1. Push the O-ring (1) into the groove (2) on the front of the

meter housing.

2. Fasten the front cover (3) to the housing with the cover

screws (4) using the cover socket or open end/box end

wrench.

3. Screw the front drain plug (6) into the front drain plug hole

(7) using the drain plug allen wrench.

4. Push the O-ring (8) into the groove (9) on the rear of the

meter housing.

5. Fasten the rear cover (10) with the cover screws (11)

using the cover socket or open end/box end wrench.

6. Screw the rear drain plug (not shown) into the rear drain

plug hole using the drain plug allen wrench.

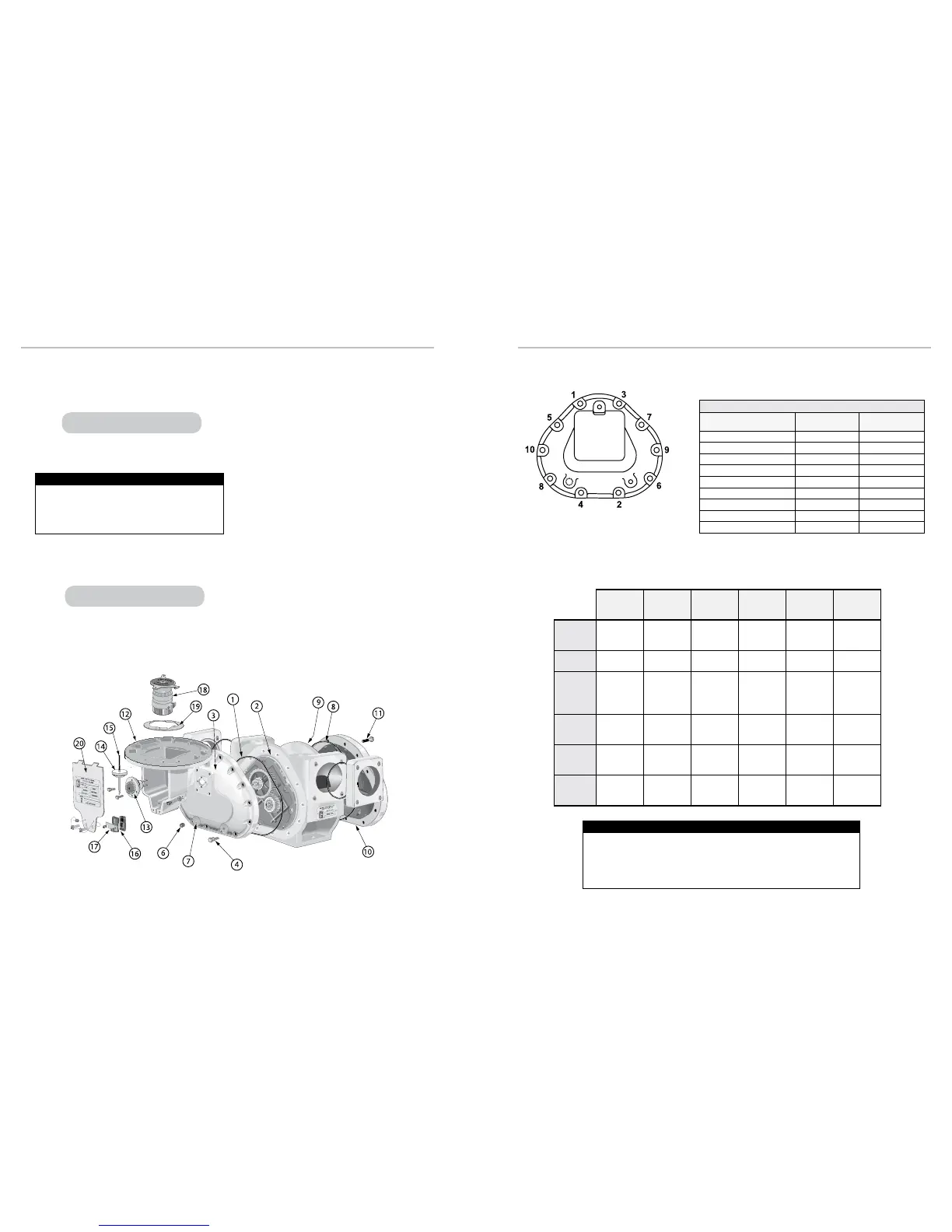

Meter Assembly Exploded View

Grade 5 Fasteners

Bolt Size

Foot-Pounds

NOMINAL*

Newton-Meter

NOMINAL*

#8 (.164) - 32 UNC-2A

2.54 (30.5 in/lb) 3.4

#10 (.190) - 24 UNC-2A

3.75 (45 in/lb) 5.1

1/4” (.250) - 20 UNC-2A

7.3 9.9

5/16” (.3125) - 18 UNC-2A

15.3 20.7

3/8” (.375) - 16 UNC-2A

27 37

7/16” (.4375) - 14 UNC-2A

43 58

1/2” (.500) - 13 UNC-2A

66 90

5/8” (.625) - 11 UNC-2A

132 179

3/4” (.750) - 10 UNC-2A

233 316

*Torque Tolerance is ± 10%

REASSEMBLING THE METER REASSEMBLING THE METER

MA-4

M-5

MA-5

M-7

MA-7

M-10

M-15

M-25

MA-15

M-30

M-40

M-60

M-80

Dust

Cover

Screws

