User Manual

Lubrigun Pumps 50:1

7.3A-38010-C05

Page 7 of 22

Subject to change

LINCOLN GmbH & Co. KG

∗

Postfach 1263

∗

D-69183 Walldorf

∗

Fax + (49) 6227 33259 ∗ Tel + (49) 6227 330

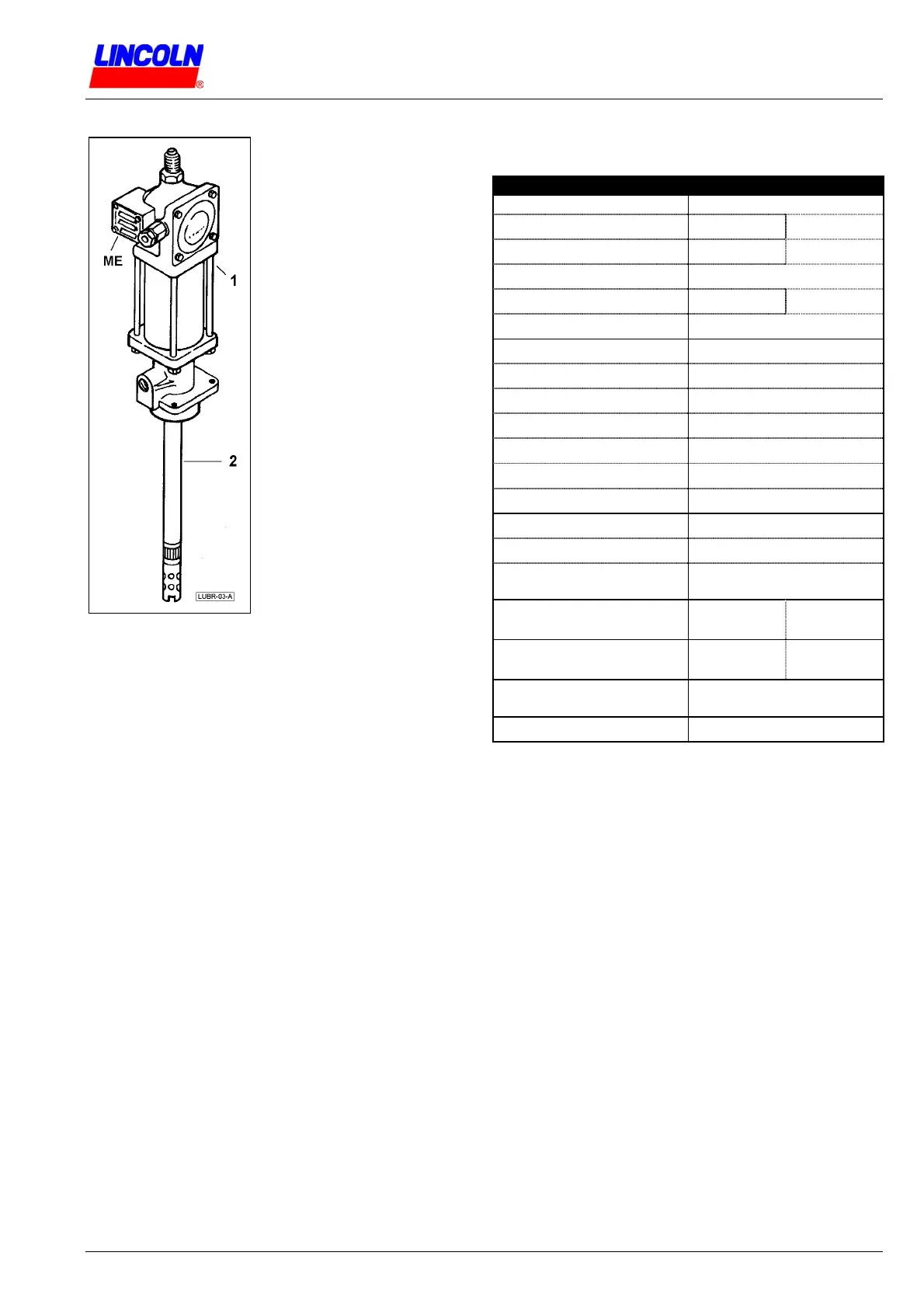

3.2 General Description

Pump Models:

No. 82050, No. 82054,

No. 83513, No. 82050-E575.

