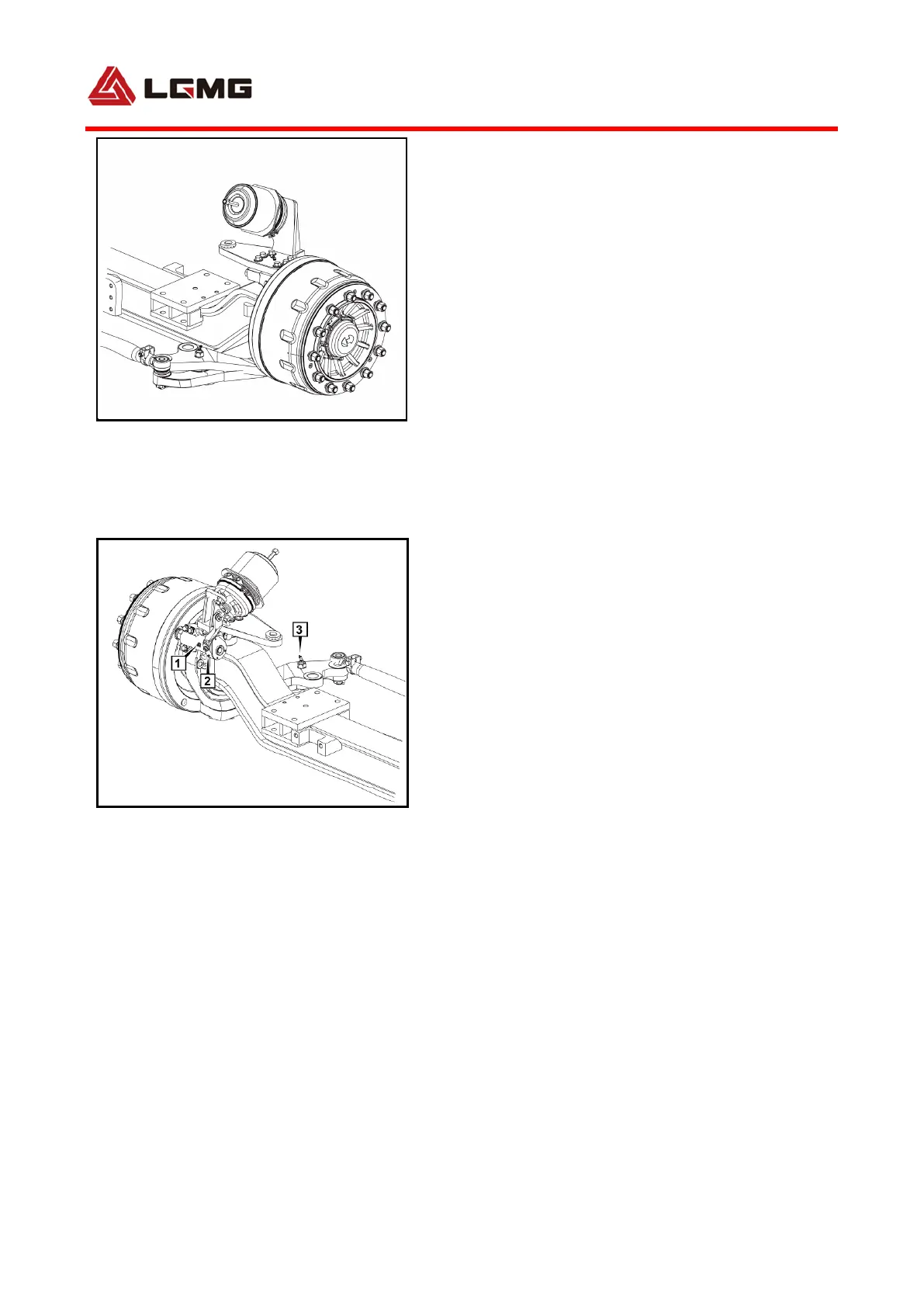

Fig. 4-21 Front Driving Axle

Check if connecting bolts between the tie

rod and tie rod arm are loose.

