User Manual

Lubrigun Pumps 50:1

7.3A-38010-C05

Page 16 of 22

Subject to change

LINCOLN GmbH & Co. KG

∗

Postfach 1263

∗

D-69183 Walldorf

∗

Fax + (49) 6227 33259 ∗ Tel + (49) 6227 330

6. Repair

Repairs must be carried out by skilled, trained

personnel only.

WARNING

Do not attempt to disassemble the

pump while airmotor, pump tube and

other equipment components are

pressurized.

Do not flush or clean pump/pump tube

with flammable fluids.

Hands away from lower part (material

inlet) of the pump while operating or

testing the pump.

• After shutting off the pump, before disassembling

always relieve drive (airmotor), pump tube and other

system components from pressure.

− Disconnect air coupler from the pump, allowing the

compressed air to exhaust completely from the

airmotor.

− Turn valve (Shut-off valve / flow gun) to position

‘open’ at end of the material line and drain the

dispensing material into a collecting can.

Warning: Dispensing material is pressurized.

Always use a container for collecting drained material.

− Shut material valve off when material line is

depressurized and material stops bleeding.

− After pressure relief procedure is completed,

cautiously loosen connector of material supply line at

pump outlet; remove material line (connecting hose)

from pump.

6.1 Tools required

Hex keys and Hex. wrenches with inch-measures are

required. Furthermore pliers, screw drivers and other

standard tools of a workshop are required for the

disassembly of the pump.

6.

2 Disassembly instructions

The disassembly instructions are designated for service

personnel only with special knowledge and experience

of hydraulic and pneumatic equipment.

Attention: Never make any modifications! Use original

spare parts only. See service parts list.

Collect dispensing material. Ensure that all con-

sumables are disposed of safely according to the

regulations of the authorities after repair.

Note: All codes indicated in bold-type bracket ( ) refer to

item numbers listed on service parts dwg. and service

parts list.

Adhere to stated torque specifications on re-assembly:

