TP0003B

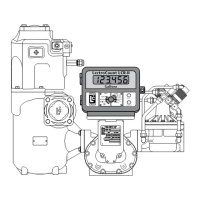

BM METER

Chap 4

Page 1

INSTALLATION, OPERATION & MAINTENANCE

Chapter 4

INSTALLATION, OPERATION AND MAINTENANCE

CONTENTS

Para

Pre-installation 1...................................................................................

Installation 2.......................................................................................

Operation 3.......................................................................................

Maintenance 4.....................................................................................

Storage 5.........................................................................................

Storage Of Water Meters 6..........................................................................

After Storage 7....................................................................................

WARNINGS

WORK MUST BE CARRIED OUT ONLY BY SUITABLY QUALIFIED PERSONNEL.

PRIOR TO COMMENCING WORK, ENSURE THAT ALL AIRPORT/COMPANY SAFETY

PROCEDURES HAVE BEEN COMPLIED WITH.

1 PRE-I NSTALLATION

1.1 Prior to installing a meter carry out the following procedures.

1.2 Flush and drain the body casing.

1.3 Drain the calibrating mechanism by first removing the drain plug and then the cover.

1.4 Thoroughly wash the calibrating mechanism with clean kerosene, refit the cover and drain plug.

1.5 Lubricate the calibrating mechanism with GREASE.

1.6 Refit and wirelock all drain plugs in the body casing.

2 INSTALLATION

2.1 The following notes are for guidance only, installation methods being dependent upon local

regulations and conditions.

Note

Plan space around the installed bulkmeter to allow removal of the rotor assembly for servicing.

2.2 Install the bulkmeter by suspending it in the pipeline by the manifold, this ensures that pipeline

stresses are not transmitted to the meter body. No attempt is to be made to support the meter body

in the installation by any other method.

2.3 When using jointing compound, apply to male threads only to prevent excess compound fouling the

meter mechanism.

2.4 Until all air has been eliminated from the system, the control valve must be opened slowly to prevent

the meter racing and exceeding its maximum rated speed.

Loading...

Loading...