User Manual

Lubrigun Pumps 50:1

7.3A-38010-C05

Page 6 of 22

Subject to change

LINCOLN GmbH & Co. KG

∗

Postfach 1263

∗

D-69183 Walldorf

∗

Fax + (49) 6227 33259 ∗ Tel + (49) 6227 330

3. Specifications of the Product

LUBRIGUN PUMPS

Model No. 82050, No. 82054, No. 83513,

No. 82050-E575

piston pump, air operated

pressure ratio 50:1.

Manufacturer

Sales & Service

LINCOLN Lincoln GmbH & Co. KG

St. Louis, Mo 63120-1578 Heinrich-Hertz-Str. 2-8

USA D-69190 Walldorf

Contacts for inquiries and service:

⇒ See telephone- and Telefax number below

3.

1 Designated Use

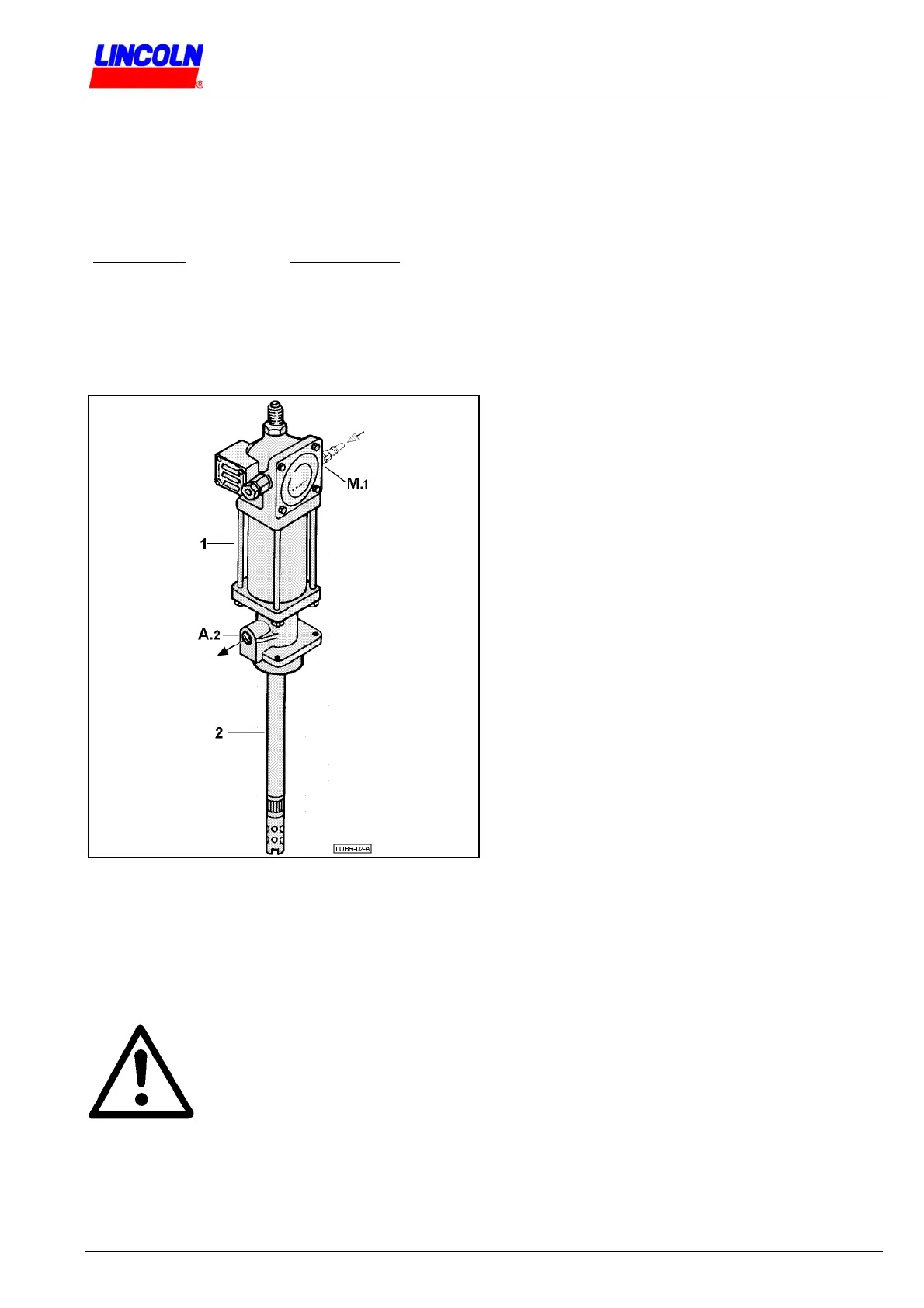

Lubrigun Pump

M.1

Air inlet

A.

2

Material outlet

1

Pump drive (airmotor)

2

Pump tube (piston pump)

Pump drive & Pump tube are one unity.

Air quick-coupling for connecting pump drive not in-

cluded in scope of supply.

Warning

Do not operate pump drive (airmotor)

with combustible gas.

Always use compressed air only to operate airmotor of

the pump.

LINCOLN Lubrigun Pumps are built in accordance with

state-of-the-art standards and the recognized safety

rules. Nevertheless, its use may constitute a risk to life

and limb of the user or third parties, or cause damage to

the equipment and to other material property.

Lubrigun Pumps, models with pressure ratio 50 : 1, are

designed for pumping petroleum based lubricants;

preferable for semi-fluid grease and common chassis

grease not exceeding NLGI #2.

Using the equipment for purposes other than those

mentioned above is considered contrary to its

designated use. The manufacturer/supplier cannot be

held liable for any damage resulting from such use. The

risk of such misuse lies entirely with the user.

Operating the equipment within the limits of its

designated use also involves observing the instructions

set out in the operating manual and complying with the

inspection and maintenance directives.

Commissioning and operating the equipment are

permitted in the European Community only when the

machine/machinery, which the Pump is intended to be

used on, is in conformity with safety requirement

according to EC directives for safety of machinery.

Contact LINCOLN prior to using the Pump in case of

any questions regarding the appropriate use of the

equipment. Refer to bottom line for postal address,

phone and fax number.

Note

In case of pumping semi-fluid, non-fluid lubricants, the

user has to take steps to allow the pump to take in the

material to be pumped, for example by attaching a

follower plate or by heating the material. Among other

things, the pumpability of the material depends on the

environmental conditions of the individual application.

An air pressure regulator is required by the user to

adjust pump cycles and pressure to pump.

System components to operate the Pump individually

depend on the specific requirement. Ask for assistance

if required.

Loading...

Loading...