Page 13

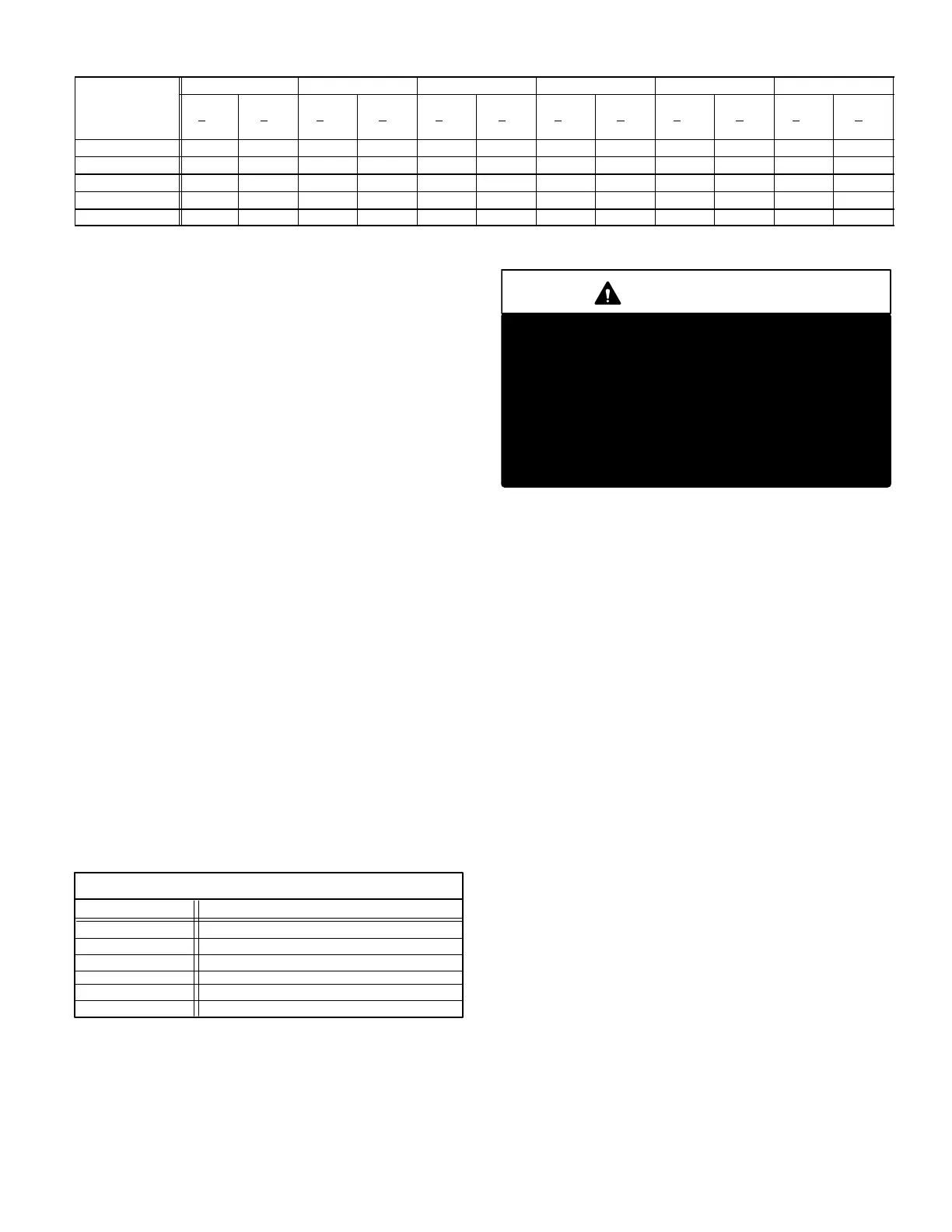

TABLE 7

Outdoor Coil

12HPB24 12HPB30 12HPB36 12HPB42 12HPB48 12HPB60

Air Entering

Temp.

_F (_C)

liq.

+

10

PSIG

vap.

+

5

PSIG

liq.

+

10

PSIG

vap.

+

5

PSIG

liq.

+

10

PSIG

vap.

+

5

PSIG

liq.

+

10

PSIG

vap.

+

5

PSIG

liq.

+

10

PSIG

vap.

+

5

PSIG

liq.

+

10

PSIG

vap.

+

5

PSIG

65 (183.) 144 78 140 76 152 74 152 75 146 75 146 73

75 (23.9) 170 79 164 77 178 76 179 76 171 77 175 74

85 (29.4) 199 80 194 78 208 77 210 77 198 78 206 75

95 (35) 228 81 224 79 238 78 241 78 229 79 237 76

105 (40.6) 261 82 259 80 275 81 278 79 268 81 275 77

NOTE − Typical pressures only. Indoor evaporator match up, indoor air quantity, and evaporator load will cause the pressures to vary.

SUBCOOLING METHOD (TXV SYSTEMS)

(Ambient Temperature Below 60_F [16_C]

NOTE- It may be necessary to restrict air flow in order to

reach liquid pressures in the 200-250 psig range which

are required for checking charge. The indoor temperature

should be above 70_F (21_C). Block equal sections of air

intake panels, moving obstructions sideways until liquid

pressures in the 200-250 psig range are reached.

1 − Connect gauge manifold. Connect an upright R−22

drum to center port of gauge manifold.

2 − Operate indoor and outdoor units in cooling mode.

Allow outdoor unit to run until system pressures sta-

bilize.

3 − Make sure thermometer well is filled with mineral oil

before checking liquid line temperature.

4 − Read liquid line pressure and convert to con-

densing temperature using temperature/pres-

sure conversion chart.

Condensing temperature (read from gauges)

should be warmer than the liquid line tempera-

ture.

