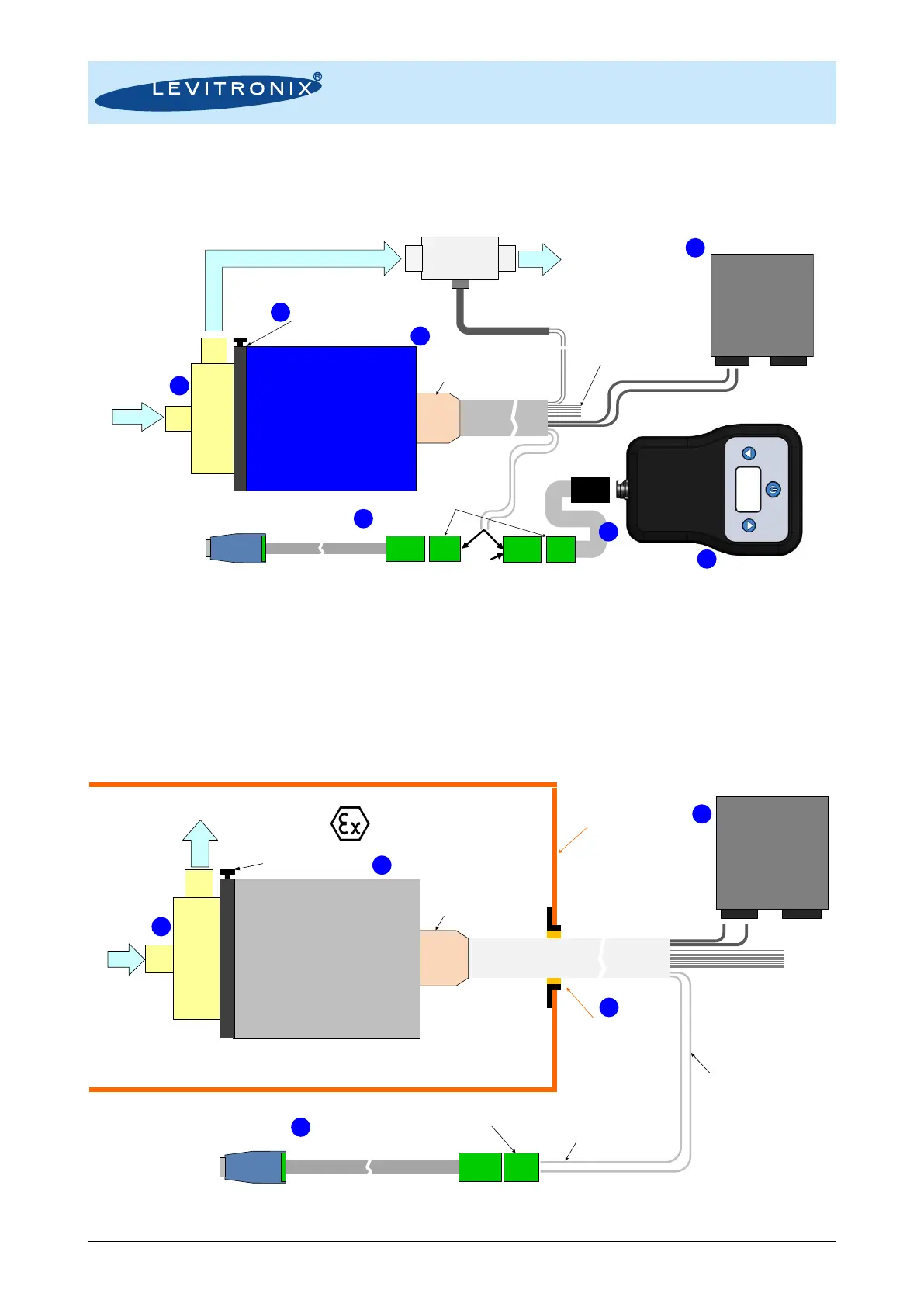

The PLC interface of the OEM model enables the implementation of precise closed loop flow or pressure

control in connection with either a flow or pressure sensor (see Figure 8). Precise ultrapure flow control

systems can be realized in combination with LEVIFLOW

®

flowmeters.

