of round); and

replace any damaged wheel. Inspect the wheels for

damage every year, even if no obvious impact has

occurred.

Never install aftermarket wheels or lug nuts on

your trailer. Use only original equipment wheels and

lugs nuts. Aftermarket wheels and lug nuts may not

meet the load carrying requirements, pressure capac-

ity and offset as the original equipment.

Wheel Bearings

A loose, worn or damaged wheel bearing is the most

common cause of brakes that grab.

To check your bearings, jack trailer and check wheels

for side-to-side looseness. If the wheels are loose, or

spin with a wobble, the bearings must be serviced or

replaced.

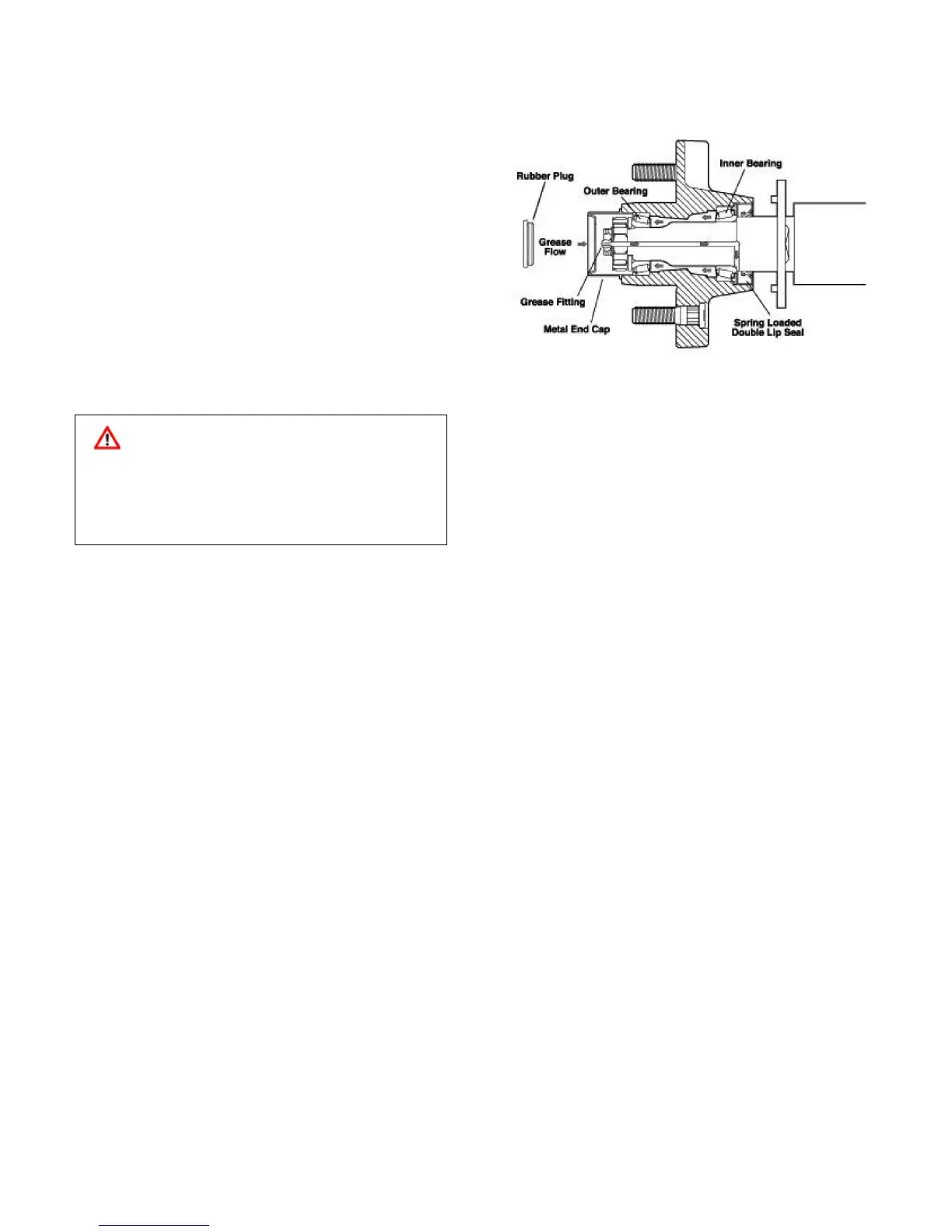

Your trailer is equipped with grease fitting lubricated

bearings.

Grease Fitting Lubricated Bearings

Bearings should be lubricated every 12 months or

12,000 miles, whichever occurs first.

• Removetherubberplugfromthehubend.

• Placeastandardgreasegunontothegrease

fitting. Make sure the grease gun nozzle is fully

seated on the fitting.

• Pumpgreaseintothefittingwhilerotatingbegin

to flow back out to the cap around the grease

gun nozzle.

• Stopwhennewgreaseisobserved.

• Wipeoffexcessandinstallrubberplug.

Lug Nuts

Lug nuts are prone to loosen right after a wheel is

mounted to a hub. When driving on a remounted the

first 10, 25 and 50 miles of driving and before each

tow thereafter.

Lug Nut Tightening (Torque)

Being sure wheel mounting nuts (lug nuts) on trailer

wheels are tight and properly torqued is an impor-

tant responsibility that trailer owners and users need

to be familiar with and practice. Inadequate and/or

inappropriate wheel nut torque (tightness) is a major

reason that lug nuts loosen in service. Loose lug nuts

can rapidly lead to a wheel separation with potentially

serious safety consequences.

• Becertainyouhaveaclearunderstandingof

the specific wheel maintenance responsibili-

ties your vehicle manufacturer requires/rec-

ommends you, as the owner, must perform in

order to insure your wheel equipment is safely

maintained. Check the lug nut tightness the first

10, 25 and 50 miles of driving and before each

tow thereafter. Refer to the owner’s manual and

speak with your dealer if you have any ques-

tions about proper tightening practices.

Loading...

Loading...