⁵⁄₁₆” hex

wrench

⁵⁄₁₆” hex

wrench

slotted

screwdriver

slotted

screwdriver

slotted

screwdriver

slotted

screwdriver

Drain

Plug

¼” Allen

wrench

¼” Allen

wrench

³⁄₈” Allen

wrench

³⁄₈” Allen

wrench

³⁄₈” Allen

wrench

³⁄₈” Allen

wrench

Meter

Cover

Screws

½” hex

wrench/

socket

½” hex

wrench/

socket

¼” Allen

or

½” hex

wrench/

socket

¼” Allen

or

½” hex

wrench/

socket

⁹⁄₁₆” hex

wrench/

socket

¾” hex

wrench/

socket

Counter

Bracket

Screws

³⁄₈” hex

wrench/

socket

³⁄₈” hex

wrench/

socket

N/A

³⁄₈” hex

wrench/

socket

N/A

³⁄₈” hex

wrench/

socket

Bearing

Plate

Screws

⁵⁄₁₆” hex

wrench/

socket

⁵⁄₁₆” hex

wrench/

socket

⁵⁄₁₆” hex

wrench/

socket

⁵⁄₁₆” hex

wrench/

socket

⁷⁄₁₆” hex

wrench/

socket

½” hex

wrench/

socket

Rotor

Gear

Screws

⁵⁄₁₆” hex

wrench/

socket

³⁄₈” hex

wrench/

socket

³⁄₁₆” Allen

wrench

³⁄₁₆” Allen

wrench

³⁄₁₆” Allen

wrench

³⁄₁₆" Allen

wrench

Please apply these techniques when repairing meters in the eld.

1. Prior to installation, apply a small amount of Locquic Primer N764 to each screw.

2. Apply a light coat of Loctite 242 in three even strokes to each screw. The Loctite

and Locquic primer are not to be applied to the female connection in the rotor.

