FlexPower DC Power System Installation Manual

14 15

User Certificate

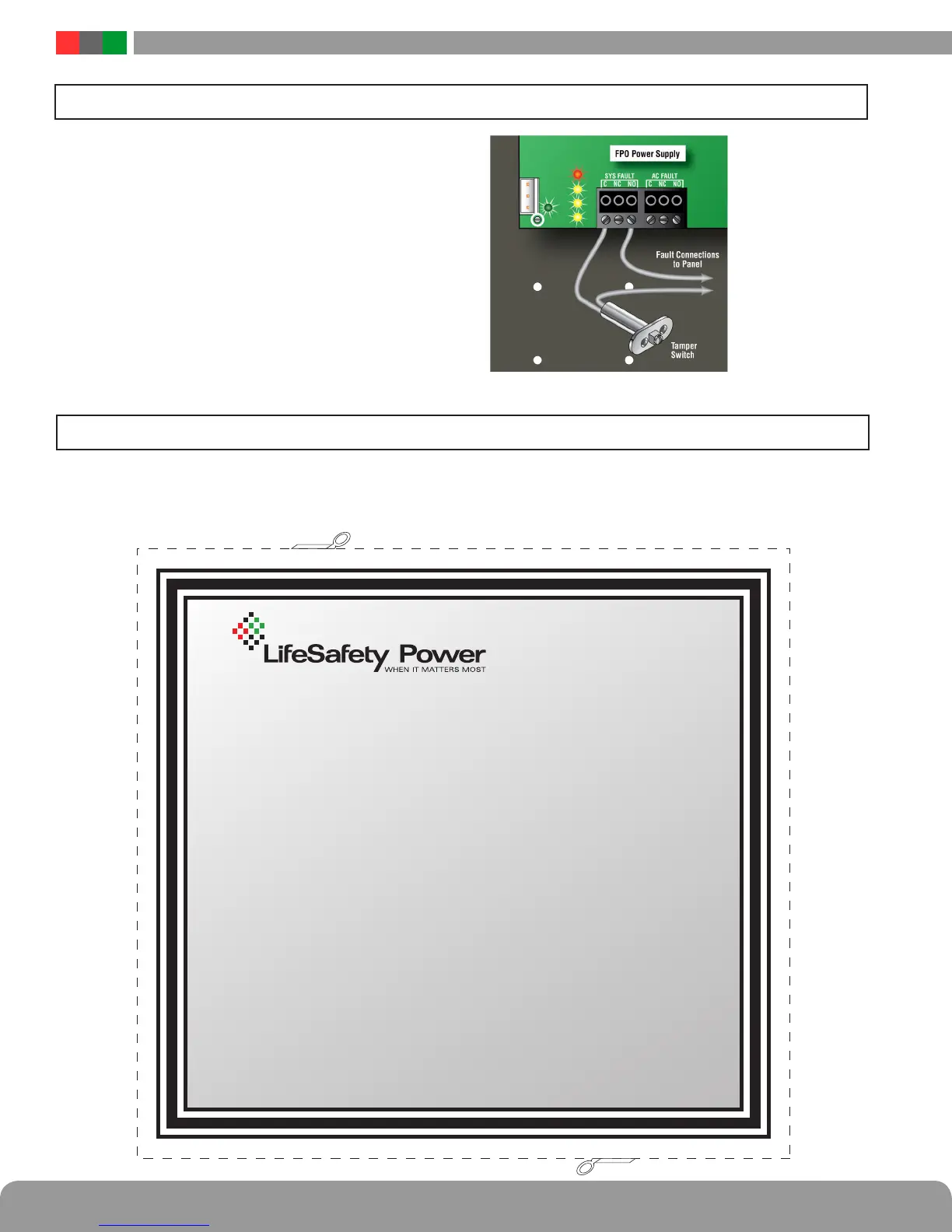

Appendix 1 – Tamper Switch Wiring

All FlexPower DC systems with an enclosure include a normally

closed tamper switch for monitoring by the host panel. The

tamper switch can either be brought into a dedicated input in

the panel (see the panel's instructions), to the Event 1 input of a

Netlink Network Module (See the Netlink's Instruction Manual),

or the tamper switch may be series connected into the System

Fault relay in the FPO supply as shown in the illustration.

Any UL1076 installation must use the tamper switch to indicate

the opening or removal of the front door of the enclosure.

Below is a certificate required for UL603 installations, to be cut out, framed and hung adjacent to the FlexPower

Power Supply system after installation. It contains the required battery information, as specified in UL603.

Specifications for the following model numbers:

FPO150 / FPO250

Maximum Charging Current: 2A

Maximum Battery Capacity: 80AH

Battery Type: Sealed Lead Acid or Gel Cell

Specifications for the following model numbers:

FPO75

Maximum Charging Current: 1A

Maximum Battery Capacity: 40AH

Battery Type: Sealed Lead Acid or Gel Cell

Appendix 2 – User Certificate

Loading...

Loading...