Figure 8: System configuration of OEM model for process control

(Pressure or flow control with external sensor, details in Section 4.3.1)

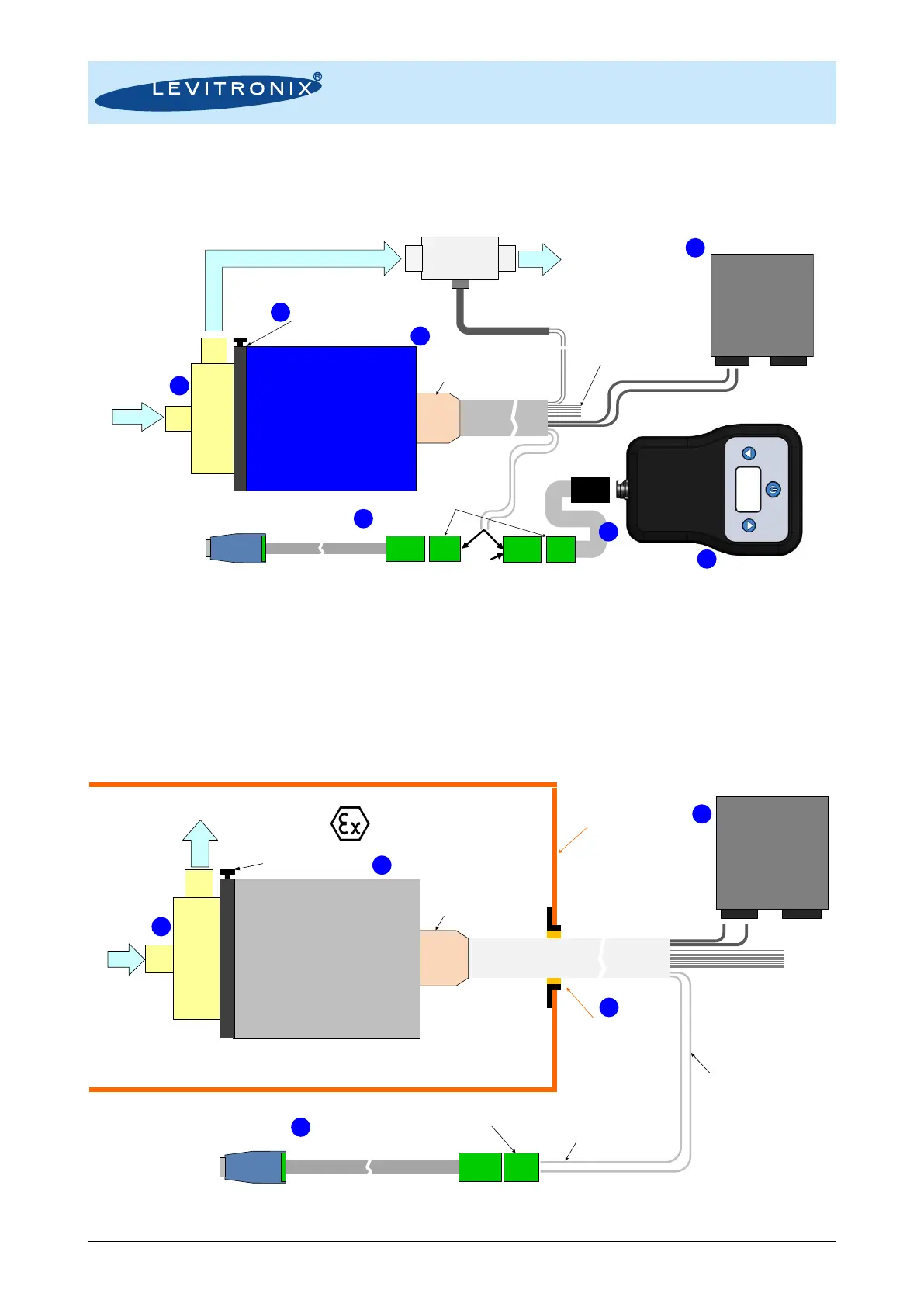

2.2.4 System Configuration for OEM ATEX / IECEx Models

Together with the defined pump heads an ATEX / IECEx certified pump driver allows installation of the pump

within an Ex classified area (see Figure 9 and Figure 10). One option to lead the driver cable outside of the

Ex area is to use an Ex certified cable sealing system as listed in Table 3.

Figure 9: System configuration of OEM Ex model for speed control

Integrated Ex Pump Driver

OEM Model

Outlet

Inlet

PLC Interface:

- Analog and Digital IO s

- Remote Control with Speed Signal

- Flowcontrol with external Sensor

- Pressure Control with ext. Sensor

AC/DC

Power

Supply

(DIN-Rail)

AC InputDC Output

PC Connection:

- System configuration

- Service and Firmware update

- Monitoring

Open Wires

Fieldbus Interface:

- Remote control with fieldbus

- Connection to PC

Screw type connector for

open-wires connection included in

converter cable package.

Fieldbus

RS485 of Driver

Integrated Driver Cable

Cable Bushing

DC Supply 24 V

USB to RS485

Converter with Cable

Cabinet Boundary for

Ex classified Area

Ex conform cable

sealing system

Ex classified

Location

Single

-Use

Pump Head

Bayonet Socket

with Locking Pin

Loading...

Loading...