TP0003B

BM METER

Chap 2

Page 4

TECHNICAL DESCRIPTION

Products suitable for use with FLUOROCARBON SEALS

Motor spirit

Aviation gasolines (ie. AVGAS)

Kerosene (with additives)

4.2

The above is only a guide and may not be accurate in every case, especially where extreme

temperatures are concerned. If in any doubt about seal selection, please contact our Engineering

Department at Liquid Controls.

5 ROTOR ASSEMBLY

5.1 The rotor assembly comprises an aluminium or NI-resist cast iron rotor secured by screws to

stainless steel stub axles running in bearings mounted in the inner covers. The output spindle is

located into the front stub axle and secured by a taper pin.

5.2 Slots in the rotor accept two pairs of horizontally opposed carbon vanes set at 90 degrees to each

other and mounted on rigid stainless steel rods. The rods are sealed with special glands where they

pass through the rotor.

5.3 In operation, liquid enters the meter through the inlet manifold and causes the rotor to revolve by

pressure on the vanes. The proximity of the rotor to the casing forms an efficient seal, whilst the

profile of the casing ensures that the vanes are guided through the metering crescent, where the

volume of product is accurately measured. Product at line pressure fills the spaces between the

inner and outer end covers providing pressure balanced inner end covers free from distortion. The

rotor motion is transmitted through an output spindle (which passes through a pressure tight seal in

the outer front cover) to the calibrating mechanism which, in turn, drives the mechanical counter.

