Messages

- 28 - 02.16909.2759.9-00

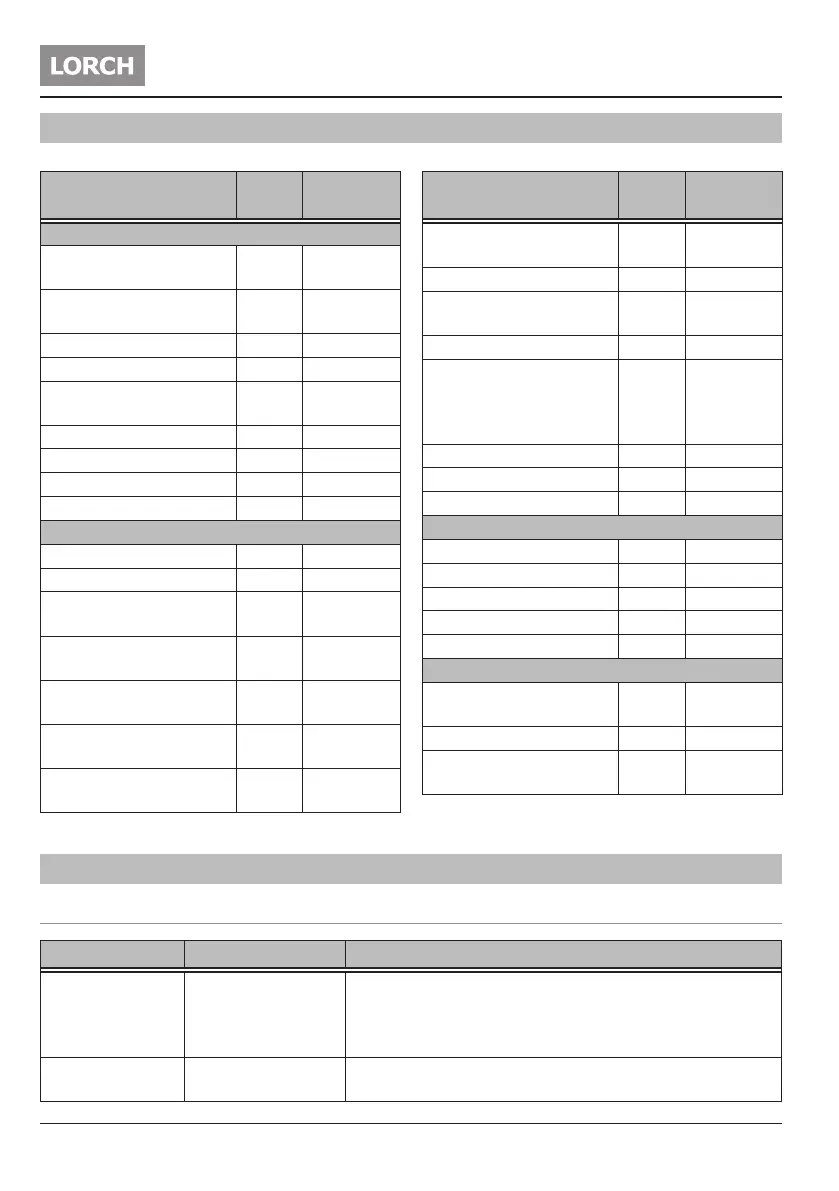

15 Technical data

Technical data Units

MicorStick

160

Welding

TIG welding area (I

2min

-

I

2max

/U

2min

-U

2max

)

A/V

15...160/

10,6...16,4

Electrode welding area

(I

2min

-I

2max

/U

2min

-U

2max

)

A/V

10...150/

20,4...26,0

Idle voltage U

0

=

U

S

V/DC 70...98

Idle voltage U

r

(VRD) V/DC 13 - 15

Power setting

innitely

variable

Slope characteristic falling

Welding current at ED 100%

A 110

Welding current at ED 60%

A 120

ED at max. current % 30

Mains

Mains voltage (50/60 Hz)

V 230/1~

Positive mains tolerance % 15

Negative mains toler-

ance

% 40

Input power S

1

(100%/40°C)

kVA 3,3

Input power S

1

(60%/40°C)

kVA 3,6

Input power S

1

(max.

current)

kVA 5,2

Current input I

1

(100%/40°C)

A 14,2

Technical data Units

MicorStick

160

Current input I

1

(60%/40°C)

A 15,6

Current input I

1

(max.Strom)

A 22,5

Power factor cos φ (for

I

2 max.

