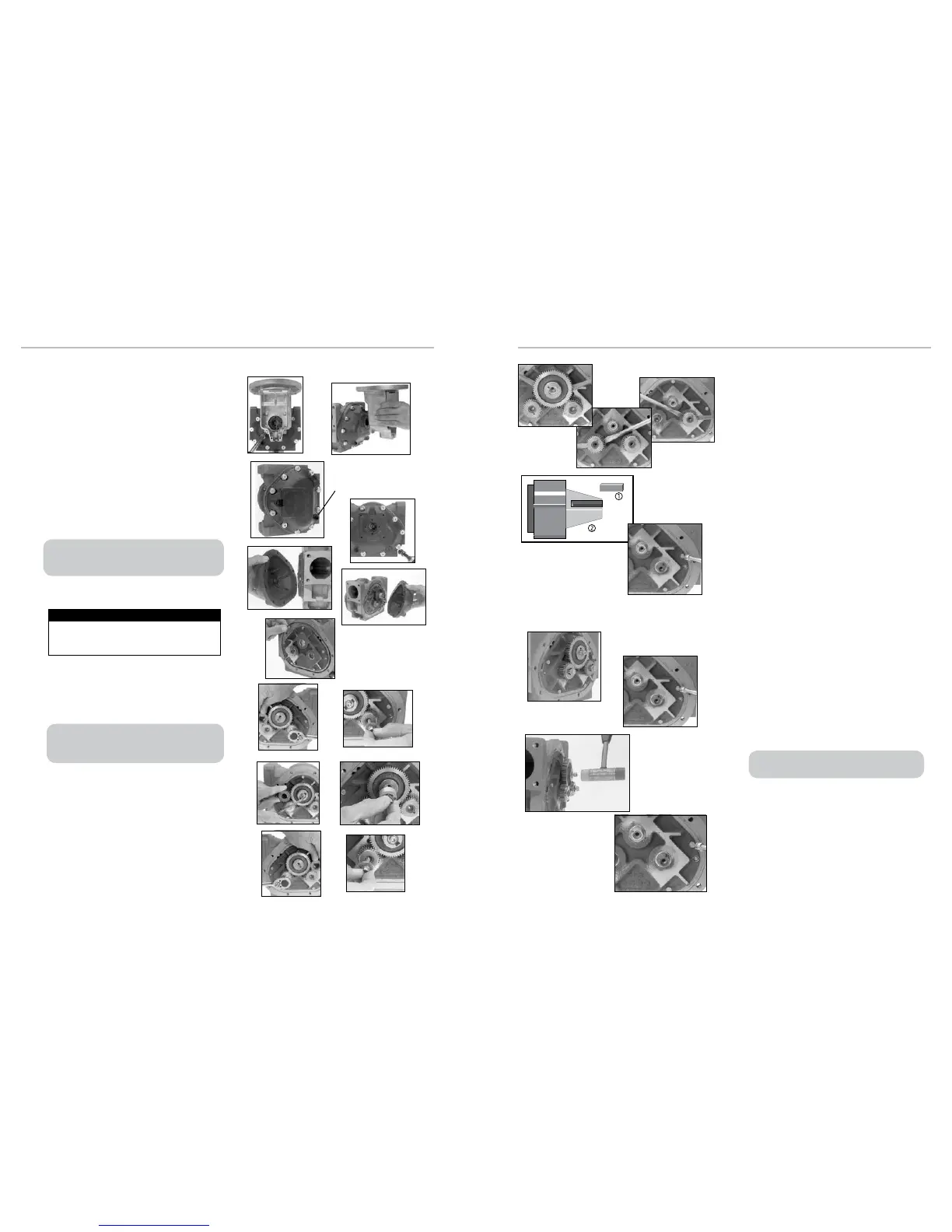

1. Remove the counter bracket screws with a box wrench or

socket driver. The counter bracket can be removed with

or without removing the adjuster assembly.

2. Turn the meter on either the inlet or outlet side. Let

it stand to allow the product to drain from the meter

chamber.

3. Locate the drain plugs on the front and rear covers.

Remove the drain plugs using an allen wrench. Let the

meter stand to allow product to drain from the front and

rear covers.

4. Use a socket wrench or box end wrench to remove the

screws securing the front cover. Remove the screws

that hold the rear cover. The number of screws will vary

depending on meter size.

5. Remove the front and rear covers.

6. Carefully remove the O-rings / at gaskets from front and

rear of the housing.

7. Use the rotor gear wrench (or a socket driver) to remove

the right displacement rotor gear screw and washer.

Hold a spare displacement rotor gear between the right

displacement rotor gear and the blocking rotor gear to

keep them from turning (if unavailable, use a shop rag

between gear teeth).

8. Use the rotor gear wrench (or a socket driver) to remove

the blocking rotor screw and the packing gland driver

held by the screw. Hold the spare gear between the left

displacement rotor gear and blocking rotor gear.

9. Use the rotor gear wrench (or a socket driver) to remove

the left displacement rotor gear screw and washer. Hold

the spare gear between the right displacement rotor gear

and the blocking rotor gear.

Undamaged Buna or Viton O-rings may be reused. Flat

gaskets and PTFE O-rings should always be replaced

and never reused.