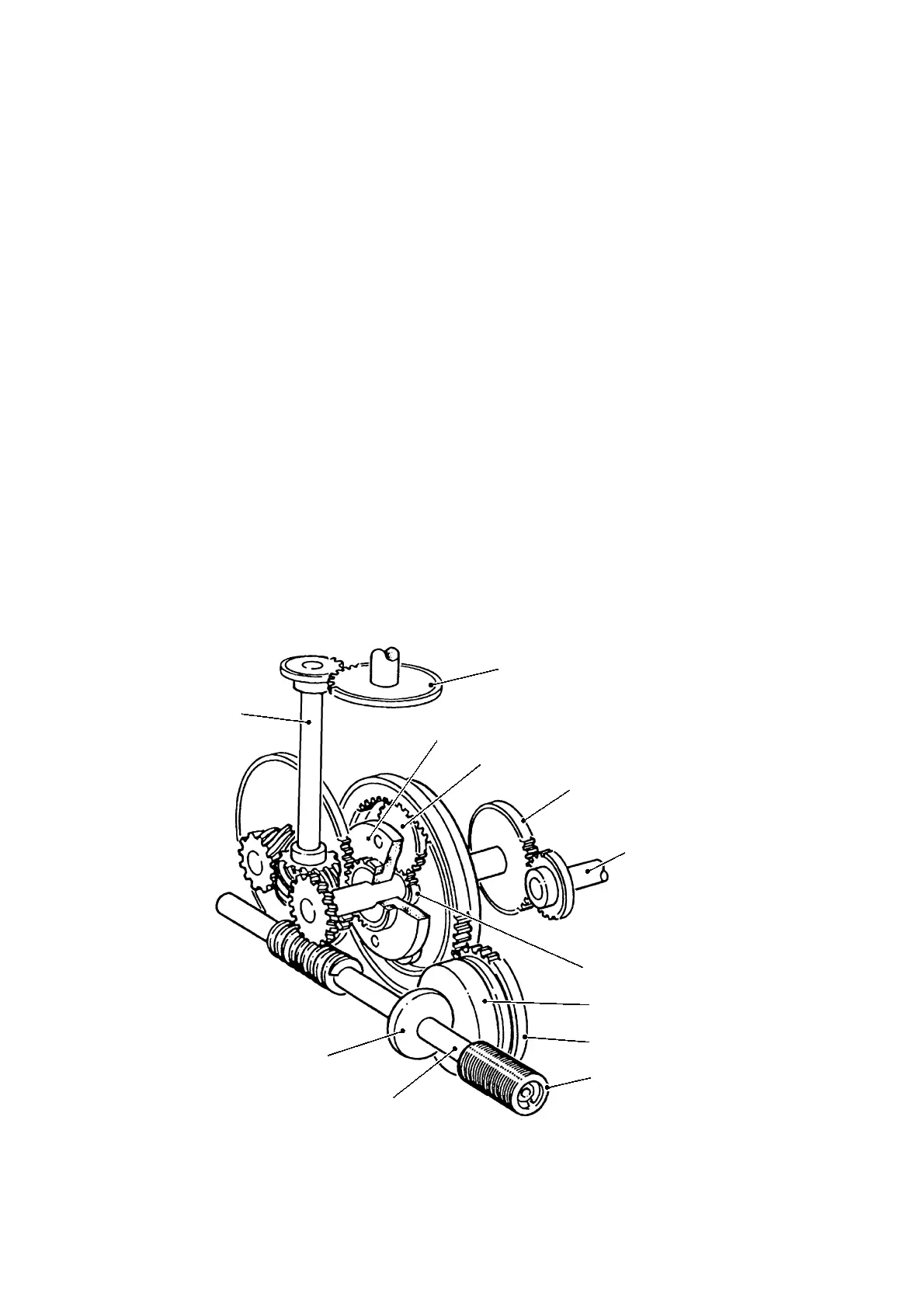

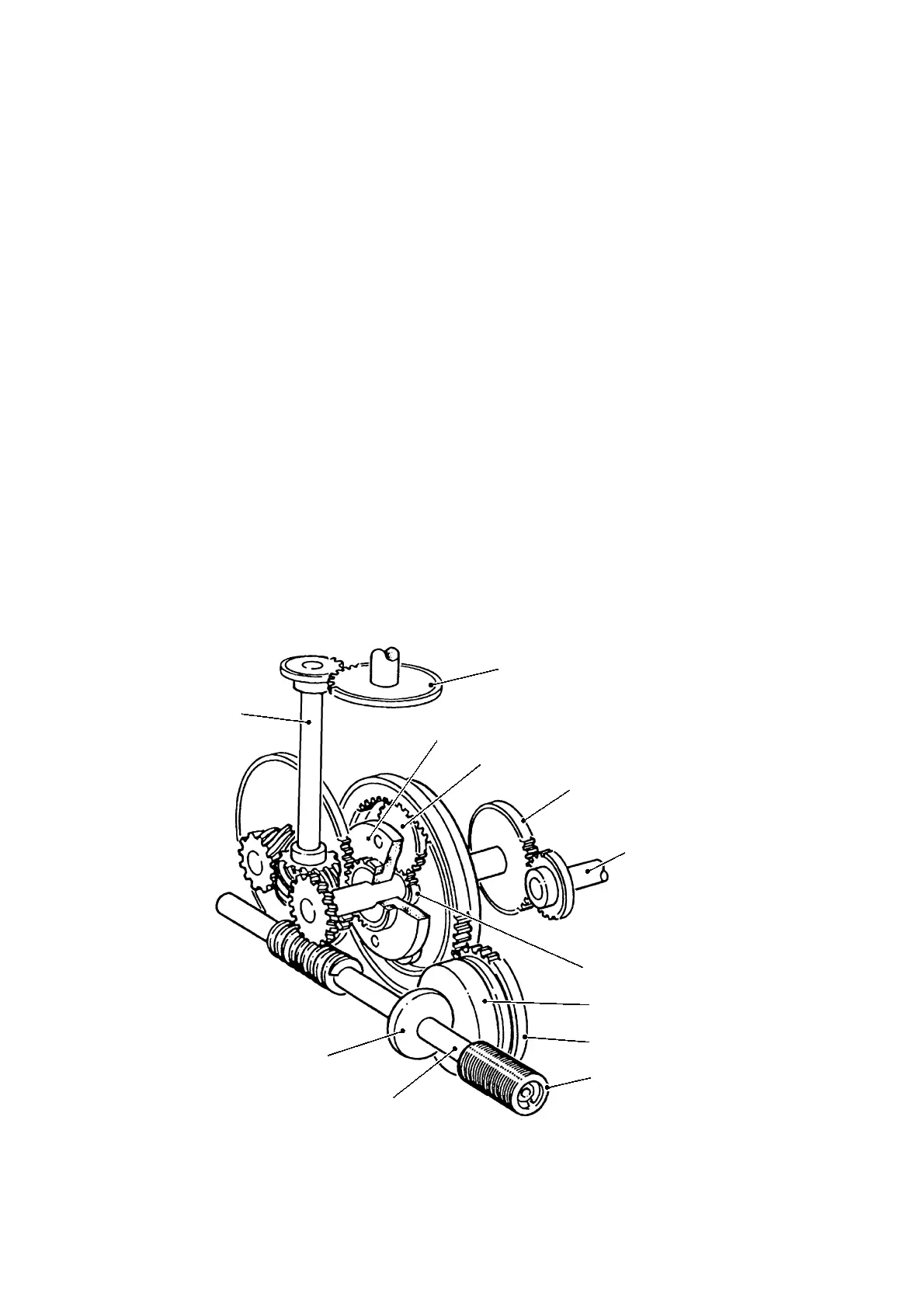

6 CALIBRATING MECHANISM

FIG 2.3 calibrating mechanism GEAR ARRANGEMENT

INTERMEDIATE

SHAFT

REGISTER

DRIVE

PLANET GEAR CARRIER

PLANET GEAR

INPUT GEAR OF CALIBRATING

MECHANISM

OUTPUT SHAFT

OF BULKMETER

SUN GEAR

FRICTION DISC

DISC GEAR

CALIBRATING SCREW

FRICTION ROLLER

WORM SHAFT

S14018

Loading...

Loading...