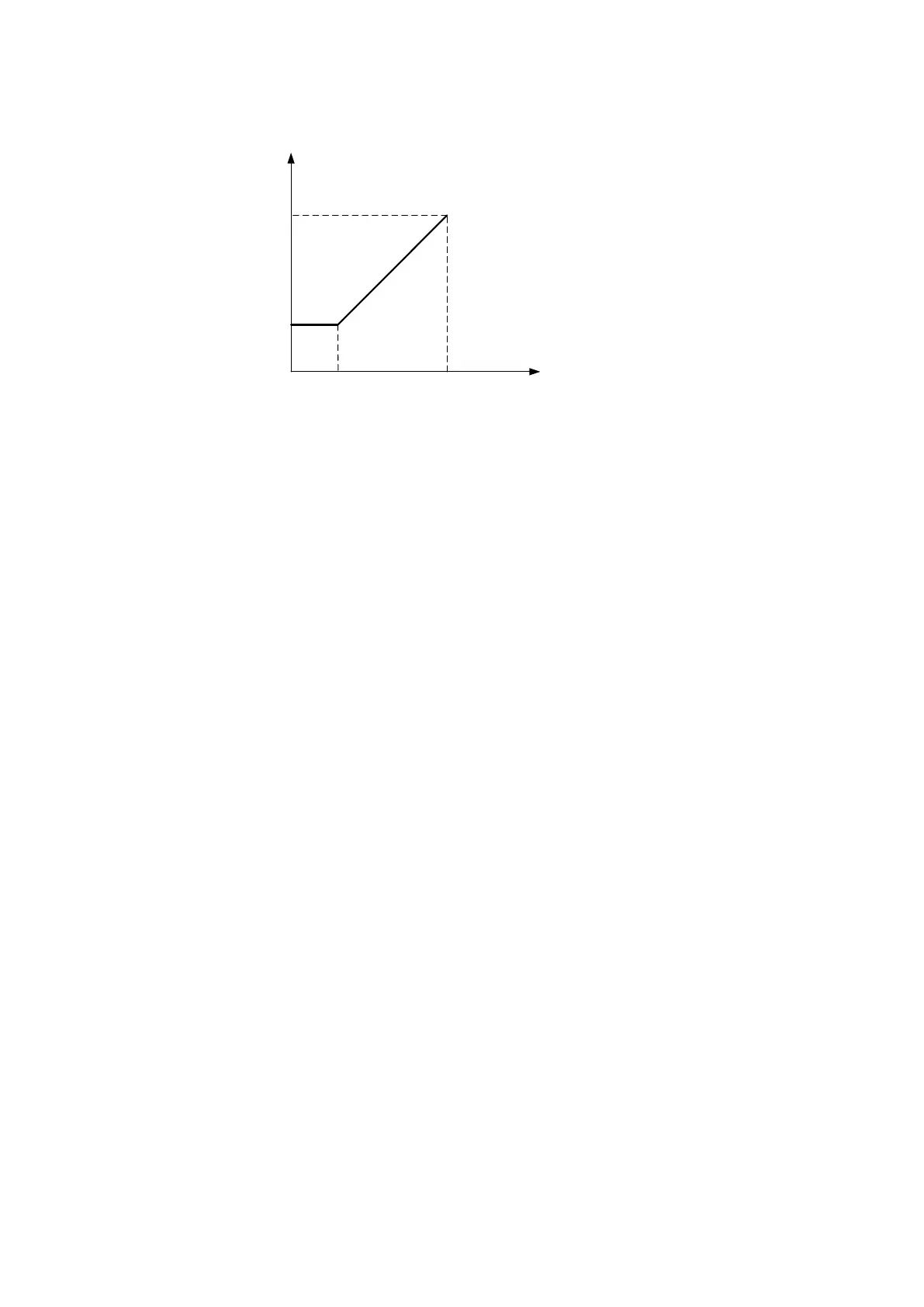

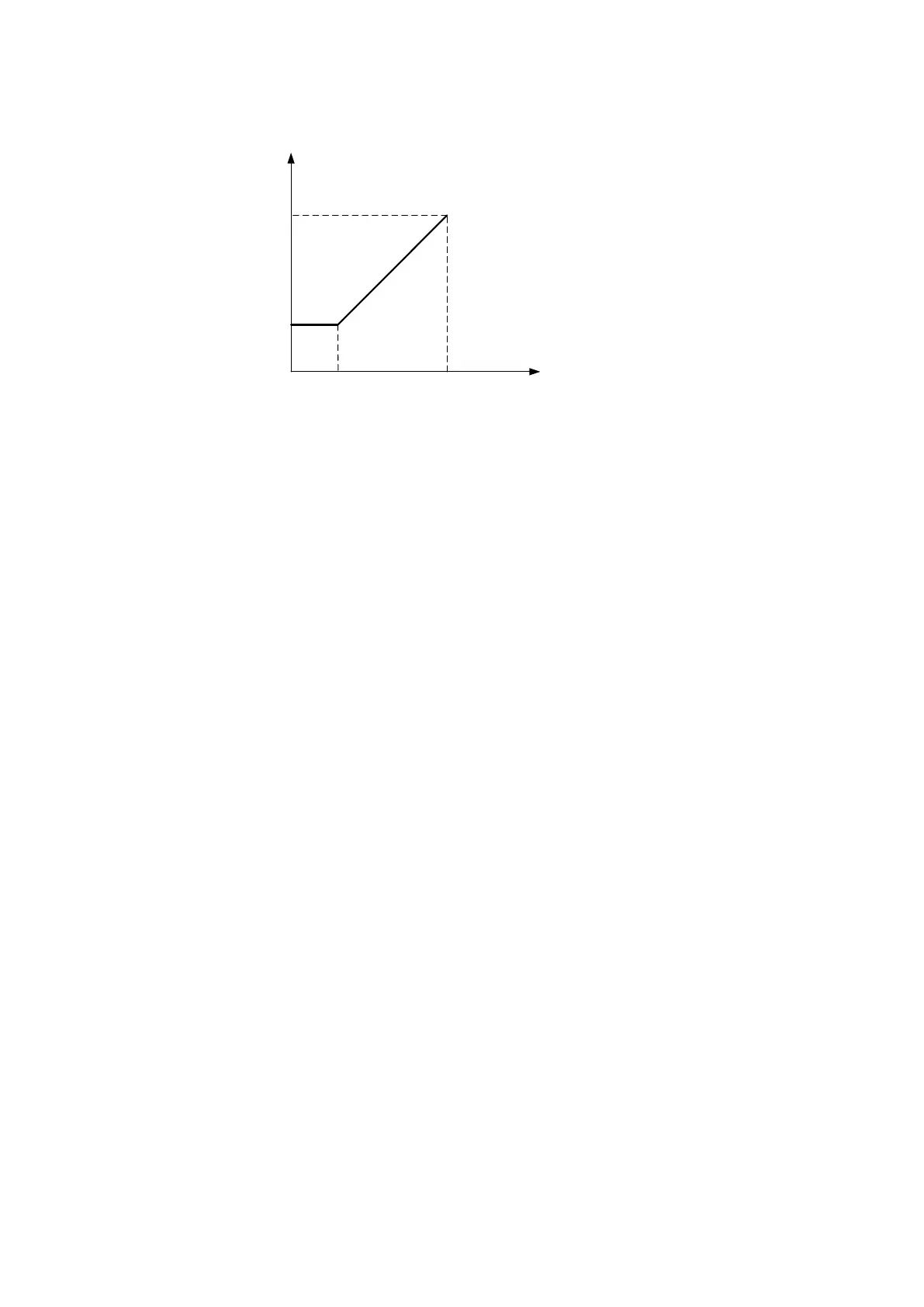

120

100%

Analog input level

0

( 4mA )

10 V

( 20mA )

Stall prevention level during Run

30%

3 V

( 8.8mA )

Figure 6.66 Stall Prevention Level Using Analog Input

8 : PID Feedback

Sets the PID feedback by the analog input value. To use this function, enable the PID control in

b5-00.

9 : PID Target

Sets the PID target value by the analog input value. The frequency command entered by the

command source selected in b1-00 (Frequency Command Selection 1) is disabled. To use this

function, enable the PID control in b5-00.

10: Differential PID Feedback

Sets the differential PID feedback by the analog input value. The difference of the PID feedback

input value and the differential feedback input value is used to calculate the PID input.

11 : Overtorque/ Undertorque Detection

Sets the detection level for overtorque and undertorque by the analog input value. Use the

combination of this function and P6-00 (Overtorque/ Undertorque Detection Selection 1). This

is the secondary source for P6-01 (Overtorque/ Undertorque Detection Level 1). When the

input is 100% (10 V, 20 mA), the motor rated torque will be 100%. Refer to P6 (Overtorque/

Undertorque Detection) for details.

12 to 17 : Retain

18/19 : Communication Mode

If the terminal is assigned to 18 or 19, ther input signal can be used as an analog input from

the upper controller via Modbus.

Loading...

Loading...