2. Troubleshooting

25

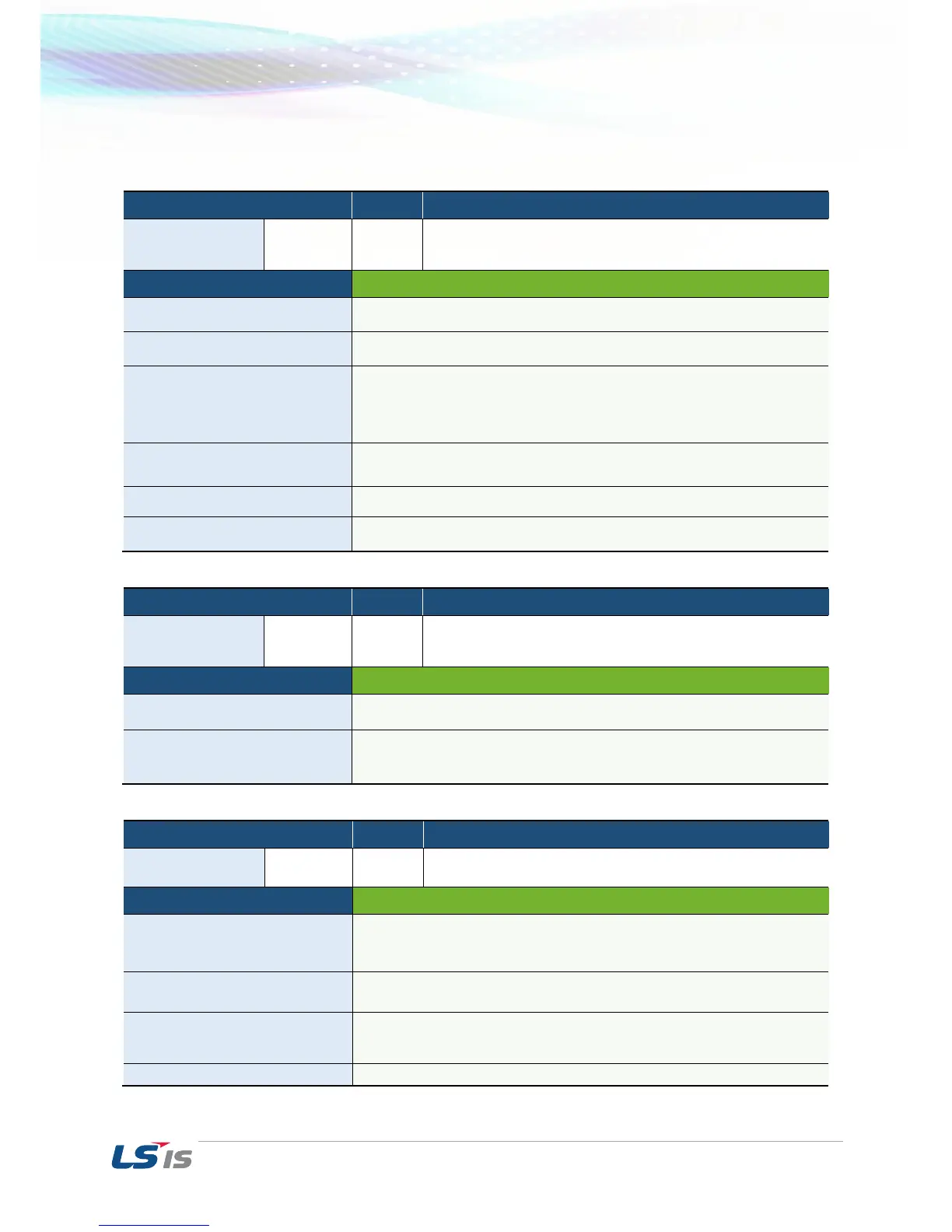

Troubleshooting Fault Trips 2.1.2

Refer to the following tables for solutions to fault trips or warnings.

Occurs when the motor load exceeds the value that was set

for the motor overload trip. Operation will resume after setting

PRT-20 at a value other than 0

The load is greater than the

motor’s rated capacity.

Make sure the motor and inverter has the appropriate capacity ratings.

Replace the motor and inverter that has a bigger capacity.

The value set for overload trip

level (PRT-21) is too small.

Increase the setting value.

There is a fault with the output

module (IGBT).

Refer to 3.1.4 Check Input/Output Module to identify the fault cause of

the output module (IGBT).

DO NOT operate the inverter. Contact the retailer or the LSIS Customer

Service Center.

The mechanical brake of the

motor is operating too fast.

Check the mechanical brake.

