150 151

_TROUBLE SHOOTING GUIDE BOOK _

1. The Phenomena from Main Component Failure

- 84 -

Copyright ©2017 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. The phenomena from main component failure

The phenomena from main component failure

When system fault occurs, the error code is displayed on the indoor unit display or remote control display. The

trouble shooting guide is available in the service manual.

• When CH05/53/11 ERROR occurs, check if auto-addressing has done and communication wiring is ok.

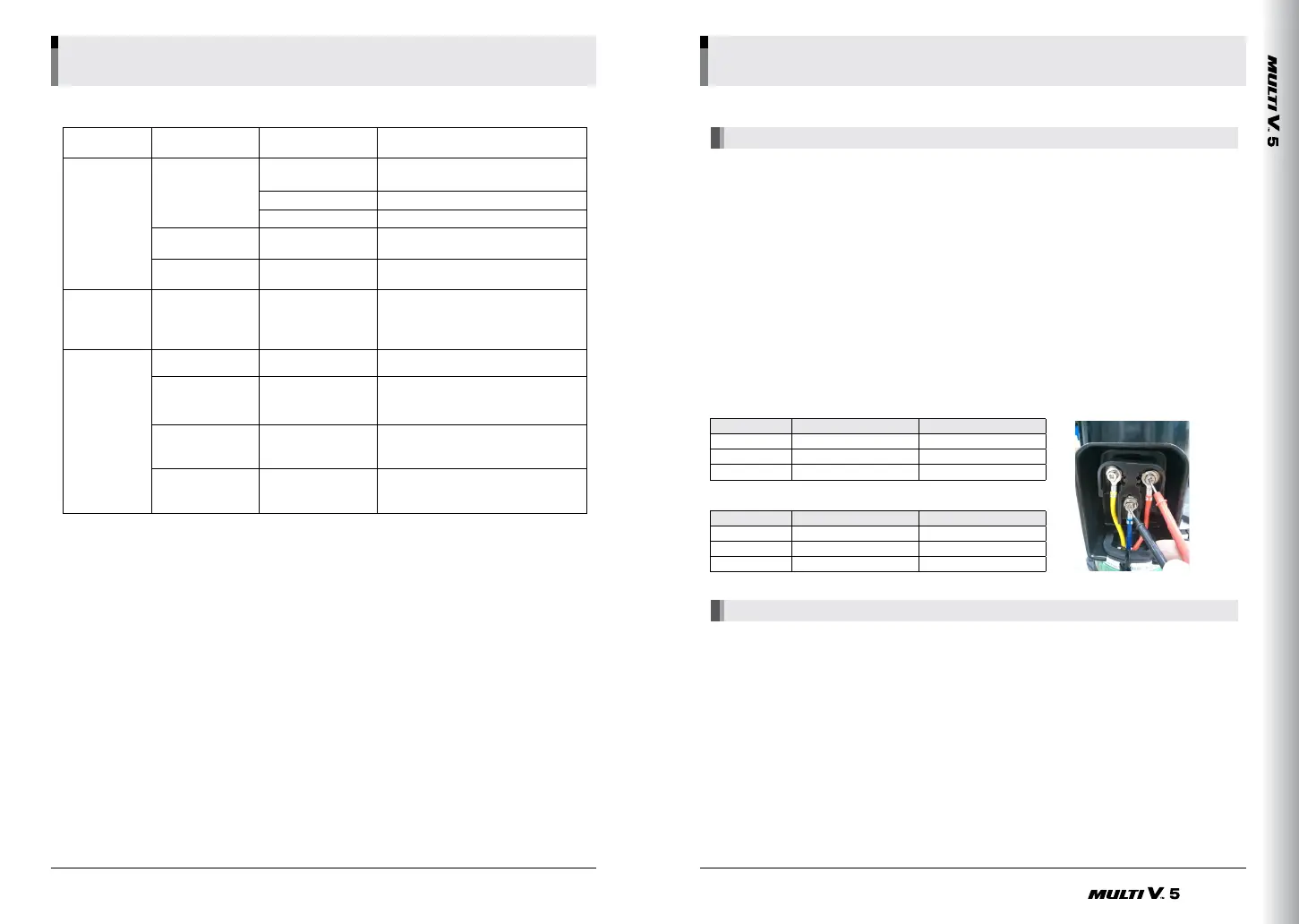

Compressor

Outdoor

fan

Outdoor

EEV

Not operating

Stop during running

Abnormal noise

during running

High pressure error

in cooling mode

operation

Heating failure, fre-

quent defrosting

No operation sound

after switching ON

the power supply

Heating failure,

frozen outdoor heat

exchanger part

Low pressure error

or discharge temper-

ature error

Motor insulation broken

Strainer clogged

Oil leakage

Motor insulation failure

R-S-T misconnection

Motor failure,

bad ventilation around

outdoor heat exchanger

Bad connector contact

Coil failure

EEV clogged

EEV clogged

