29

General Installation Guidelines

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

GENERAL INSTALLATION GUIDELINES

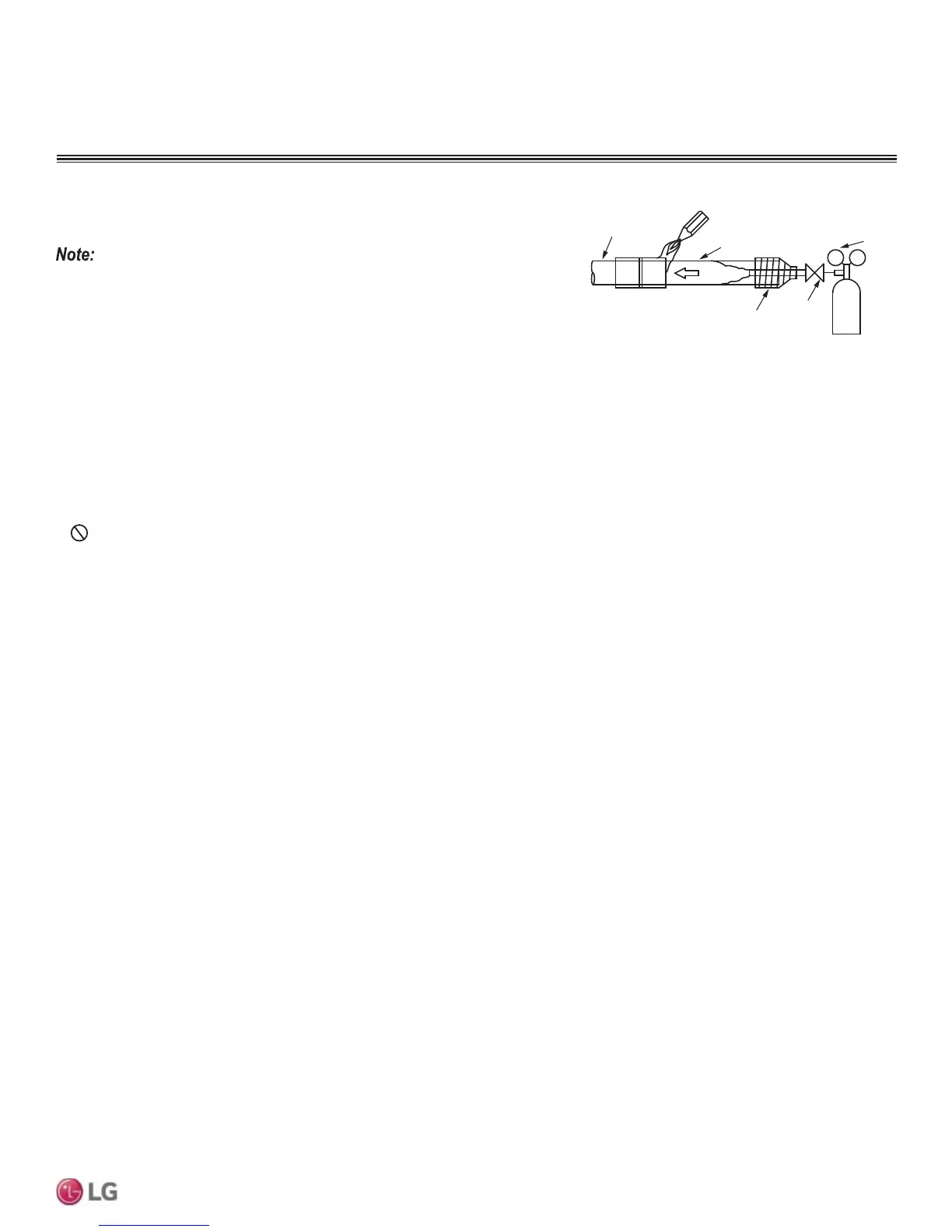

Figure 33: Refrigerant Pipe Brazing.

Pressure-reducing

Valve

Valve

Taping

Nitrogen

Pipe to

be brazed

Refrigerant

Piping

Brazing Practices

Piping Materials and Handling

All joints are brazed in the field. Single Zone refrigeration system components contain very small capillary tubes, small orifices, electronic

expansion valves, oil separators, and heat exchangers that can easily become blocked. Proper system operation depends on the installer

using best practices and utmost care while assembling the piping system.

• While brazing, use a dry nitrogen purge operating at a minimum pressure of three (3) psig and maintain a steady flow.

• Blow clean all pipe sections with dry nitrogen prior to assembly.

• Use a tubing cutter, do not use a saw to cut pipe. De-burr and clean all cuts before assembly.

• Store pipe stock in a dry place. Keep pipe capped and clean.

• Use adapters to assemble different sizes of pipe.

•

Do not use flux, soft solder, or anti-oxidant agents.

• Use a 15% silver phosphorous copper brazing alloy to avoid overheating and produce good flow.

• Protect isolation valves, electronic expansion valves, and other heat-sensitive control components from excessive heat with a wet rag or a

heat barrier spray product.

Keep the piping system free of contaminants and debris such as copper burrs, slag,

or carbon dust during installation. Contaminants can result in mechanical failure of the

system.

Refrigerant Piping System Insulation

All refrigerant piping from the outdoor unit to the indoor unit must be insulated correctly for safety and usage. Refrigerant piping, service

valves, and elbows must be properly and completely insulated using closed cell pipe insulation (up to the indoor unit piping connections).

To prevent heat loss / heat gain through the refrigerant piping, all refrigerant piping including liquid lines and vapor lines shall be insulated

separately. Insulation shall be a minimum 1/2Ǝ thick, and thickness may need to be increased based on ambient conditions and local codes.

Inside the outdoor unit, maximum pipe temperature is 248°F and minimum pipe temperature is -40°F. For field insulation of refrigerant piping

between outdoor units and indoor units, consider the following pipe temperature ranges for an operating heat pump system:

• Heating mode refrigerant temperature ranges: Liquid 75-118°F; High Pressure Vapor 95-220°F

• Cooling mode refrigerant temperature ranges: Liquid 75-118°F; Low Pressure Vapor 40-90°F

Loading...

Loading...