Rev: 09.11.20 Page 5 CCD-0001360-AU

Assembling the Awning

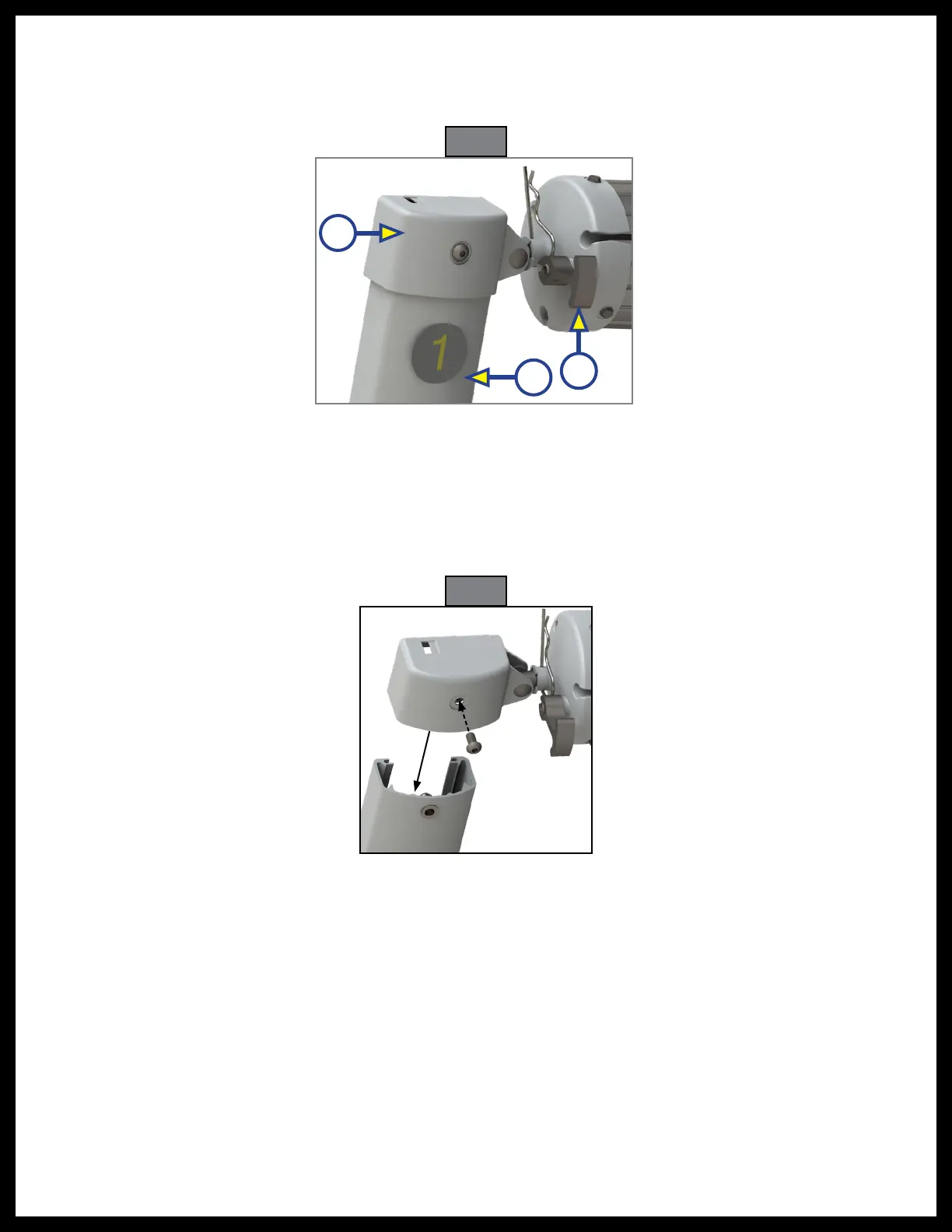

Note: The head assemblies (Fig. 3A) and support arm assemblies (Fig. 3B) are numbered to ensure proper

assembly. Match the proper support arm assembly to the correct head assembly.

Fig. 4

Fig. 3

B

C

1. On a flat surface, carefully lay out the support arm assemblies and roll tube assembly. The cam lock

(Fig. 3C) MUST be on the left end of the roll tube when facing the unit.

Note: Take care not to set the awning on any surface that may damage the assembly or fabric.

