14

Pump Operation

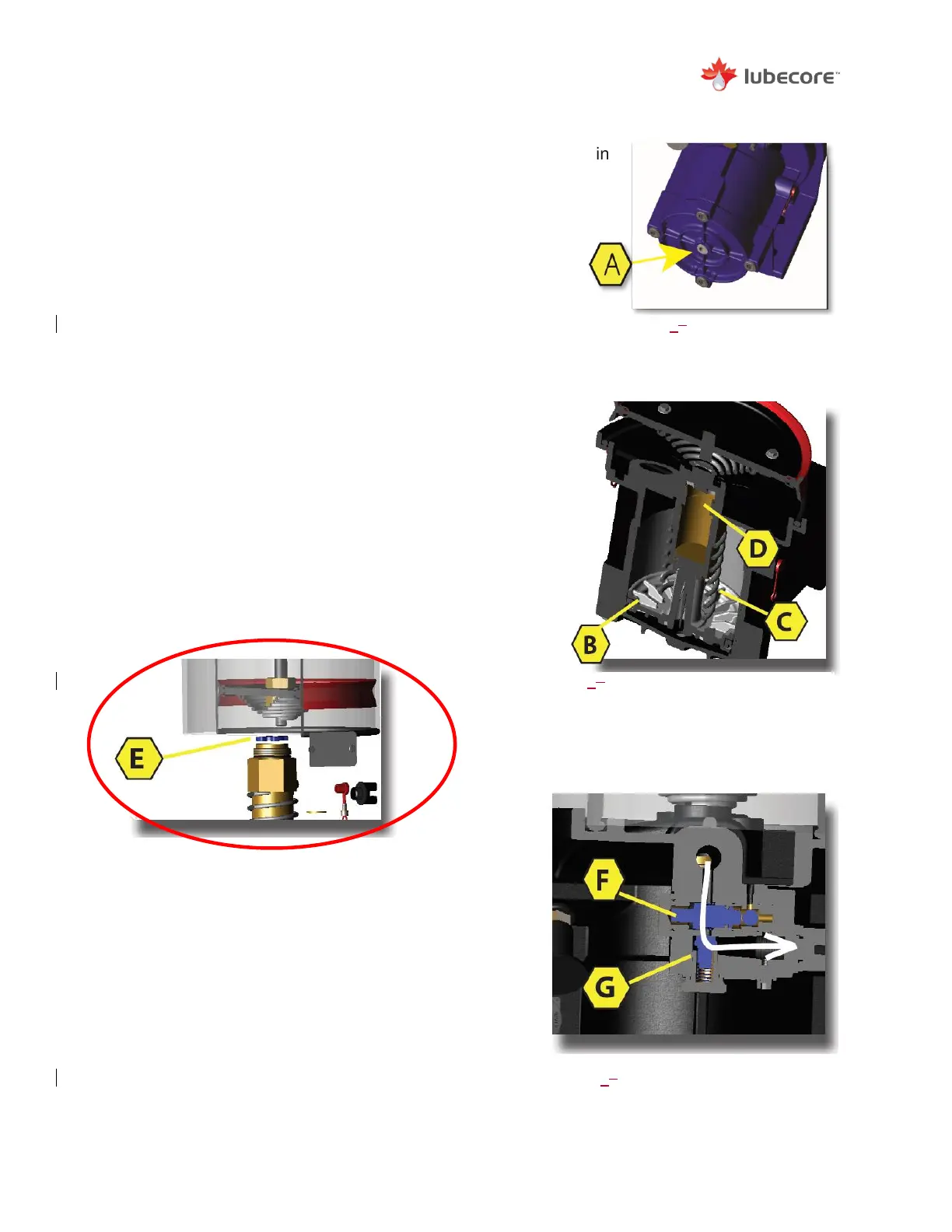

- Air pressure enters the pump via opening (A), as shown in

the illustration on the right, in the bottom of the pneumatic

pump.

o Air pressure requirement; for the pump to

generate a sufficient amount of pressure, is a

minimum of 6 bar (100 psi).

