Operating Manual

Tangential Rolling System T18F - T27F

36

ET-183839

ET-3

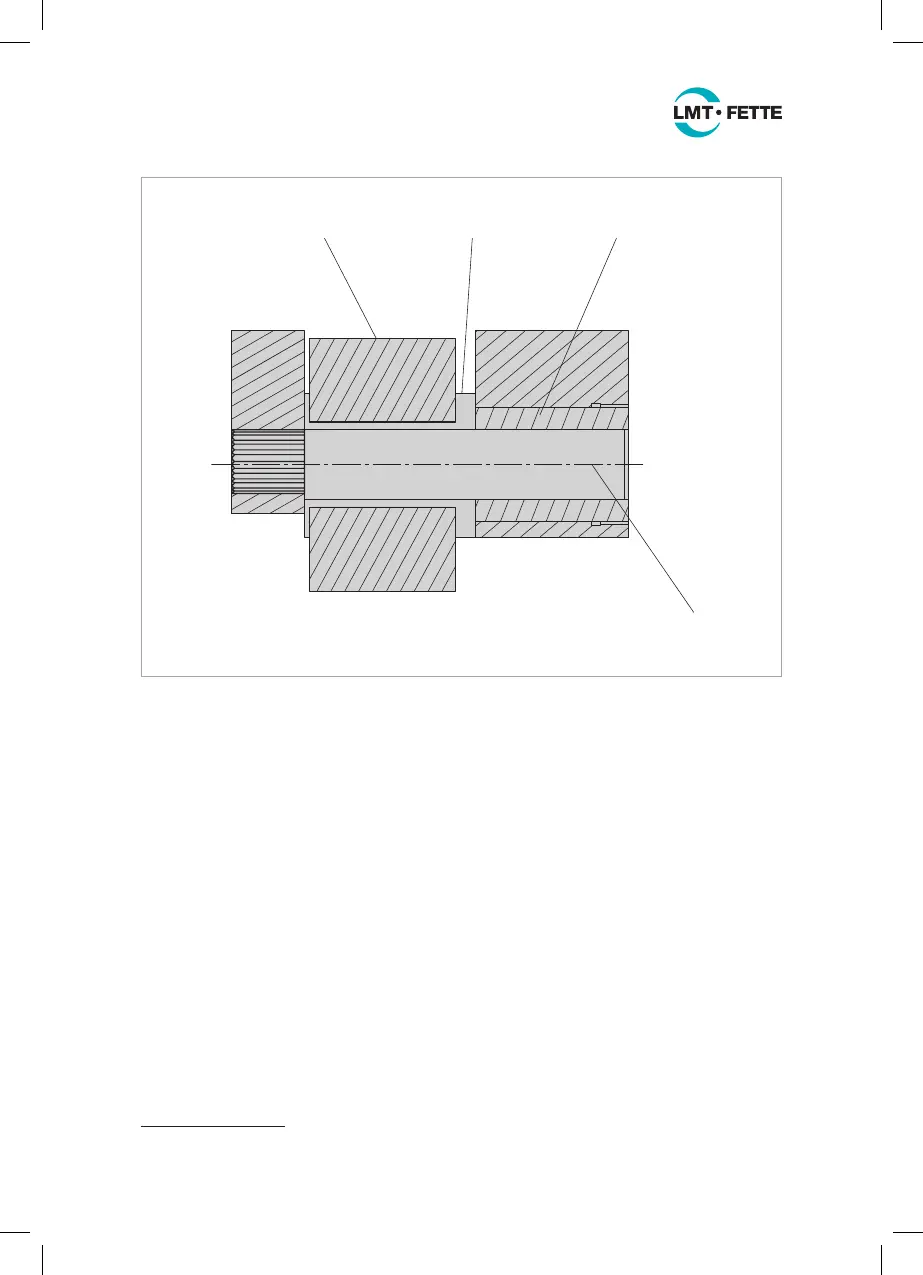

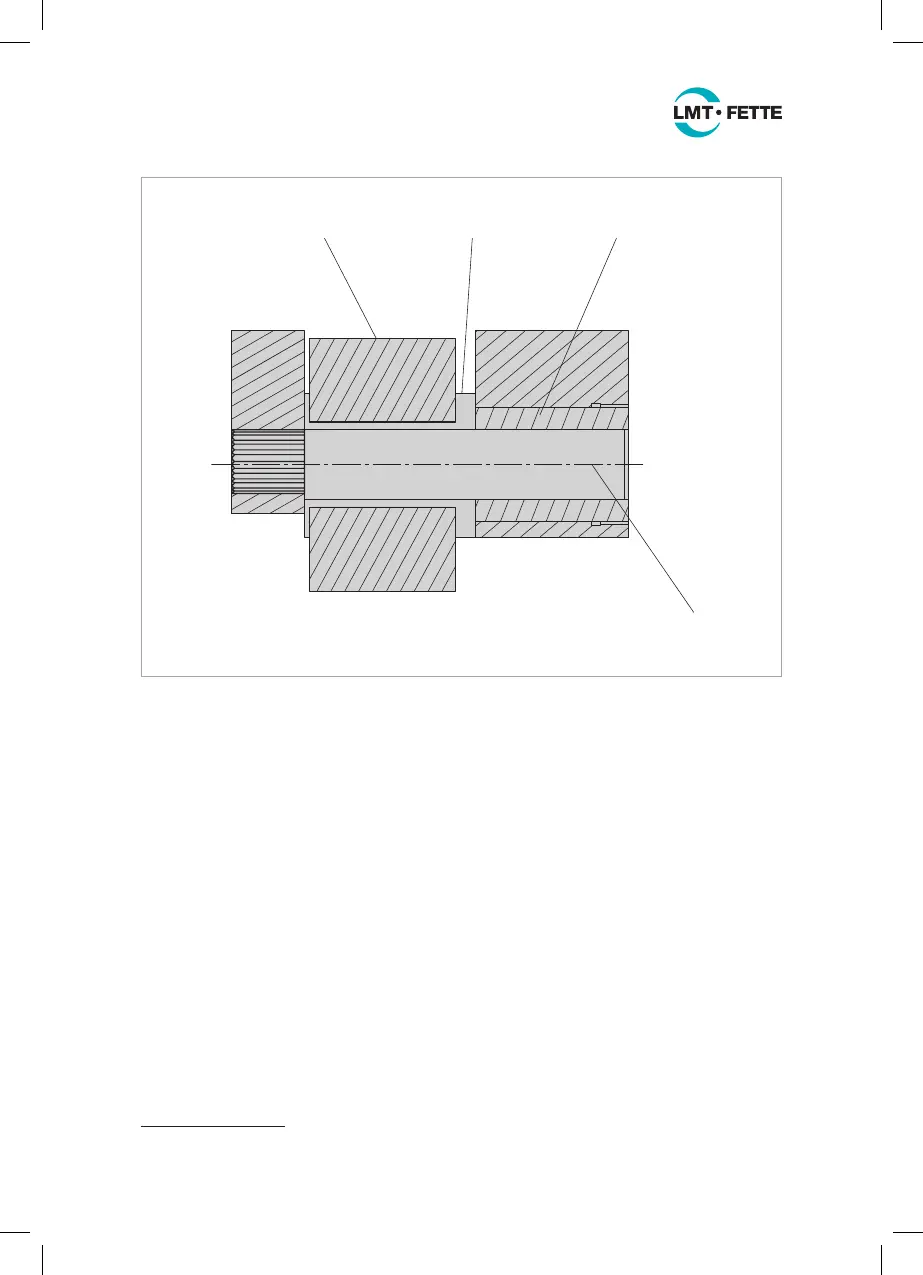

Figure 21: Kit for knurling and burnishing

2. The maximum roll width corresponds to the width of a normal thread roll.

3. Preparing the workpiece

For burnishing and knurling the blank diameter d

A

should be within a tolerance of

±0.015 mm l 0.0006 inch.

For burnishing the blank diameter d

A

must be selected approx. 0.04 mm l 0.0016

inch larger than the desired finished size. Here the achievable surface quality and

diameter tolerance is always dependent on the surface quality and diameter toler-

ance of pre-machining.

For knurlings the nominal diameter d is specified. This corresponds to the major

diameter of the workpiece

5

. The blank diameter d

A

of the workpiece for the forms

RAA (knurling with axially parallel grooves), RBL (left-handed knurling), RBR (right-

handed knurling), RGE (left-right-handed knurling) und RKE (cross knurling) is ap-

proximately calculated from:

d

A

= d – h [mm]

5

As per DIN 82, Edition 1973

LMT_Bedienungsanleitung_T18F_T27F_e.indd 36 02.08.11 17:40

Loading...

Loading...