)

0,99

Power factor λ for I

2

max 0,97

Max. permissible sys-

tem impedance Zmax

in acc. with IEC 61000-

3-11/12

mΩ 321

Mains fuse A/tr 16

Mains connection mm² 3x 2,5

Mains plug Schuko

Machine

Protection class (EN 60529)

IP 23S

Insulation class F

Cooling method F

Noise emission dB(A) < 70

Designation CE, S

Dimensions and weights

Dimensions (LxWxH) mm

360 x 130

x 215

Weight MicorStick 160 kg 4,9

Weight MicorStick 160

Accu-ready

kg 4,2

*) measured at 40° C environmental temperature

ED = Switch-on duration

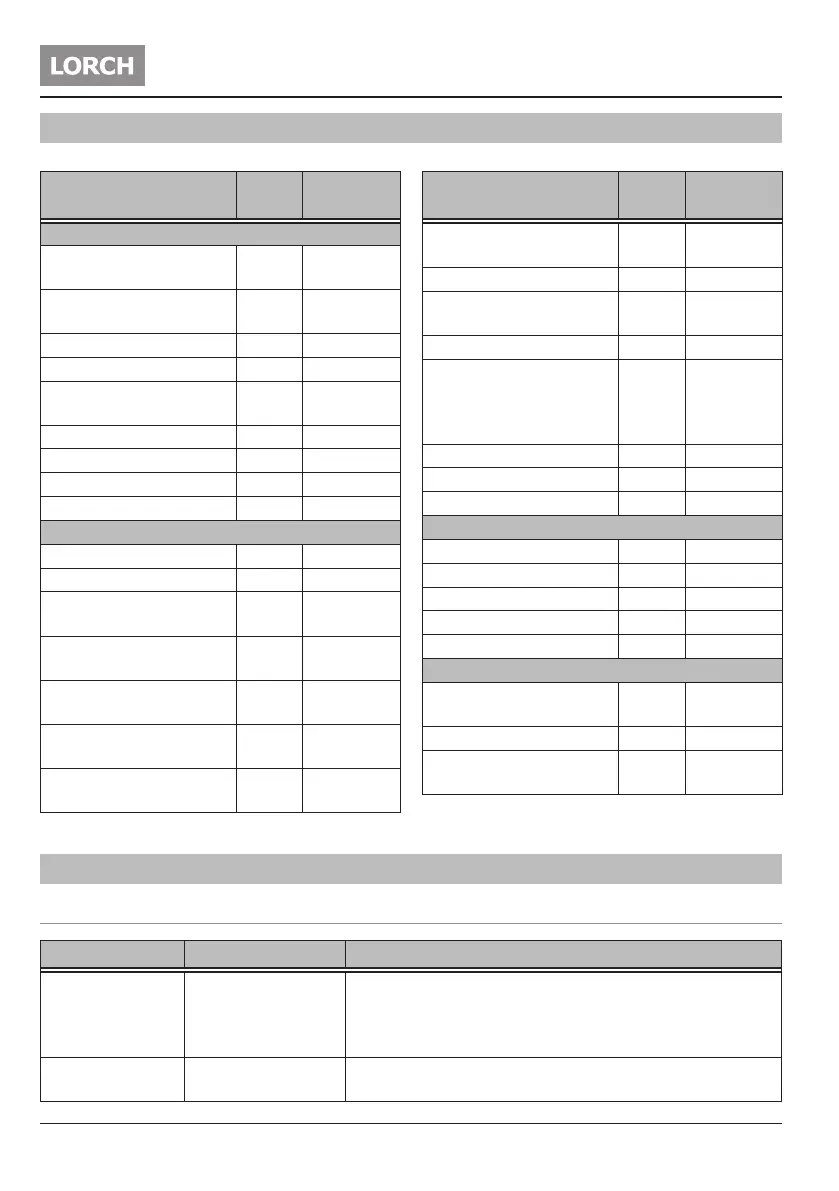

16 Messages

16.1 Error messages (BasicPlus)

Fault Possible cause Rectication

Fault LED 10

ashes

Machine error Switch the machine off. When all the displays have gone

out, leave the system switched off for at least 1 minute.

Switch the system on again. If the fault persists, contact

the Service department.

Fault LED 10 lit

continuously

ED exceeded, ma-

chine has overheated

Let the machine cool down whilst switched on

Loading...

Loading...