Pump models listed above are

of same technical design. The

models differ by length of the

pump tube (2) only.

1

Pump drive

(airmotor)

2

Pump tube

(piston pump)

ME

Air exhaust

(muffler)

1 & 2 are one unity.

Lubrigun Pump

Lubrigun Pumps 50:1

are air operated, double acting pumps with differential

piston.

The pump discharges the material on “up“ and “down“

stroke to the outlet; material intake on “up“ stroke.

The pump transforms the incoming air pressure in a

50-times higher material delivery pressure.

The pump has a shovel-type foot valve. The shovel

supports the intake of the material to be pumped by

mechanical force; recommended application for

pumping chassis grease.

For pumping fluid and flowable lubricants, this pump

type can be optionally equipped with ball-type Foot

Valve No. 61275-E.

The pump tube is equipped with a precisely fitted piston

for appropriate use which is the pumping of lubricants.

The non-adherence of the designated use, for example

pumping of materials not having lubricating properties

may cause premature wear and damage to the bushing

& plunger assembly of the pump tube.

Accessories

depend on specific requirement. Ask for quotation in

case of requirement.

Air pressure regulator required for pump drive. Use 1/4“

(DN6) FRL-Air service unit (Filter, regulator, gauge,

lubricator) if compressed air is not free from foreign

particles and moisture.

3.3 Technical Data

Technical Data of Lubrigun pump models listed in

section 3.2:

Technical Data of Pump

Pump Dri v e : Airmotor

Stroke length 63,5 mm 2½“

Air cylinder-Ø 63,5 mm 2½“

Air consumption at 7 bar 4,2 l

(N)

/cycle

Air pressure )

1

min. 2,1 bar max. 10 bar

Air inlet ¼“ NPTF female

Pump Differential plunger pump

Pressure ratio i = 50 : 1

Max. output pressure )

2

500 bar at pump outlet

Discharge volume 5,7 cm

3

/cycle

Delivery output Q

g

0,43 l/min at 75 cycles

Max. pump cycles )

3

120 cycles/minute

Material outlet ¼“ NPTF female

Pump tube

Tube length see 3.4 ‘Dimensions’

Wetted part materials

Soft part seals:

Steel, Ms, Cu, PA,

NBR & Polyurethane

(Materials of pump)

Environmental temperature

TMIN

- 34° C

TMAX

+ 93° C

(Material to be pumped)

Operating temperature )

4

TAMIN

(see remark)

TAMAX

+ 60° C

Noise level

at 8 bar air operating pressure

< 85 dB(A)

Weight see 3.4 ‘Dimensions’

Underline: Cycle = “up“ and “down“ stroke of the pump.

Remarks

)

1

For operating pump with lower air pressure

(< 2,1 bar), attach Spring No. 55231 and Screw

No. 12834 to air valve mechanism of the airmotor.

)

2

Max. delivery pressure at 10 bar air pressure.

Limit air pressure not to exceed the max. working

pressure of the pump. When using system components

that are rated at lower working pressure than this pump,

then take pump pressure ratio of 50:1 into account;

reduce and limit air pressure to pump accordingly.

)

3

Do not exceed 75 cycles/min for continuous

operation. The pump cycles which can be achieved at

normal operation may be less than indicated and

depend on the material to be pumped and other

parameters.

Control pressure and pump cycles using an air pressure

regulator (by user). Always use the lowest pressure

required to achieve the desired results. Higher

pressures may cause pump packings to wear

prematurely.

)

4

The temperature of the material to be pumped must

be in a range that allows the material intake by the

pump and shall not restrict the pumpability of the

material.

Loading...

Loading...