LTC2983

62

2983fc

For more information www.linear.com/LTC2983

In addition to digitizing standard RTDs, the LTC2983

can also digitize custom RTDs (RTD type=0b10010, see

Table26). Custom sensor data (minimum of three, maxi-

mum of 64 pairs) reside sequentially in memory and are

arranged in blocks of six bytes of monotonically increasing

tabular data Ω vs temperature (see Table 72).

Table 72. Custom RTD/Thermistor Tabular Data Format

ADDRESS BYTE 0 BYTE 1 BYTE 2 BYTE 3 BYTE 4 BYTE 5

0x250 + 6* Start Address Table Entry #1 (Ω) Table Entry #1 (Kelvin)

0x250 + 6* Start Address + 6 Table Entry #2 (Ω) Table Entry #2 (Kelvin)

0x250 + 6* Start Address + 12 Table Entry #3 (Ω) Table Entry #3 (Kelvin)

• • •

• • •

• • •

Max Address = 0x3CA Table Entry #64 (Ω) Table Entry #64 (Kelvin)

CUSTOM RTDS

Custom RTD Example

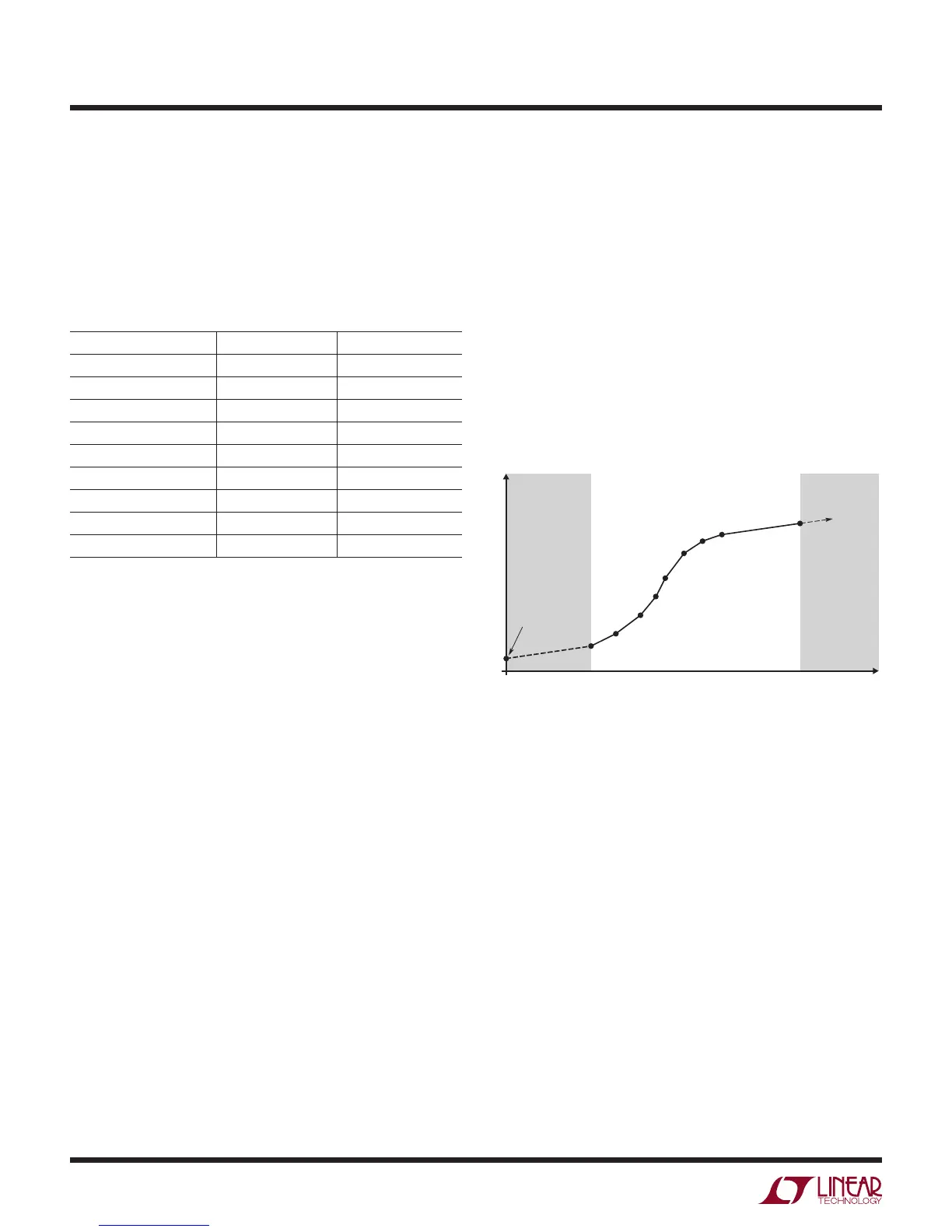

In this example, a simplified RTD curve is implemented (see

Figure 39). Points P1 to P9 represent the normal operating

range of the custom RTD. Resistance readings above point

P9 result in a soft fault and the reported temperature is

a linear extrapolation using a slope determined by points

P8 and P9 (the final two table entries). Resistance read-

ings below point P1 are also reported as soft faults. The

temperature reported is the extrapolation between point

P1 and P0, where P0 is the sensor output temperature

at 0Ω (This point should be 0Ω for proper interpolation

below point p1).

Figure 39. Custom RTD Example (Ω vs Kelvin )

2983 F39

p9

p8

p7

p6

p5

p4

p3

NOTE:

P0 SHOULD BE THE

EXTRAPOLATION

POINT TO 0Ω

RESISTANCE (Ω)

TEMPERATURE (K)

p2

p1

0

0

p0

RESISTANCE < p1

SOFT FAULT

CONDITION

RESISTANCE > p9

SOFT FAULT

CONDITION

Loading...

Loading...