RD 500 E

EN

www.magmaweld.com

18

USER MANUAL | KULLANIM KILAVUZU

3.2 Welding

3.2.1 Welding Mode

3.2.2 Carbon Gouging Mode

3.2.3 Remote Control (Optional)

• Push the welding/carbon gouging selection button (11) for selecting the welding mode. Welding LED (14) lights.

• Select the type of the electrode to be used via the selection button (10). Select the rutile/basic)aluminium electrode mode for rutile, basic or

aluminium electrodes. Select the cellulosic electrode mode for cellulosic electrodes.

• Adjust the current cia current adjustment knob (5).

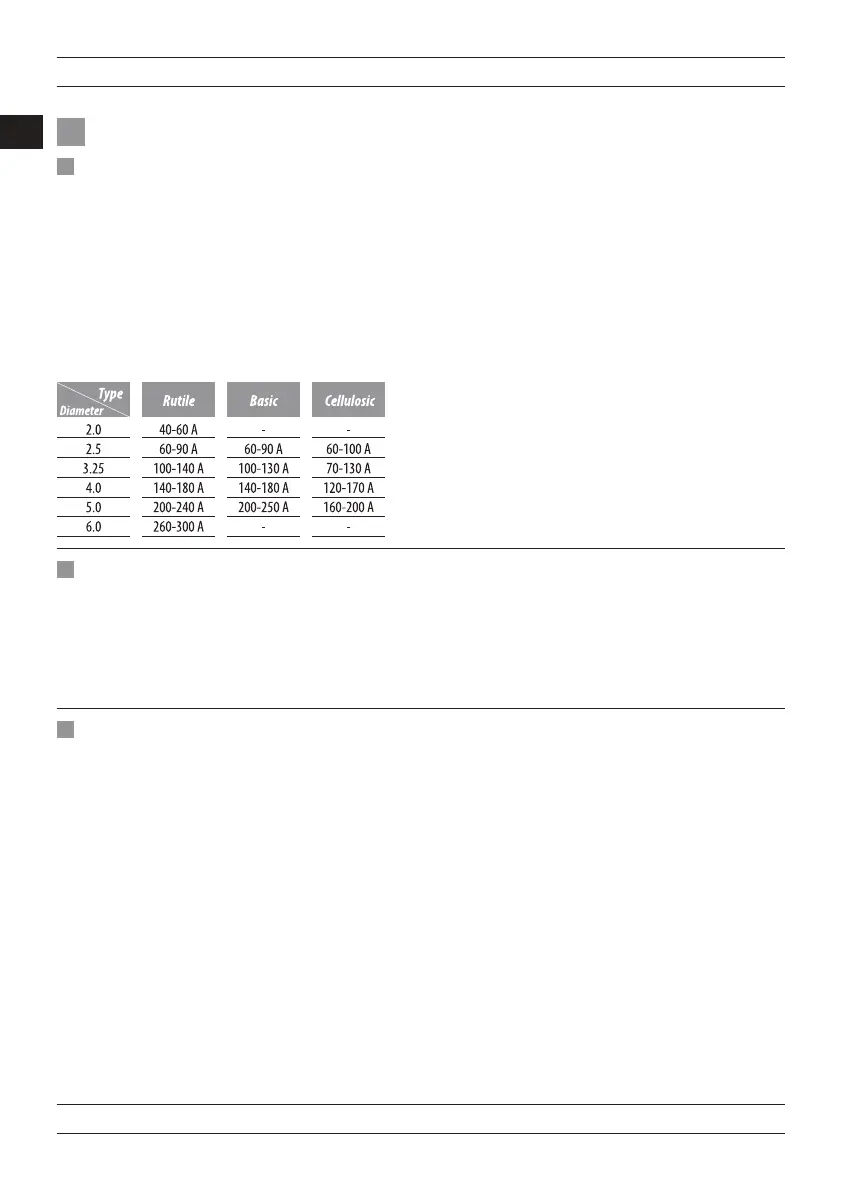

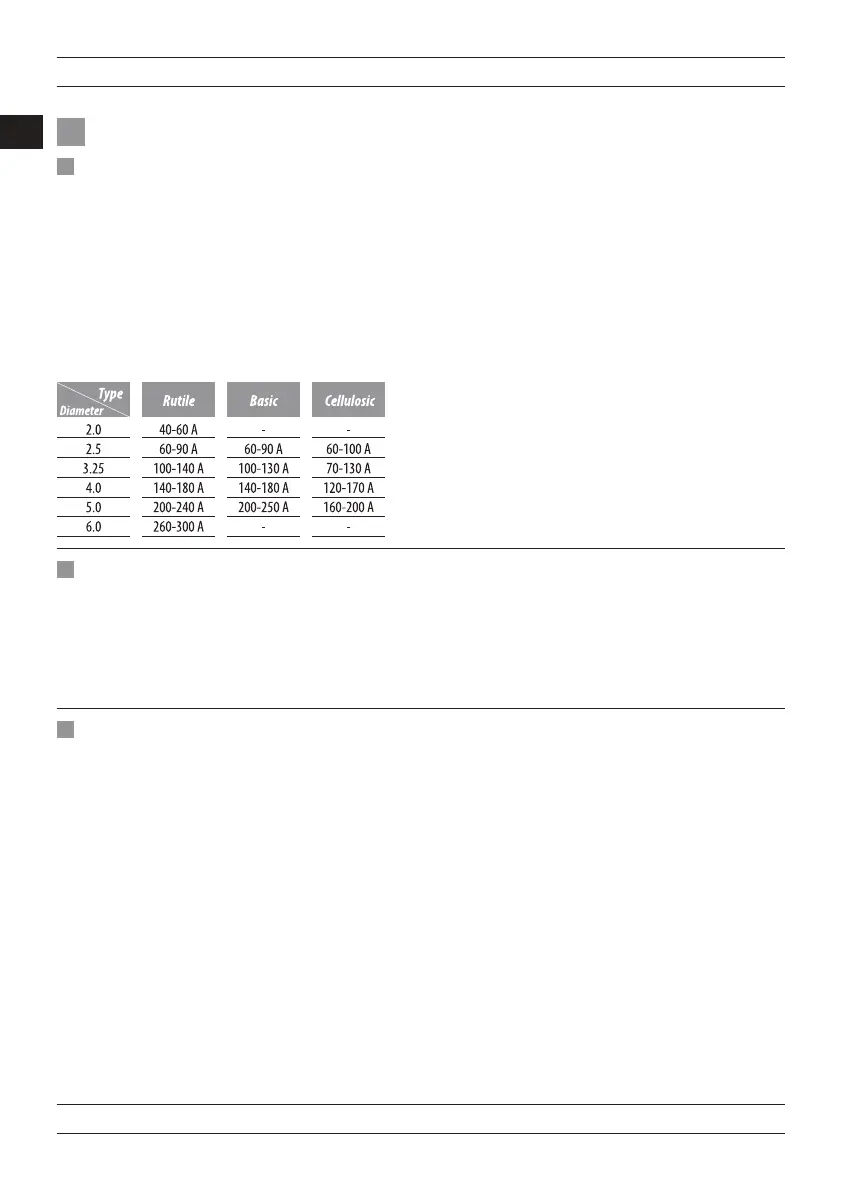

• Below table can be used as a rough reference for mild steel electrodes. For exact parameters, please refer to the electrode manufacturer’s recommen-

dations.

• For better ignition turn the HOT START knob (8) clock-wise. Welding arc can drill the metal when it is very thin and HOT START is high.

• ARC FORCE is useful for electrodes which have tendency to stick into the weld pool during welding. Turning the knob (9) clock-wise will decrease

the tendency to stick. If ARC FORCE is adjusted too high, spatter increases.

• Start welding. You can observe welding current (A) and voltage (V) by current display (6) and voltage display (7).

• Push the welding mode selection button (11) for selecting the carbon gouging mode. Carbon gouging LED (15) lights.

• Adjust the current via current adjustment knob (5).

• For better ignition turn the HOT START knob (8) clock-wise. Welding arc can drill the metal when it is very thin and HOT STARTS is high.

• ARC FORCE is useful for electrodes which have tendency to stick into the weld pool during welding. Turning the knob (9) clock-wise will decrease

the tendency to stick. If ARC FORCE is adjusted too high, spatter increases.

• Start carbon gouging. You can observe welding current (A) and voltage (V) by curren display (6) and voltage display (7).

• It is possible to connect wireless or cable remote control unit. In this case, appropriate control socket must be installed onto the back cover by

a certified Magma Service.

• When the remote control connector is connected to the machine, ampere adjustment knob on the machine is disabled automatically and current

adjustment is made by the remote control.

Operation

Loading...

Loading...