Check resistance between terminals and

chassis

Change strainer

Check Oil level after opening oil port

Check resistance between terminals and

chassis

Check compressor R-S-T connection

Check the fan operation to confirm proper

motor functioning. Switch OFF the outdoor

unit and remove obstacles, if any, around

the HEX. Check connector

Check resistance between terminals

Service necessary

Service necessary

Component Phenomenon Cause Check method and Trouble shooting

The phenomena from main component failure

2.1 Failure Judge Method

2.2 Failure Cause

2. Compressor

1. Error display (CH21, CH22, CH26, CH29)

- Failure to restart after power reset

- Main power supply failure from inverter board to compressor

- Compressor input current is normal but compressor fails to start

with electric noise from inverter board

- CH29 in normal operation and cycle

2. Phase current , input current hunting

- The phase current, input current value is hunting more than 5A in

stable state of high / low pressure and compressor Hz

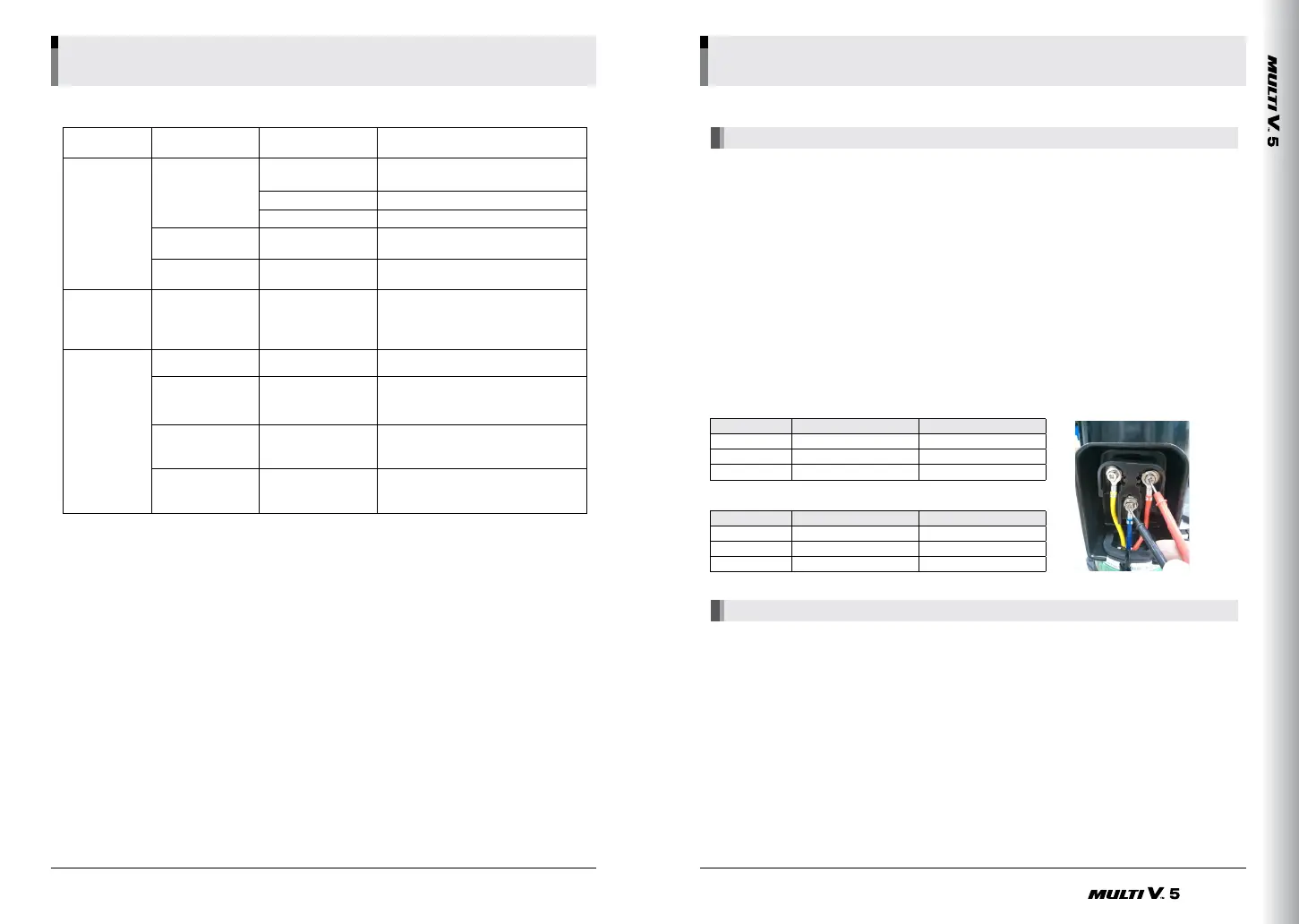

3. Coil resistance (U-V, V-W, W-U) and insulation resistance measurement

- Insulation resistance : 50MΩ or more