The torque boost level is too high

Reduce the torque boost level.

Acc/Dec time is too short compared

to the load inertia (GD2).

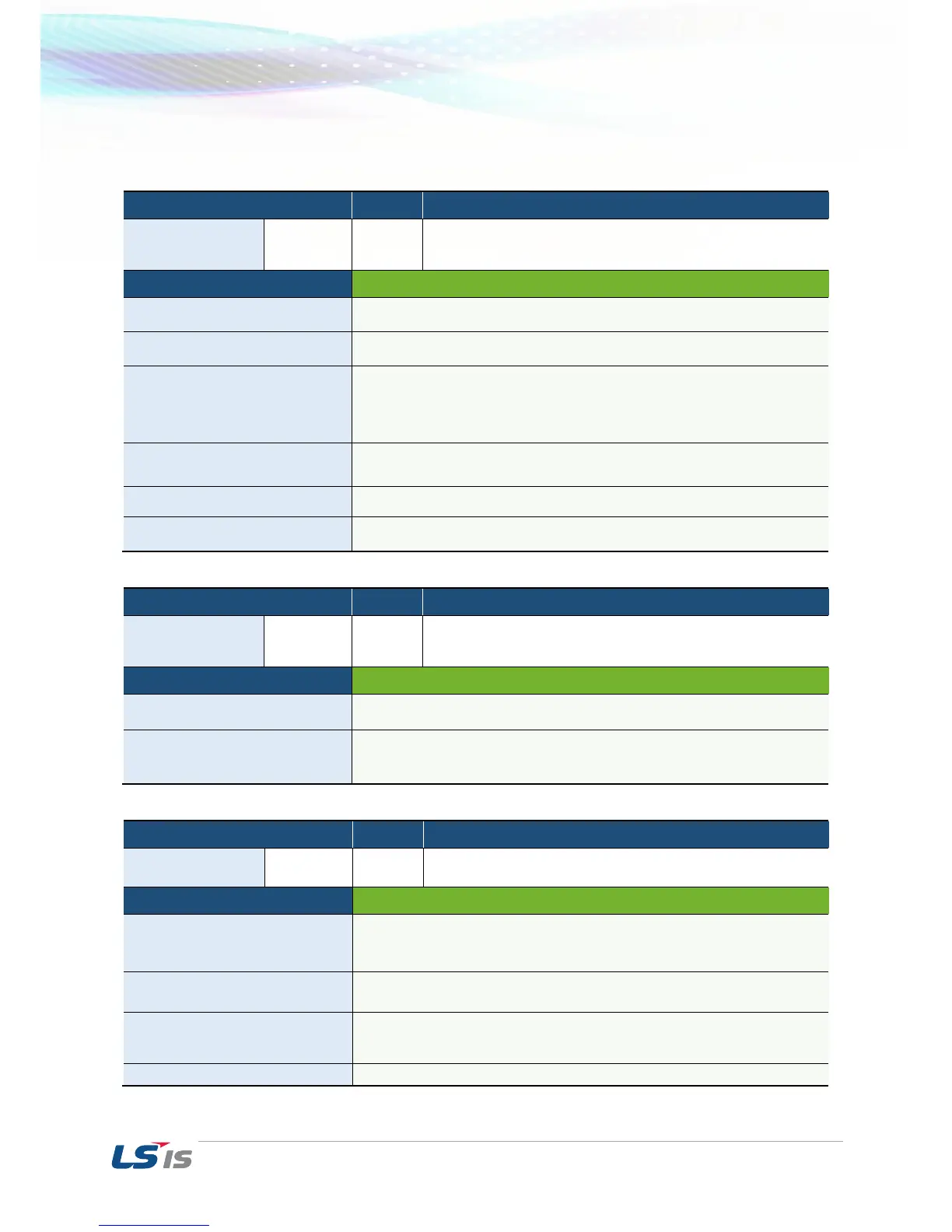

Occurs when the motor load is less than the value that was

set for the motor underload level. Operation will resume after

setting PRT-27 at a value other than 0

There is a motor-load connection

problem.

Replace the motor and inverter with models with lower capacity.

The set value for underload level

(PRT-24) is less than the system’s

minimum load.

Reduce the set value for the underload level.

Occurs when the Inverter output current exceeds 180% of

the rated current.

Acc/Dec time is too short

compared to the load inertia

(GD2).

Inverter load is greater than the

rated capacity.

Replace the inverter that has a bigger capacity.

The inverter produced an output

while the motor was not

operating.

Operate the inverter after the motor stopped or use the speed search

function (CON-70).

The mechanical brake of the

Check the mechanical brake.

Loading...

Loading...