User Manual

Lubrigun Pumps 50:1

7.3A-38010-C05

Page 15 of 22

Subject to change

LINCOLN GmbH & Co. KG

∗

Postfach 1263

∗

D-69183 Walldorf

∗

Fax + (49) 6227 33259 ∗ Tel + (49) 6227 330

Lubrigun Pumps No. 82050, No. 82054, No. 83513, No.82050-E575, Ser. J

5.

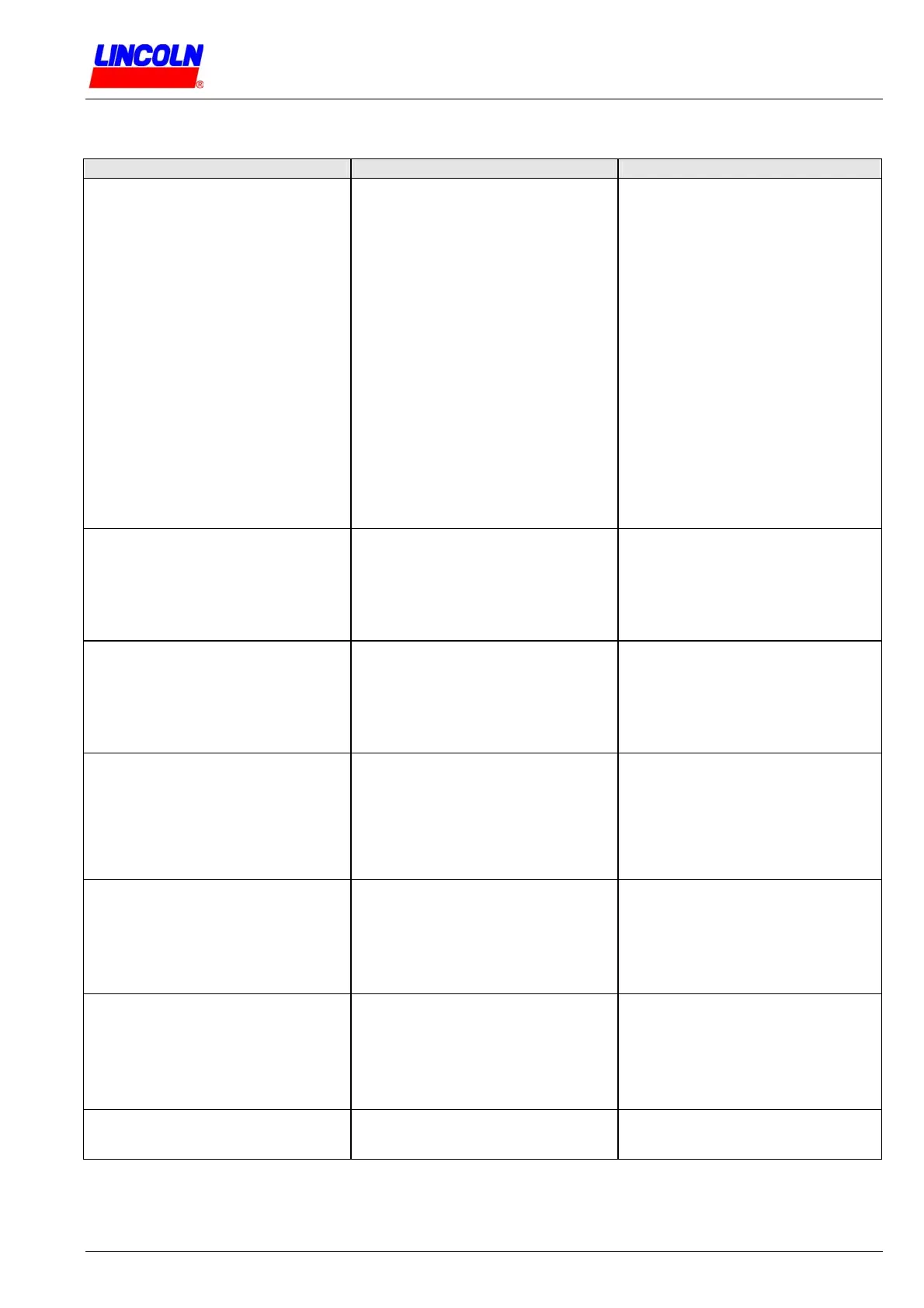

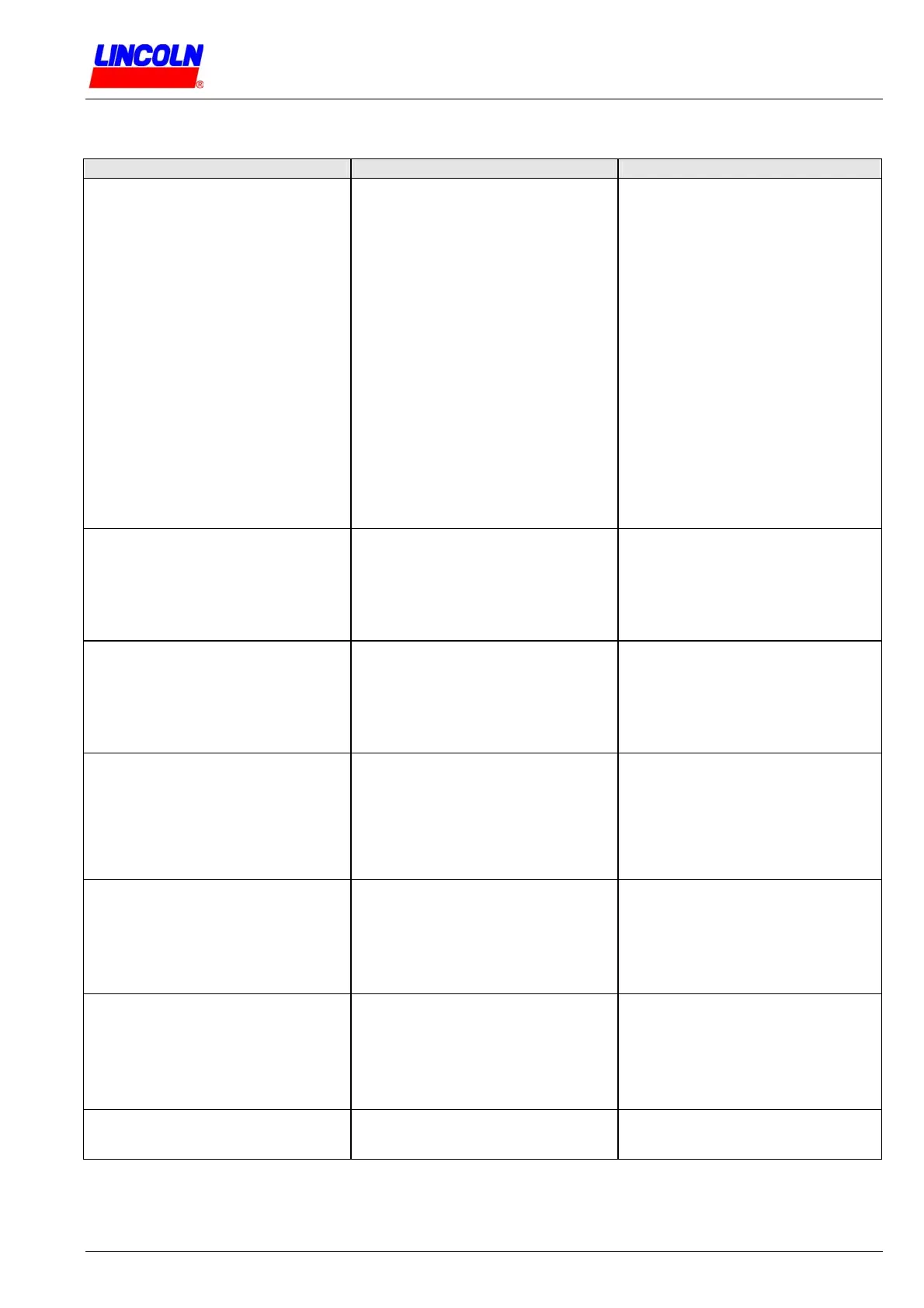

6 Troubleshooting - Check List -

Problem Possible Cause Solution

Pump does not operate. Airmotor does

not start operating.

Air supply is shut off.

Air supply is inadequate.

(Air pressure too low).

Trip Rod (16) broken

and/or

Toggle Plate (74) broken.

Foreign object clogging the pump tube.

Obstructed material output.

(For example the material control valve is

clogged)

Check if main air supply is shut off; if not,

check air connecting line to Pump for

breaks/disconnection of air supply and

clear air flow obstructions.

Cautiously increase air pressure to pump

by air pressure regulator if pressure too

low.

Shut off pump. Perform pressure relief

procedure. Check Airmotor. Dis-

assemble. Check parts and replace if

damaged.

Shut off pump. Perform pressure relief

procedure. Disassemble pump tube.

Clean and inspect check valves of pump

tube. Replace parts if damaged.

Shut off pump. Perform pressure relief