- Coil resistance : refer to below

· Failure to obtain discharge superheat (refrigerant overcharging)

· High discharge temperature (refrigerant shortage)

· Failure to obtain high and low pressure difference

· Defective compressor

· Foreign substance inflow

· Overload operation

· Nitrogen / Vapor inflow and poor vacuum

· Defective oil return valve

· Oil return piping blocked

· Defective VI EEV

· Defective oil balancing valve

· Oil shortage due to oil leakage

· Lack of oil due to frequent Thermo On / Off

LGE Internal Use Only

1-2. 압축기 불량 판단

CH21, CH22, CH26, CH29

• 전원 Reset 후 재기동 여부 확인

• 압축기에 Inv보드에서 전원 인가 확인.

• 압축기 기동시 인버터 보드에서 전자기음과 함께 압축기에 투입되는 전류가 상승함에도 압축기 기동 안함.(CH26)

• 정상 운전 중 cycle의 특이한 변화가 없는데도 CH29 발생

상전류/입력전류 헌팅

• 고/저압 및 압축기 Hz가 고정되어 있으나 상전류 or 입력전류 값이 ±5 A 이상으로 헌팅할 경우 압축기 손상 판단됨.

압축기 상간 저항 및 절연 저항 측정

JQC068MA

*

Temp. 25 ℃ 75 ℃

U-V 0.216 ± 7 % Ω 0.258 ± 7 % Ω

V-W 0.216 ± 7 % Ω 0.258 ± 7 % Ω

W-U 0.216 ± 7 % Ω 0.258 ± 7 % Ω

JQC048MA

*

Temp. 25 ℃ 75 ℃

U-V 0.302 ± 7 % Ω 0.360 ± 7 % Ω

V-W 0.302 ± 7 % Ω 0.360 ± 7 % Ω

W-U 0.302 ± 7 % Ω 0.360 ± 7 % Ω

Basic PartBasic PartBasic PartBasic Part

Loading...

Loading...