33

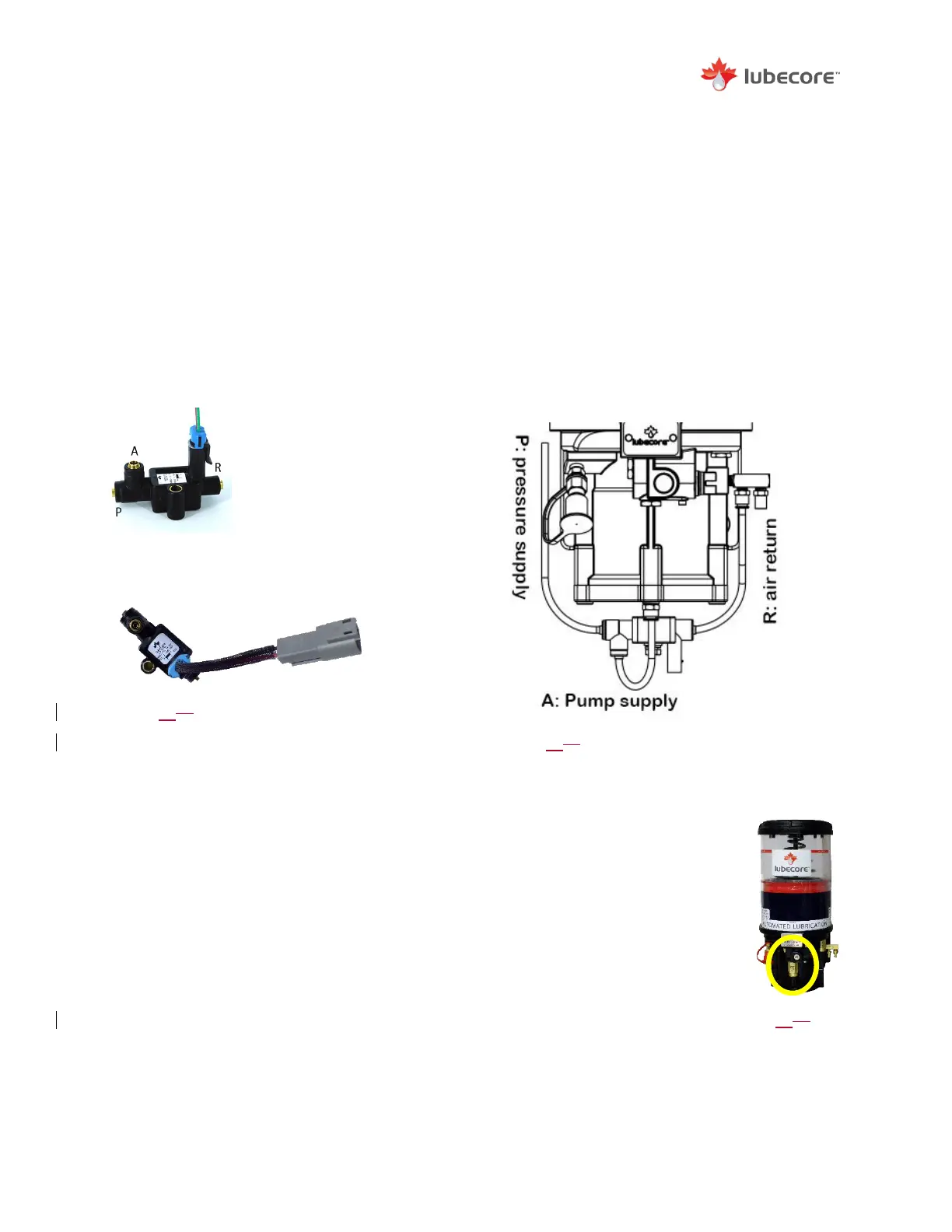

Solenoid Operation

The solenoid is normally located on the bottom of a pneumatically operated pump for truck

applications.

In the non-activated state, the connection between the air tank and the pump is closed. When

activated, air flows from connection (P) of the solenoid to the pump, through opening (A). At the

end of the lubrication cycle, the solenoid valve returns to its original position closing the

connection between air tank (P) and pump (A). In this neutral position, the solenoid opens port

(A) to port (R) allowing air to flow from below to above the grease piston. Replenishing the

vacuum above the piston with air from below, held to a constant 5 psi via the air vent check

valve, prevents contaminants and moisture from entering the pump.

