BOX JOINTS

60

Chapter 14 Super Jig-12-18-24 User Guide

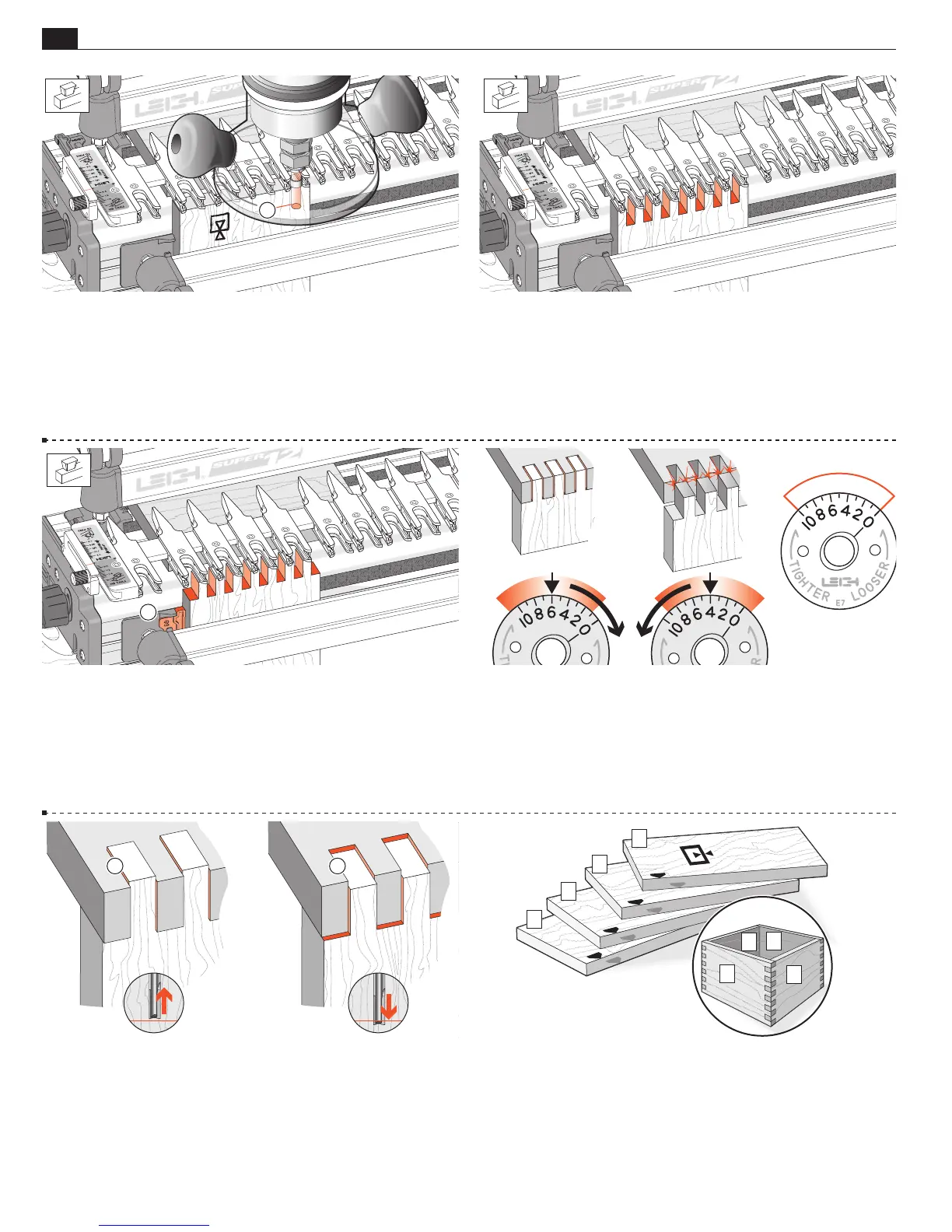

14-7 Lower the finger assembly onto the spacer board and double-

check that the bit depth is down to the center of the pencil line

.

Make sure the collet does not rub on the guidebush.

1

14-8 Rout one end of the scrap board. Rout into each finger

opening and between each finger. Make sure to run the guidebush

on both sides of each opening.

14-9 Remove the board and fit the Spacer to the front side stop

with the number 2 showing

. Make sure it is fully home.

Clamp the second test board with its side edge against the Spacer

and its top edge touching the guidefingers. Rout this board.

Note: Square ended boards are essential to achieve flush joint alignment.

