SECTION 3 MAINTENANCE

3-1 Maintenance Schedule

Good maintenance is essential to safe,

economical and zero-failure operation, and is also

good for environment protection. Under hot or dusty

operating conditions some maintenance operations

should be performed more frequently, as indicated

by the footnotes to the table.

Keep a log of maintenance performed and the

hours run. Recording maintenance will help you

keep it regular and provide a basis for supporting

warranty claims.

Accidental starting of the generator

set during maintenance can cause severe

personal injury or death. Before performing

maintenance, disconnect the spark plug wire

from the spark plug.

A hot generator set can cause

severe burns. Always allow the generator set

to cool adequately before performing any

maintenance or service.

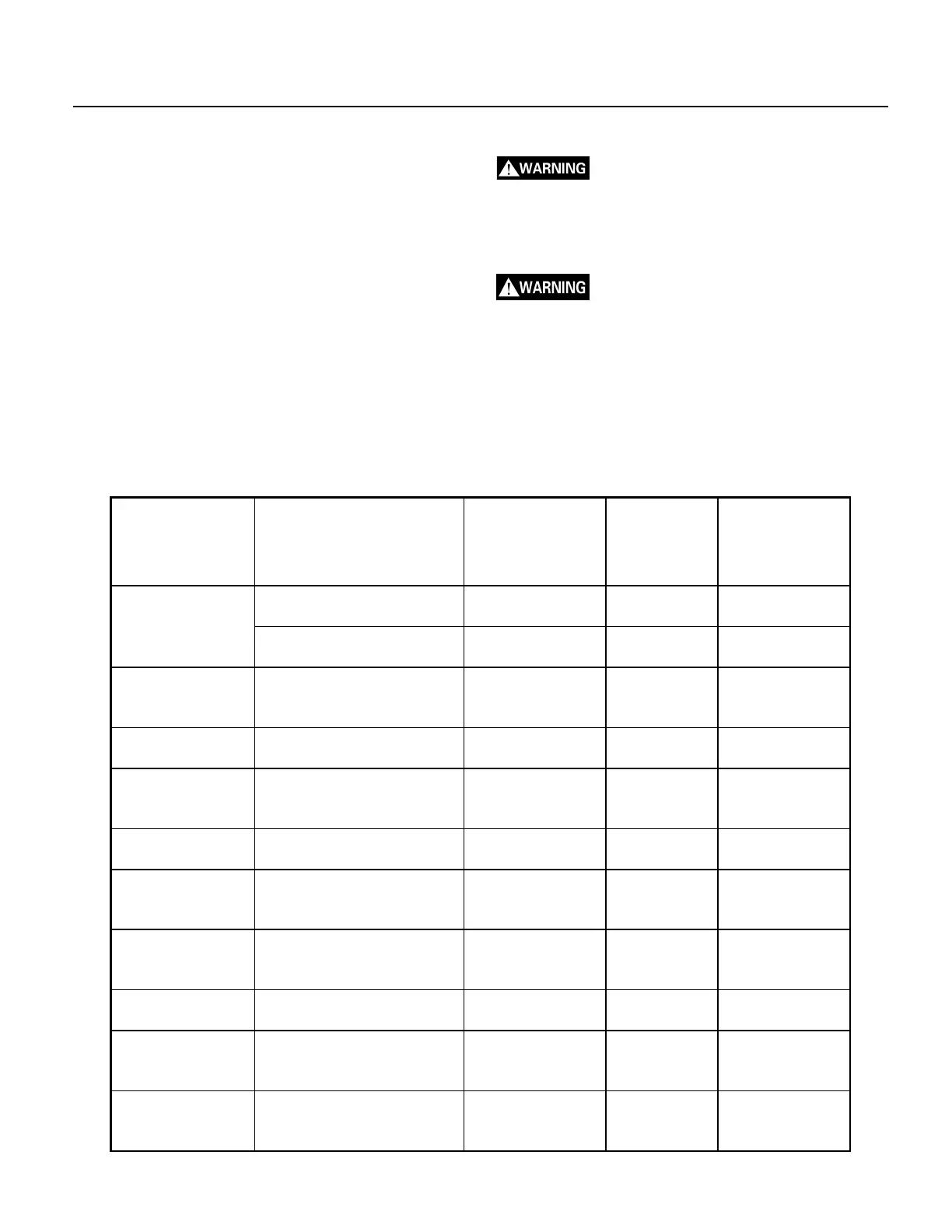

PERIODIC MAINTENANCE SCHEDULE

Item Routine

Pre-operation

check(daily)

6 months

or 100 Hr

12 months

or 300 Hr

Engine oil

Check oil level

in engine.

○

Replace ○ (1)

Spark plug

Clean and replace

○

Fuel

Check fuel level

and leakage.

○

Fuel hose

cracks or damage,

○

Air filter

○ (2)

Muffler screen

Clean and replace

○

Spark arrester

Clean and replace

○

Fuel filter

Clean and replace

if necessary.

○

Crankcase

breather hose

for cracks or damage.

○

Cylinder head

cylinder head

★

- 6 -

Loading...

Loading...