5 − Place thermometer in well and read liquid line tem-

perature. Table 8 shows how much warmer the con-

densing temperature should be.

Add refrigerant to lower liquid line temperature.

Recover refrigerant to raise the liquid line tem-

perature.

6 − When unit is properly charged liquid line pres-

sures should approximate those given in table

7.

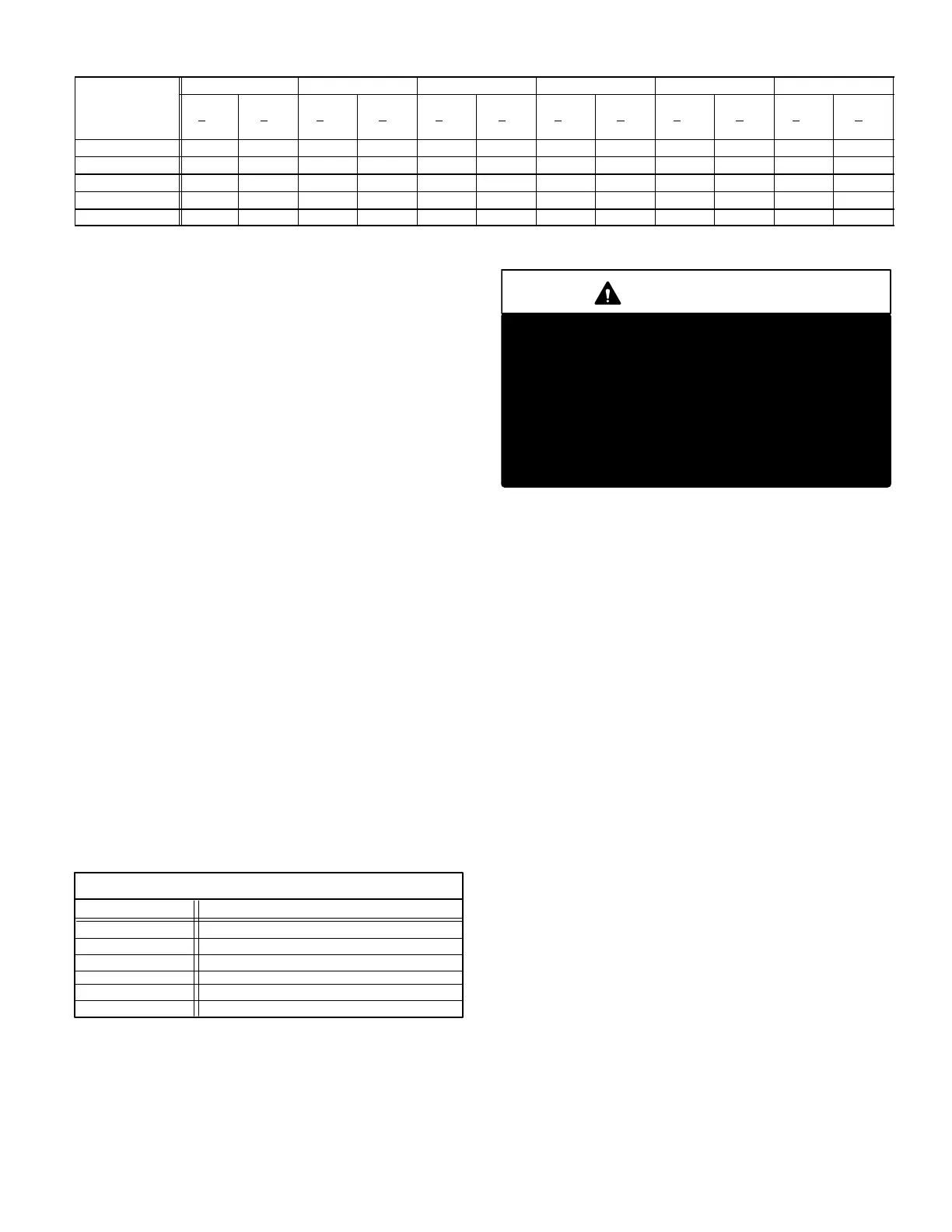

TABLE 8

Model Condensing Temp°F Warmer Than Liquid Line

12HPB24

12HPB30

12HPB42

12HPB48

12HPB60

SUBCOOLING METHOD

AMBIENT TEMPERATURE BELOW 60 _F (16 _ C)

11°F (6.1°C)

5°F (2.8°C)

4°F (2.2°C)

4°F (2.2°C)

6°F (3.3°C)

12HPB36 3°F (1.7°C)

IMPORTANT

Use table 7 as a general guide for performing mainte-

nance checks. Table 7 is not a procedure for charg-

ing the system. Minor variations in these pressures

may be expected due to differences in installations.

Significant deviations could mean that the system is

not properly charged or that a problem exists with

some component in the system. Used prudently,

table 7 could serve as a useful service guide.

E − Oil Charge

See compressor nameplate.

IV − MAINTENANCE

At the beginning of each heating or cooling season, the

system should be cleaned as follows:

A − Outdoor Unit

1 − Clean and inspect condenser coil. (Coil may be

flushed with a water hose).

NOTE − Make sure all power is disconnected before

flushing coil with water.

2 − Visually inspect all connecting lines, joints and

coils for evidence of oil leaks.

NOTE-Outdoor fan motors are permanently

lubricated.

B − Indoor Coil

1 − Clean coil if necessary.

2 − Check connecting lines and coil for evidence of oil

leaks.

3 − Check condensate line and clean if necessary.

C − Indoor Unit

1 − Clean or change filters.

2 − Bearings are pre-lubricated and need no further oil-

ing.

3 − Check all wiring for loose connections.

4 − Check for correct voltage at unit.

5 − Check amp−draw on blower motor.

Loading...

Loading...