Page 79 of 192

• The mounting plate in the application must cover the entire top plate of the BL1 and be strong enough to carry the load.

• It is recommended that all 4 holes in the motor housing are used to fasten the BL4 to the application.

• The screws must provide a secure fixing e.g. as with self-locking.

• Remember to secure the cable to the housing with a cable tie. Use the fixing eye next to the connector socket.

On the BL4 cables, clip sleeve are mounted, they need to be removed.

• Electro Static Discharges!

Be aware that there is no electrical connection through the length of the BL4 column. Therefore, to avoid ESD issues, consider external

potential alignment between the top and bottom of the bed frame.

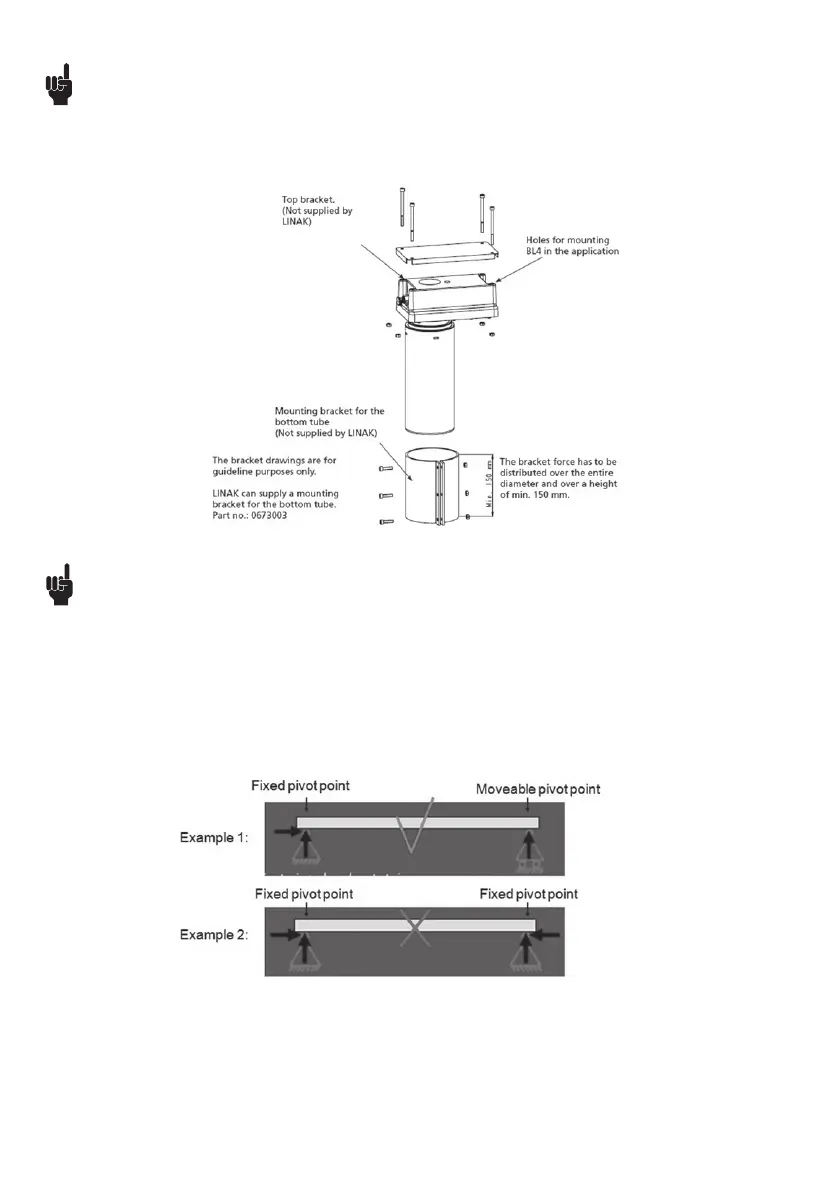

BL4 Mounting guidelines:

• The BL4 must always be mounted vertically before operation and always vertical with the motor housing uppermost.

(Otherwise, the internal end-stop switch system can break due to rotation).

• Both the motor housing and the bottom tube (the one with the largest diameter) must be secured in the application in such a way

that no rotation can occur.

• It is recommended to monitor the current consumption in order to determine the necessary tensioning force for the mounting bracket.

If the current consumption rises the BL4 has been tightened too much.

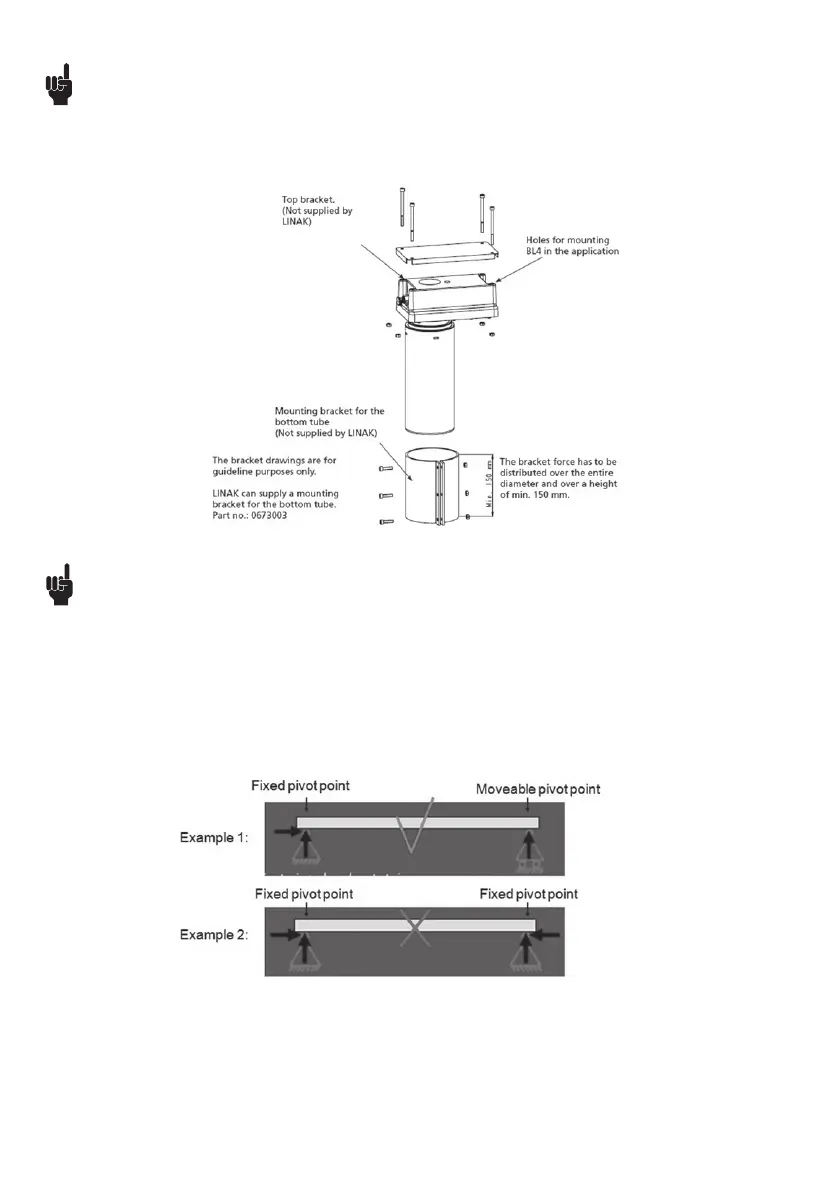

When mounting more than one BL4 you need to consider the fixation:

Loading...

Loading...