Before Sept 2019

After Sept 2019

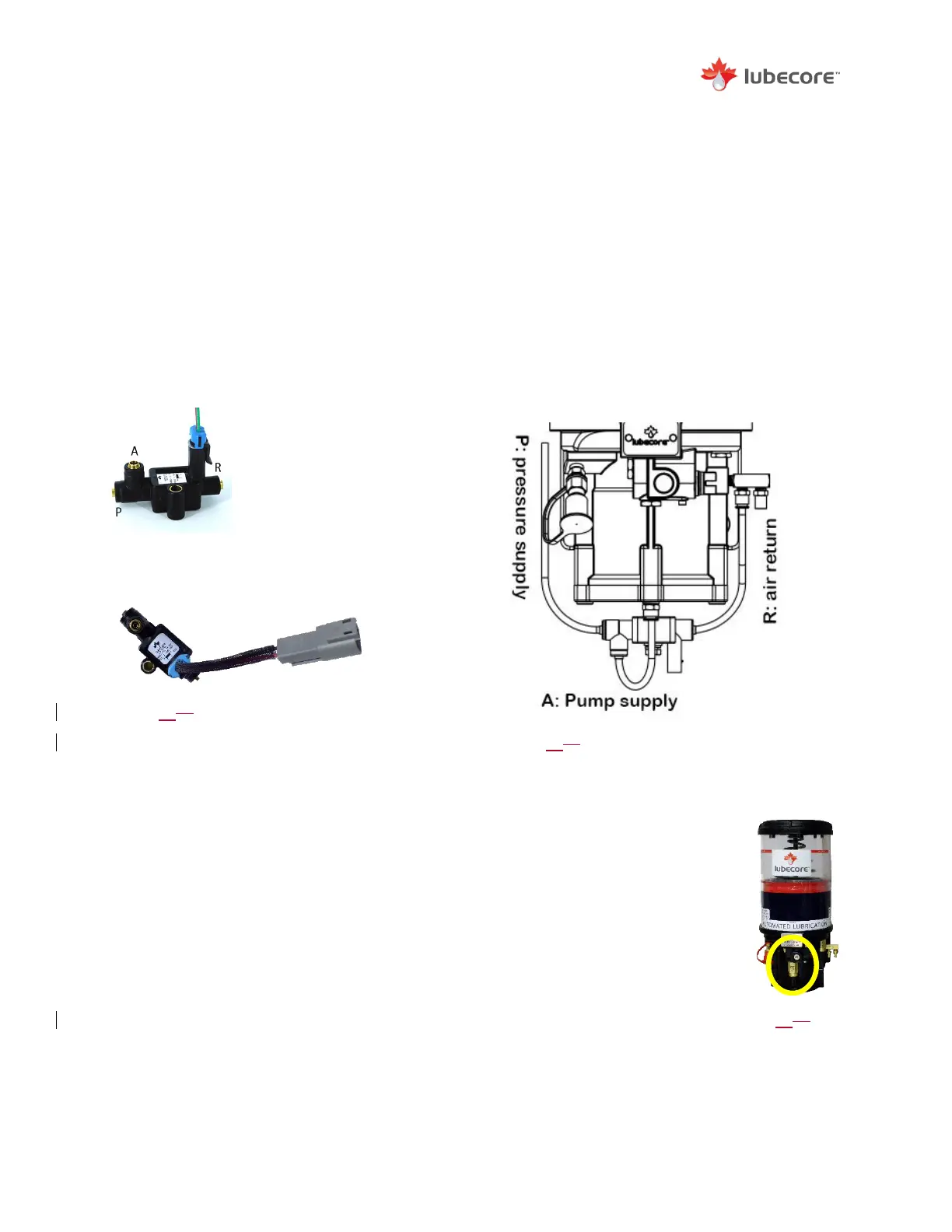

Pressure Switch

A standard Lubecore automated lubrication system is equipped with a pressure

switch. Once the lubrication system has reached nominal operating pressure,

the pressure switch provides feedback to the timer. The pressure switch is, for a

pneumatically operated pump usually located in the front- center of the pump.

Pressure switches can also be located in manifold assemblies.

When a pressure alarm occurs, the operator is informed by an audible alarm

from the timer and when installed, a visual alarm. This visual alarm is usually a

green dash mounted LED identified by a Lubecore label.

Figure 2830

Lubecore air solenoid

Figure 2729

Air solenoid Schematic

Figure 2931

Pneumatic

pump pressure

switch location

Loading...

Loading...