12

damage caused by dirt, road salt, and other debris that may enter the pump. Please refer to the

Pump Operation section for more information.

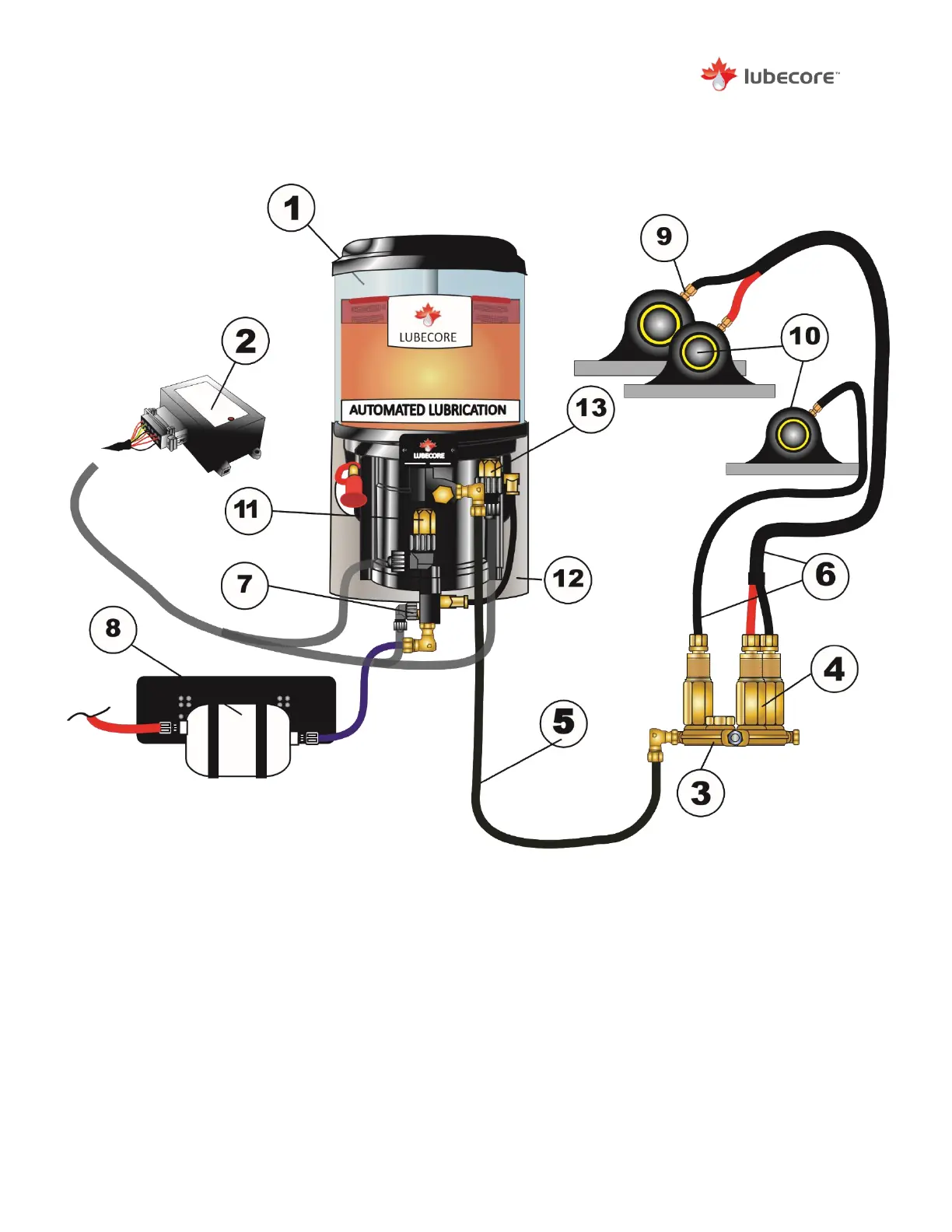

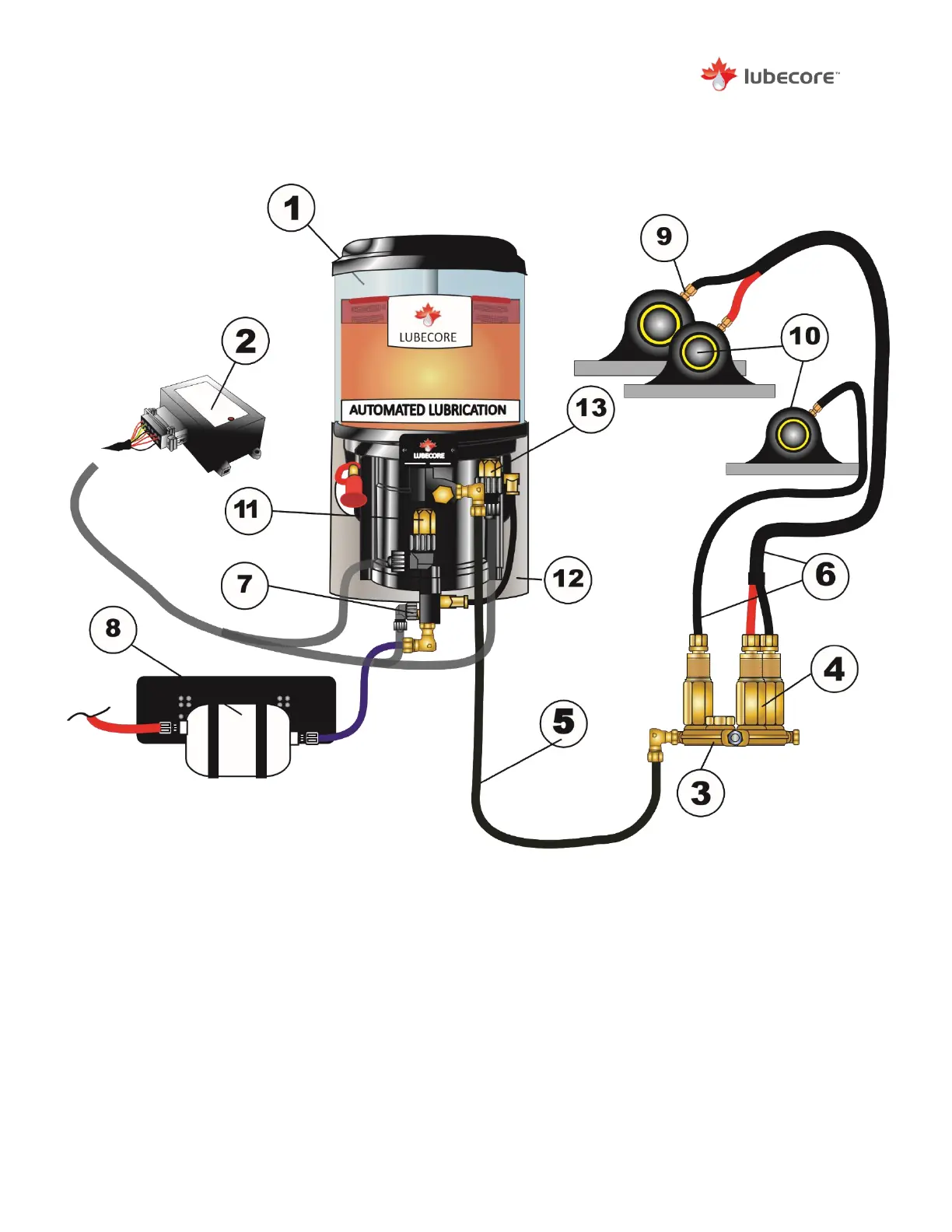

Figure 2 – Standard Lubecore Automated Lubrication System Layout on a Truck

With the air pressure removed, lubricant pressure in the primary tubing returns to zero and

excess lubricant is recycled back into the pump. Once all the grease pressure has been

removed, the reloading process within the injectors begins. Please refer to the injector

operation section for more information.

After the timer deactivates the solenoid, the system program sets the pause time interval back

to the start of the pre-set value and initiates another countdown (as long as the timer is supplied

with power).

Loading...

Loading...