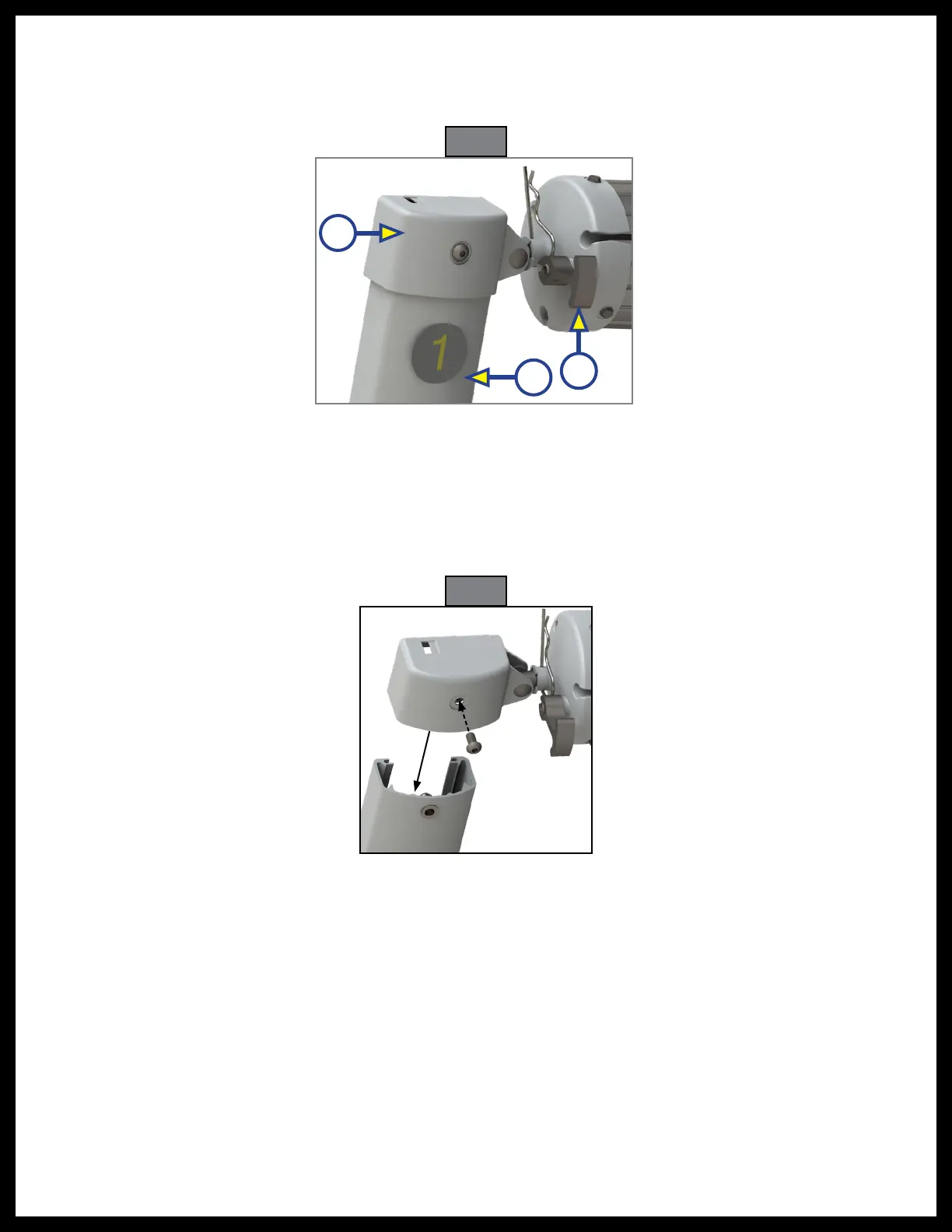

2. Slide the right support arm assembly into the idler head assembly of the roll tube. Align the holes and

secure using one

¼

-20 x

½

” Phillips drive screw.

3. Repeat step 2 for the left support arm assembly (Fig 4).

A

4. Measure and confirm the width of the awning. The distance is measured from centerline of support

arm assembly to centerline of support arm assembly (Fig. 2).

Mounting the Bottom Mounting Brackets

1. On the awning rail, mark position of the centerlines of support arm assemblies. Ensure that support

arm assemblies will not interfere with any lights, vents or the operation of any windows or doors.

2. Using a non-permanent method of marking, mark a perpendicular line from the awning rail down to

the floor line. This is the centerline of the support arm assembly (Fig. 2). Do this for both assemblies.

3. Position the bottom bracket with the fastening points at the floor line (Fig. 5A).

A. Center the bracket on the centerline mark of the support arm assembly (Fig. 5B).

B. Mark the hole locations, then using a

⁄

” drill bit, pre-drill both holes.

C. Apply a liberal amount of sealant over the holes.

Loading...

Loading...