procedure. Disassemble and clean

material line components to remove

restrictions.

Air seepage from air exhaust while pump

is not operating.

Valve Slide & Seat (65) / Gasket (64) of

airmotor damaged.

Sealing (22 & 24) damaged. Seepage

between air cylinder and airmotor head.

Shut off pump. Perform pressure relief

procedure. Remove parts for inspection

and replace if damaged.

Shut off pump. Perform pressure relief

procedure. Disassemble airmotor and

replace parts.

Erratic or accelerated operation of the

pump. Pump cycles increase but material

output unchanged.

Material too ‘heavy’ or pump cycles too

fast for intake of material. Increase of

viscosity of the material caused for

example by temperature drop.

Insufficient material supply. Pump sucks

air because of low level of material.

Reduce air pressure to pump.

Heat material.

Shut off pump. Refill or change material

container.

Continuous operation of pump when not

in normal use (outlet / material control

valve closed)

Material container empty on continuous

acceleration of pump cycles.

Material supply line broken/leaking.

Inlet Check Valve (51 & 52 ) of pump

tube inlet damaged.

Shut off pump. Refill or change material

container.

Shut off pump. Check and tighten line.

Shut off pump. Perform pressure relief

procedure. Remove check valve and

inspect; replace if damaged.

Loss of pressure and volume. Pump does

not stop operating after material outlet is

closed.

Priming check seat (51 & 52) in lower

part of pump tube or check (43 & 46) seat

in plunger are worn.

Plunger rod (47) and packing (49) in

lower part of pump tube are damaged or

worn.

Shut off pump. Perform pressure relief

procedure. Disassemble pump tube and

replace worn check parts.

Shut off pump. Perform pressure relief

procedure. Disassemble pump tube and

check. Replace packing or damaged

plunger rod.

Material leaking from weep hole at

bottom of Outlet Casting (14).

Seals of gland in outlet casting are worn. Shut off pump. Perform pressure relief

procedure. Disassemble pump. Check if

Gland Nut (27) is tight.

Remove Gland Nut and parts. Replace

O-Ring (32), U-Cup Packing (33),

Packing (29) & Gasket (30). Check

Piston Rod (11) and replace if worn.

Excessive amount of air in material

(lubricant) or excessive amount of

lubricant coming from air exhaust.

Seals of gland in outlet casting are worn. Solution as described above

Note: All codes indicated in bold-type bracket ( ) refer to item numbers listed on service parts dwg. and service

parts list of the pump models.

Loading...

Loading...