(21) Valve cover screw

1/2“ hex. hd 10,5-11 Nm

(25) Trip rod packing nut

3/4“ hex. hd. 13,6-20,3 Nm

(57) Hex. socket screw

5/32“ hex. 3,4-4,4 Nm

(71) Hex. socket screw

5/32“ hex. 3,4-4,4 Nm

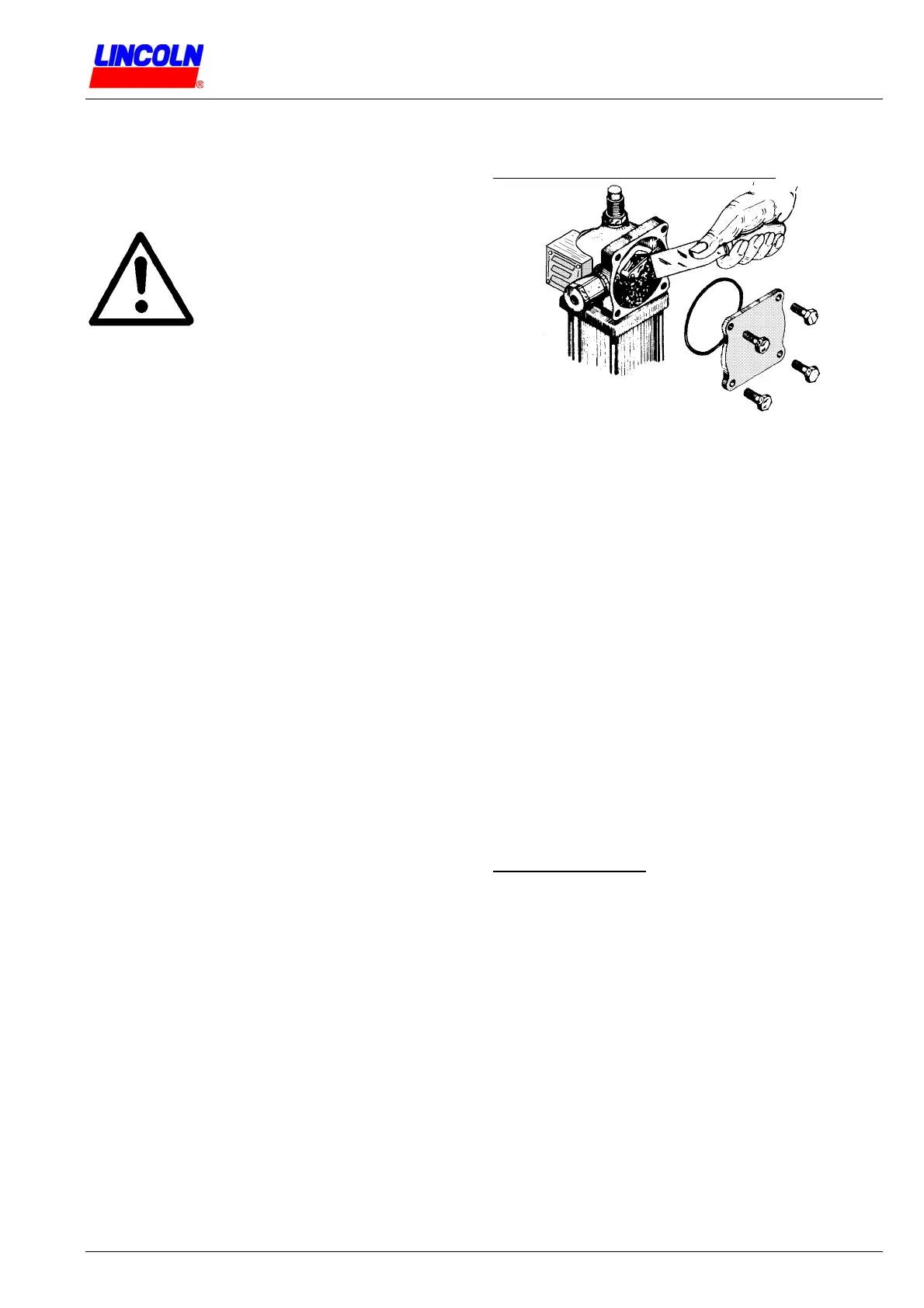

Maintenance of the Air Valve Mechanism

Greasing of air valve mechanism

Lubricate air valve mechanism located inside of the Air

Valve Casting (4) at least once a year with grease.

Use ~ 45 cm

3

N.L.G.I. No. 1 (light grade) water repellent

grease for lubrication. Replace O-Ring (20).

a) Disconnect air coupler from the pump. Turn valve to

position ‘open’ at end of the material line and drain

the material into a collecting can.

b) After pressure relief procedure is completed, remove

the four Valve Cover Screws (21), Cover (72) and

O-Ring (20) from Air Valve Casting of the airmotor.

c) Remove old grease. Wear safety glasses! Use air

blow gun to remove any chips or foreign particles.

d) Use spatula, as illustrated, to pack also cavity behind

the Toggle Plate with grease.

e) Check if O-Ring is correctly seated before re-

assembling the Cover.

f) Fasten the four 1/2“ hex. head Screws (21) of the

Cover with torque of 10,5-11 Nm.

Remark: On repair/overhaul and disassembly of the

airmotor head (disassembly of pump and pump parts),

carefully clean parts including the air valve casting

before re-assembly and greasing.

Disassembly of pump.

After pressure relief procedure is performed and pump

is removed for service, clamp pump by a vise at outlet

body.

1. Remove Valve Cap (1) from Air Valve Casting (4);

remove Valve Cap Gasket (3).

2. Remove Trip Rod Pin (2) and Trip Rod Collar (19).

3. Unscrew Tie Rod Nuts (75) from the four Tie

Rods (63).

4. Lift Air Valve Casting (4) manually a little off from Air

Cylinder (13) until Trip Rod is exposed and

cautiously grip (do not damage rod) Trip Rod (16) in

front of the Trip Rod Packing Nut (25); unscrew Trip

Sleeve (5) from end of the Trip Rod (16).

Lubrigun Pumps No. 82050, No. 82054, No. 83513, No. 82050-E575, Ser. J

Loading...

Loading...