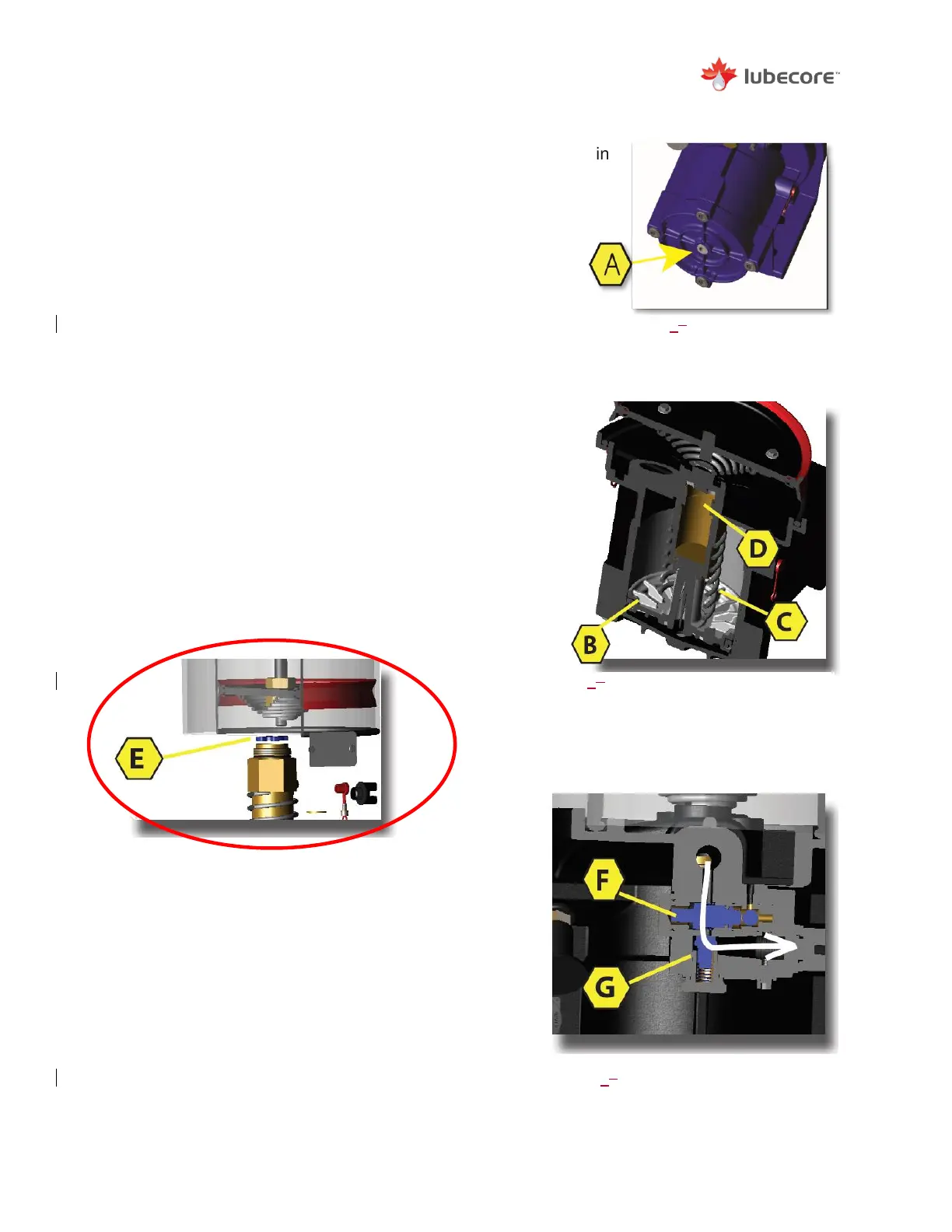

- Air pressure moves piston (B) upward against spring

pressure (C), pushing lubricant into chamber (D). The

flapper valve (E), placed above piston (B), prevents lubricant

displaced by the upward motion of piston (B), from returning

to the lubricant reservoir.

- Piston (B) can create maximum lubricant pressure

at a surface reduction of 10:1. For example, an air

pressure of 100 psi will result in a lubricant pressure of

1000 psi.

- Pressurized lubricant flows from grease camber

(D) by way of internal pump galleries to the mainline

tubing, over the return valve (F) and non-return valve

(G).

- Return valve (F) prevents the lubricant from flowing

to the reservoir. This route is blocked as long as the

grease pressuring from piston (B) is pushing against

the return valve assembly.

Figure 6

Placement of Flapper Valve (E) above Piston (B).

- Non-return valve (G) allows lubricant to flow out

from the return valve (F) to the mainline outlet of the

pump.

- After the completion of the lubrication cycle, air

pressure from under piston (B) is released and

grease pressure drops to zero. Lubricant pressure

is released from the return valve (F), allowing

grease to return to the reservoir via the internal

galleries.

Figure 45

Air Entry Opening (A) in

Bottom of Pump

Figure 56

Cross Sectional View of the Grease

Piston and Return Spring inside the

Pneumatic Pump.

Figure 78

System delivering lubricant

Loading...

Loading...