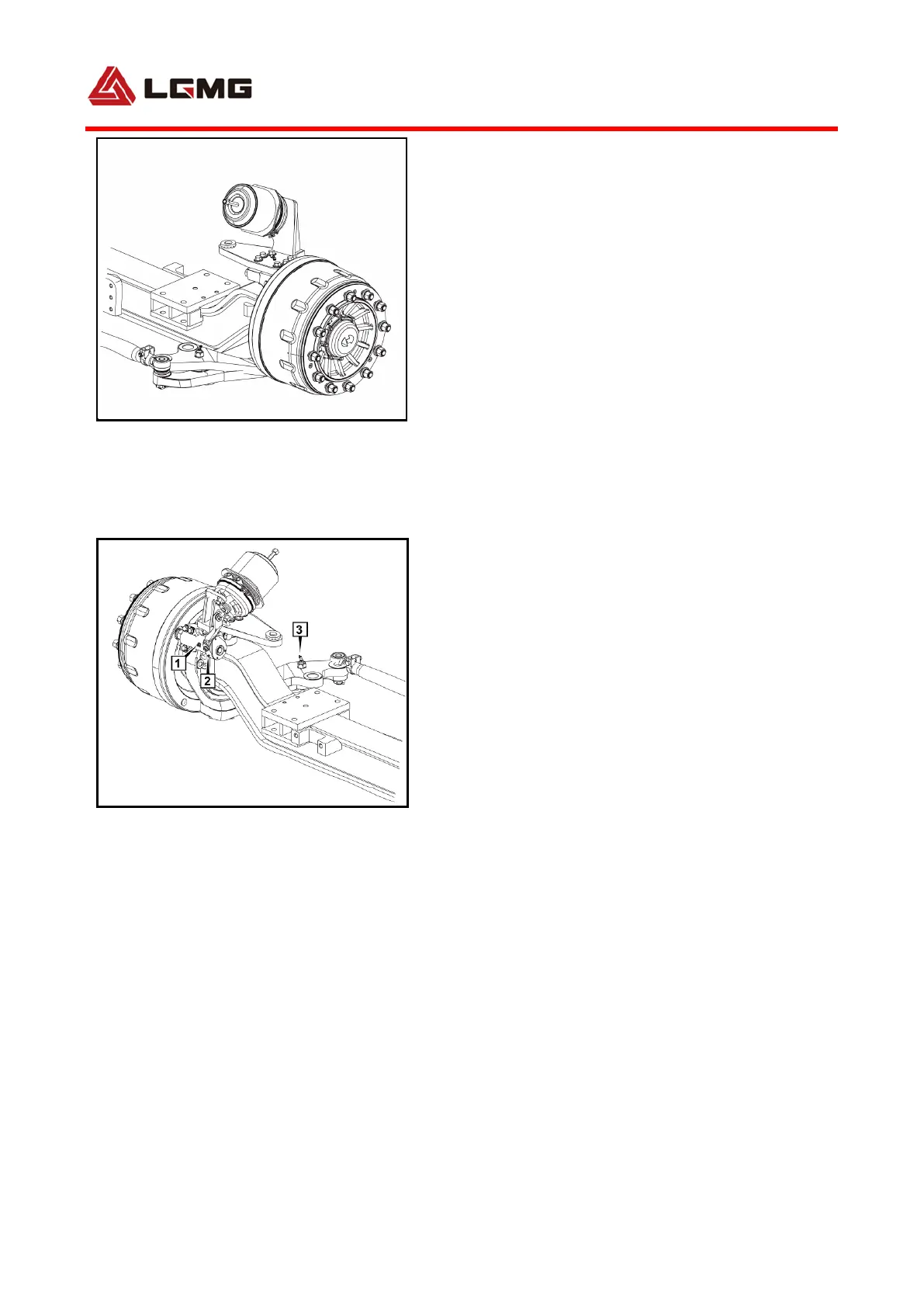

Fig.4-22 Front Driving Axle

1. Camshaft support grease nozzle 2.

Regulating arm grease nozzle

the rim, the outer circle surface between the rim positioning

hole and the wheel rim reduction shell, and the seal surface

of the wheel nut;

② Do not damage threads of the wheel bolts, and apply

grease, oil, or other thread paste to the threads of the wheel

bolts and wheel nuts before installation;

③ Tighten the wheel nuts diagonally and evenly, and after

each re-assembling of the tire, the tire nut must be

re-tightened after 50 km of travel.

d.Precautions for operation of brake shoe friction plate:

● When the vehicle has run for the first 5,000km, check the

thickness of the brake shoe friction plate, which shall not to

be less than 8mm. The inspection period thereafter may be

shortened as appropriate to avoid other serious faults due to

excessive wear of the friction plate;

● The clearance between the brake shoe and the brake drum

shall be kept between 0.7 and 1.2 mm, and the clearance

between the upper and lower drums and shoes shall not be

greater than 0.3 mm;

● The axle friction plate must be accessories from Lingong

Group Jinan Heavy Machinery Co., Ltd.

2) Maintenance of axle

a. Routine maintenance

① Check if the wheel nuts are loose and fasten them before

the truck running;

② Check the axle for oil leakage before the truck running;

repair it if any leakage;

③ Check the brake performance and brake return condition.

The brake clearance shall be between 0.7 and 1.2 mm. In

case of improper brake clearance or poor brake return, check

Loading...

Loading...