LTC2983

57

2983fc

For more information www.linear.com/LTC2983

SUPPLEMENTAL INFORMATION

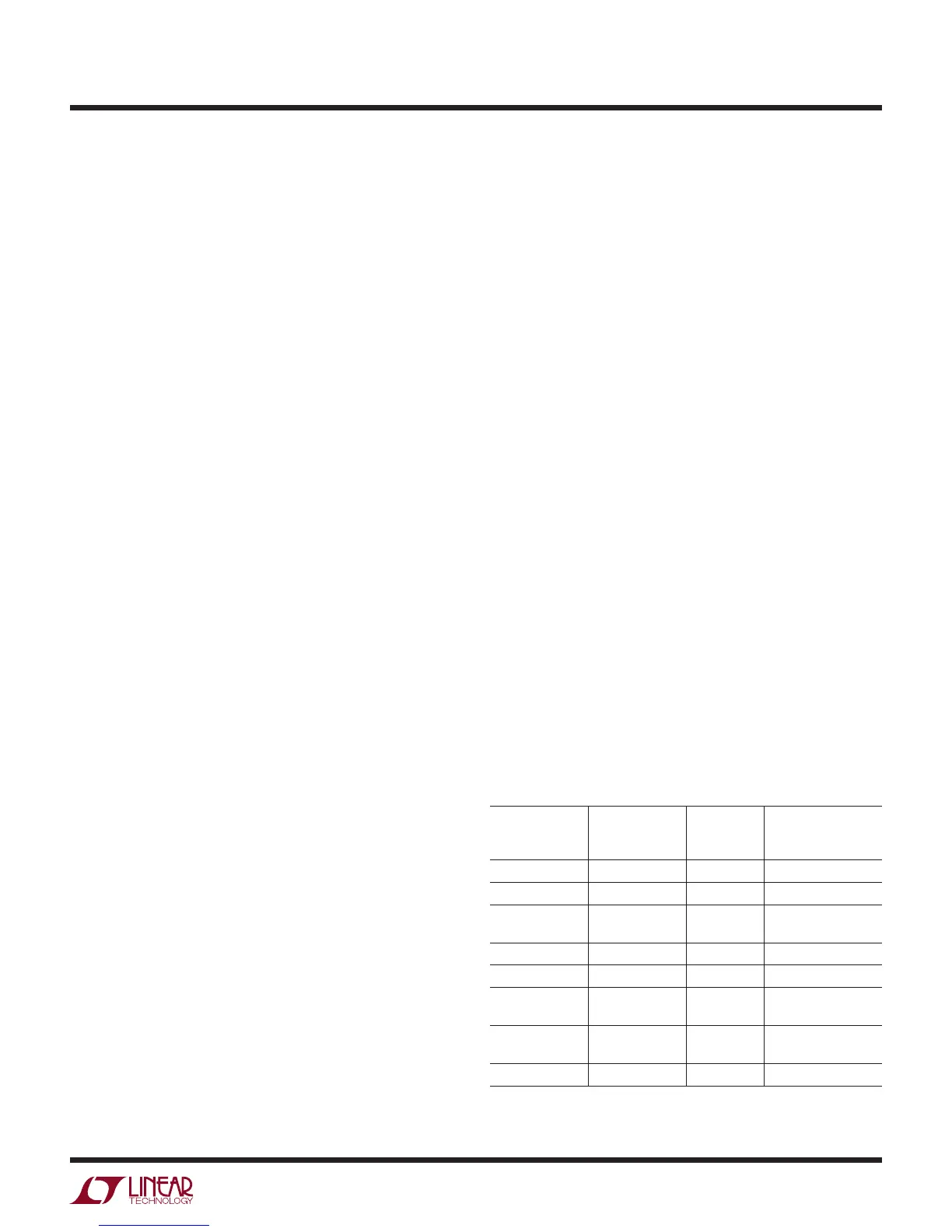

Table 64. 2- and 3-Cycles Conversion Modes

TYPE OF SENSOR CONFIGURATION NUMBER OF

CONVERSION

CYCLES

MAXIMUM OUTPUT

TIME

Thermocouple OC = 0 2 167.2ms

RTD All 2 167.2ms

Thermistor Non-Autorange

Current

2 167.2ms

Diode Two Readings 2 167.2ms

Thermocouple OC = 1 3 251ms

Thermocouple OC = 0, 3-Cycle

Cold Junction

3 251ms

Thermistor Autorange

Current

3 251ms

Diode Three Readings 3 251ms

Fault Protection and Anti-Aliasing

The LTC2983 analog input channels draw a maximum

of 1nA DC. As a result, it is possible to add anti-aliasing

and fault protection circuitry directly to the input of the

LTC2983. The most common input circuitry is a low pass

filter with 1k to 10k resistance (limited by excitation current

for RTDs and thermistors) and a capacitor with 100pF-0.1µf

capacitance. This circuit can be placed directly between

the thermocouples and 4-wire RTDs and the LTC2983.

In the case of 3-wire RTDs, mismatch errors between

the protection resistors can degrade the performance.

Thermistors requiring input projection should be tied to

the LTC2983 through a Kelvin type connection in order to

avoid errors due to the fault protection resistors.

2- and 3-Cycle Conversion Modes

The LTC2983 performs multiple internal conversions in

order to determine the sensor temperature. Normally, two

internal conversion cycles are required for each tempera-

ture result providing a maximum output time of 167.2ms.

The LTC2983 uses these two cycles to automatically

remove offset/offset drift errors, reduce 1/f noise, auto-

calibrate matched internal current sources, and provide

simultaneous 50/60Hz noise rejection.

In addition to performing two conversion cycles per result,

the LTC2983 also offers several unique features by utilizing

a 3rd conversion cycle. In this case, the maximum output

time is 251ms and all the benefits of the 2-cycle modes

are present (see Table 64).

One feature utilizing the three conversion cycle mode is the

internal open circuit detect mode. Typically, thermocouple

open circuit detection is performed by adding a high re-

sistance pull-up between the thermocouple and V

DD

. This

method can be used with the LTC2983 while operating

in the two conversion cycle mode (OC=0). This external

pull-up can interact with the input protection circuitry and

lead to temperature measurement errors and increased

noise. These problems are eliminated by selecting the

internal open circuit detection mode (OC=1). In this case,

a current is pulsed for 8ms and allowed to settle during

one conversion cycle. This is followed by the normal two

conversion cycle measurement of the thermocouple. If

the thermocouple is broken, the current pulse will result

in an open circuit fault.

A second feature taking advantage of the 3rd conversion

cycle is thermistor excitation current auto ranging. Since

a thermistor’s resistance varies many orders of magni-

tude, the performance in the low resistance regions are

compromised by the small currents required by the high

resistance regions of operation. The auto ranging mode

applies a test current during the first conversion cycle in

order to determine the optimum current for the resistance

state of the thermistor. It then uses that current to perform

the thermistor measurement using the normal 2-cycle

measurement. If a 3-cycle thermistor measurement is used

as the cold junction sensor for a 2-cycle thermocouple

measurement, the thermocouple conversion result is

ready after three cycles.

A third feature requiring a 3rd conversion cycle is the

three current diode measurement. In this mode, three

ratioed currents are applied to the external diode in order

to cancel parasitic lead resistance effects. This is useful

in applications where the diode is remotely located and

significant, unknown parasitic lead resistance requires

cancellation. If a 3-cycle diode or thermistor measure-

ment is used as the cold junction sensor for a 2-cycle

thermocouple measurement, the thermocouple conversion

result is ready after three cycles.

Loading...

Loading...