1

14-10 Test the two boards for fit and flushness. If the joint is

loose, turn the e7-Bush to a higher number, say “6” and rout two

more board ends. If the joint is too tight, turn the e7-Bush to a

lower number, say “4”. Trial and error establish the best e7-Bush

setting and record this in the space provided here, and/or on the

pull-out. Next time this setting will get a good first-time result

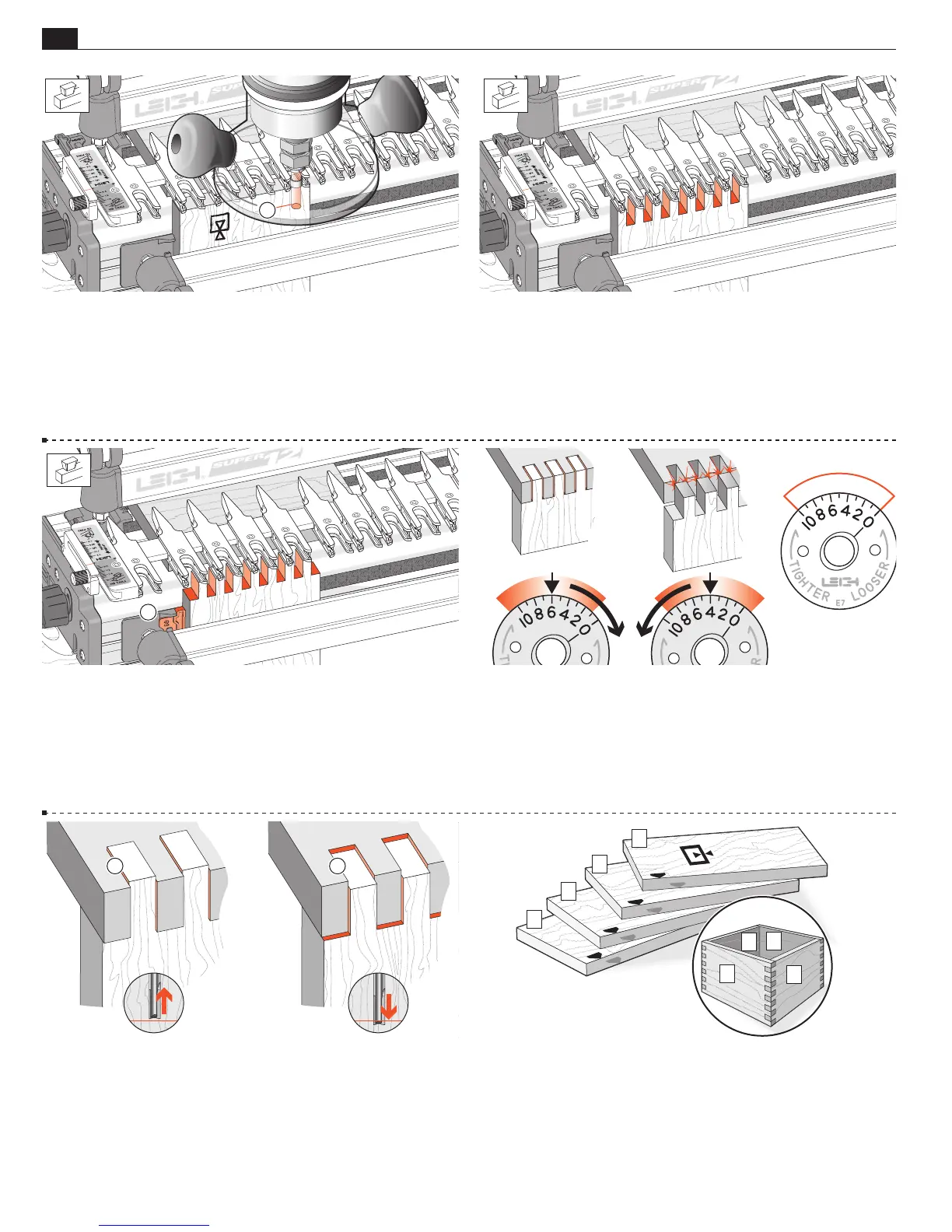

14-11 If the joint is over-flush

, raise the bit slightly. If it is

under-flush

, lower the bit.

1 2

14-12 Let’s make a box.

Prepare four boards and number them 1 to 4. Then select the grain

alignment and mark the common top (or bottom) edge. Don’t

worry about face side selection; this can be done after routing.

4

3

2

3

2

1

4

1

Loading...

Loading...