O-rings & Flat Gasket Replacement

DISASSEMBLING THE METER DISASSEMBLING THE METER

Meters

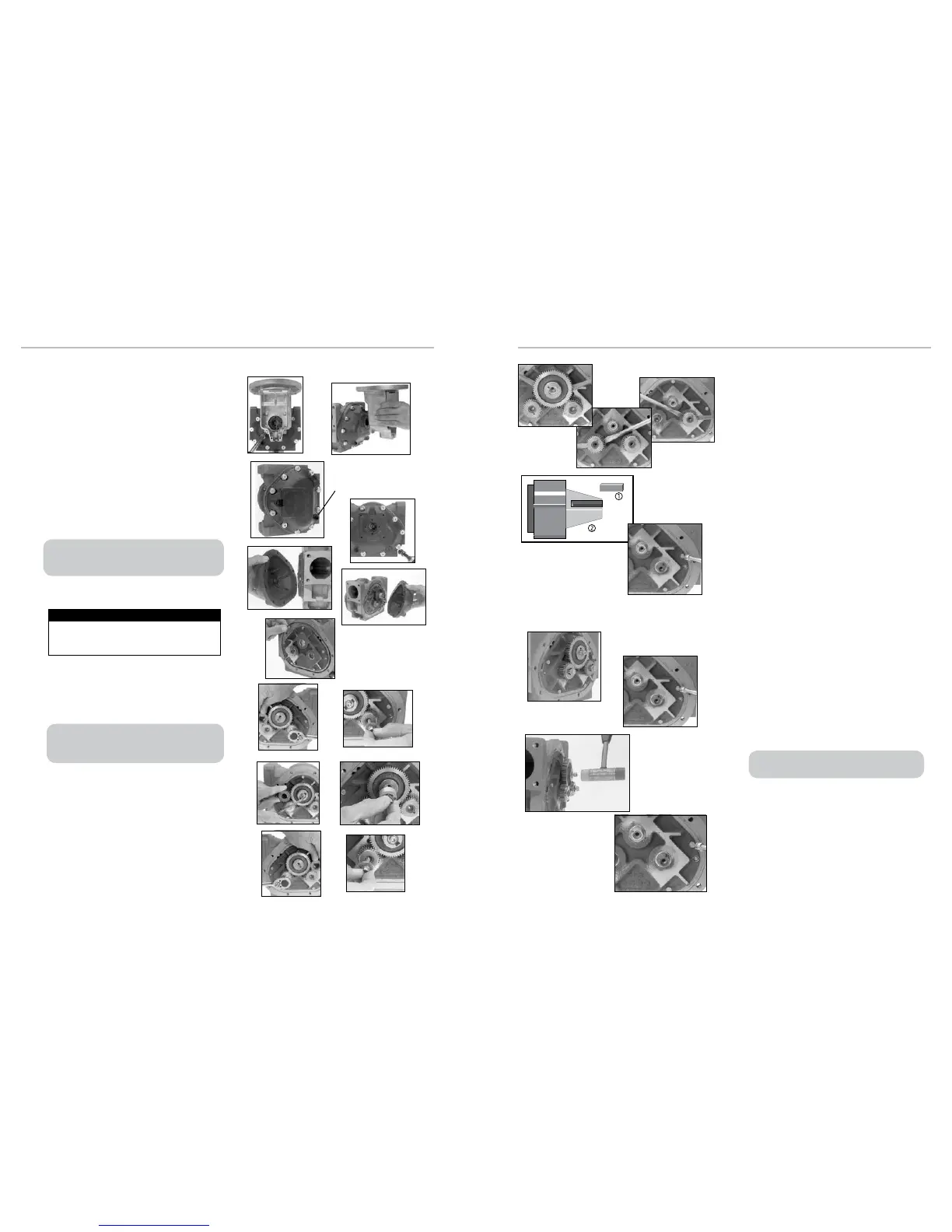

1. Insert two standard screwdrivers behind the blocking

rotor gear: Gently pry the gear off its rotor tapered end. If

the gears show signs of corrosion, or do not pry off easily,

see To remove corroded rotor gears: below.

2. Use the same method to remove the left rotor gear and

the right rotor gear. If the gears show signs of corrosion,

or do not pry off easily, see To remove corroded rotor

gears: below.

3. As each gear comes off the rotor remove the key (1)

from the rotor keyway (2). Save the key to use when

reassembling the meter.

4. Use the bearing plate wrench (or a socket driver) to

remove the screws that hold the front bearing plate to the

meter housing.

5. Remove the screws that hold the rear bearing plate to the

housing.

1. On the back of the meter housing, remove the screws

that hold the rear bearing plate to the housing using the

bearing plate wrench (or a socket driver). The number of

screws will vary depending on meter size.

2. Replace all three rotor gear screws, without washers.

Screw them halfway onto each of the rotor ends.

3. With a plastic or non-metallic mallet, tap on the heads of

the screws on the rotor ends lightly and equally, slowly

driving the rotors off of the rotor gears. As you tap on the

screws, the rear bearing plate and the rotor assembly will

separate from the housing.

4. Use the bearing plate wrench (or a socket driver) to

remove the screws that hold the front bearing plate to the

meter housing. The number of screws will vary depending

on meter size.

MA-4, M-5, and MA-5 old style models, M-60 and M-80

current models have a driven reduction gear attached with

a shoulder bolt to the center of the front bearing plate.

MA-4, M-5, and MA-5 old style models, M-60 and M-80

current models have rotor gears on the meter back.

All other models have rotor gears are on the front.

Drain Plug

For carbon insert bearing plates, remove the rear plate

rst and then each rotor as it is hand supported.

17

16

Loading...

Loading...