ROTOR GEAR SCREWS

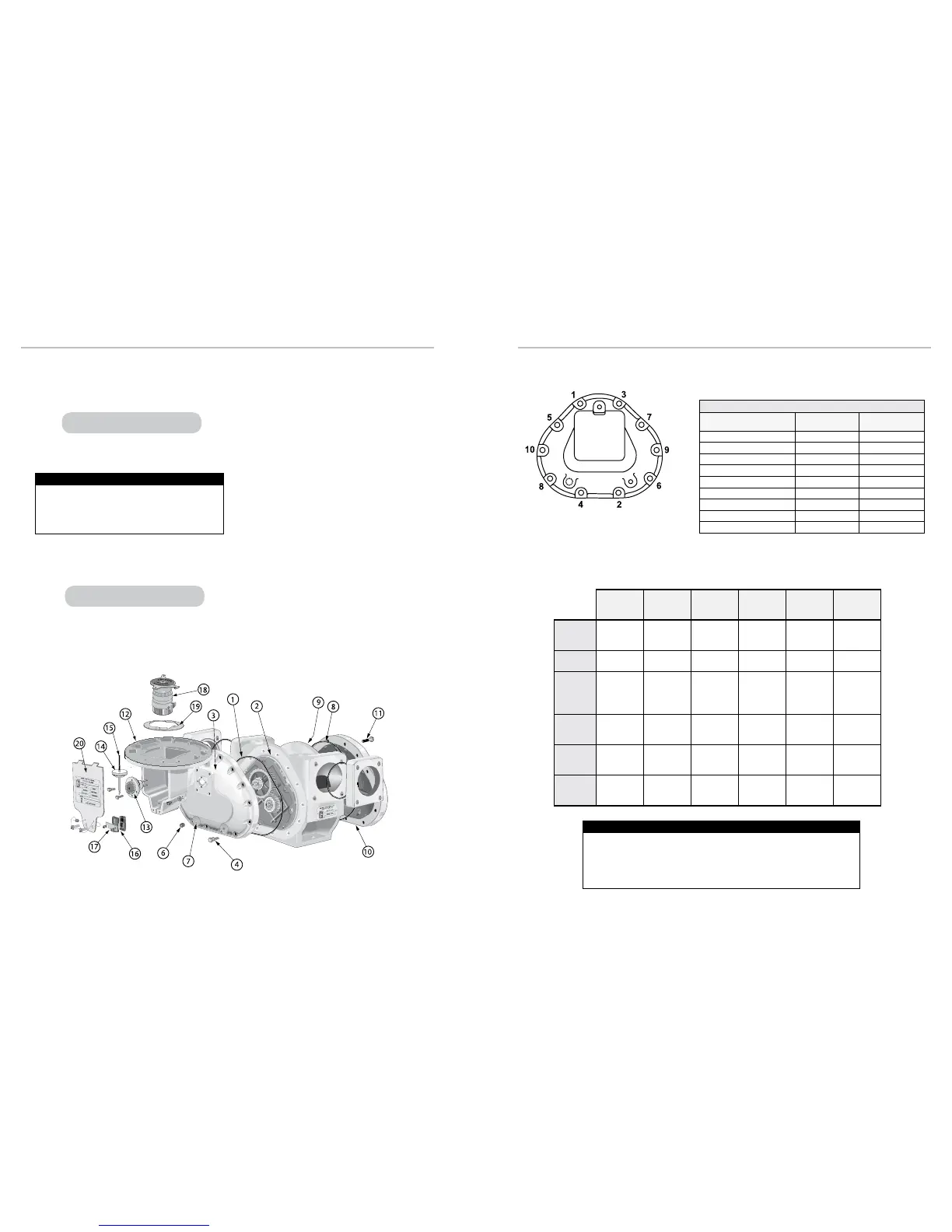

LC recommends tightening the front and rear cover screws

in a criss-cross or “star” pattern with a minimum of two

passes. First pass should be at half-torque. Final pass(es)

should be at full torque. This method will ensure uniform seal

compression on cover O-ring or gasket. See page 21.

Tightening Front and Rear Covers

M-60 and M-80 models use a at gasket.

M-60 and M-80 models use a at gasket.

7. Screw the counter bracket (12) onto the front cover using

the counter bracket screws.

8. Insert the packing gland assembly (13) through the

counter bracket and into the cover plate. Make sure the

forks of the packing gland drive are in the slots of the

packing gland driver attached to the blocking rotor gear.

9. Screw the packing gland retaining plate onto the

counter bracket using the two retaining plate screws.

See Servicing the Packing Gland on page 15 for more

information.

10. Return the adjuster drive gear (14), the adjuster drive

shaft (15), and the drive shaft bushing (16) to the inside

of the counter bracket. Make sure the drive gear is in its

original position. See Reversing the Meter Registration on

page 10 for more information.

11. Screw the retaining spring (17) over the drive shaft

bushing and slide the retaining ring back into the slot on

the drive shaft.

12. Screw the standard adjuster (18) onto the adjuster

mounting plate (19).

13. Insert the standard adjuster and adjuster mounting plate

through the top of the counter bracket and onto the

adjuster drive shaft. Screw the mounting plate onto the

counter bracket.

14. Screw the dust cover onto the counter bracket using the

dust cover screws.

21

20

Loading...

Loading...