M

Michael HughesAug 8, 2025

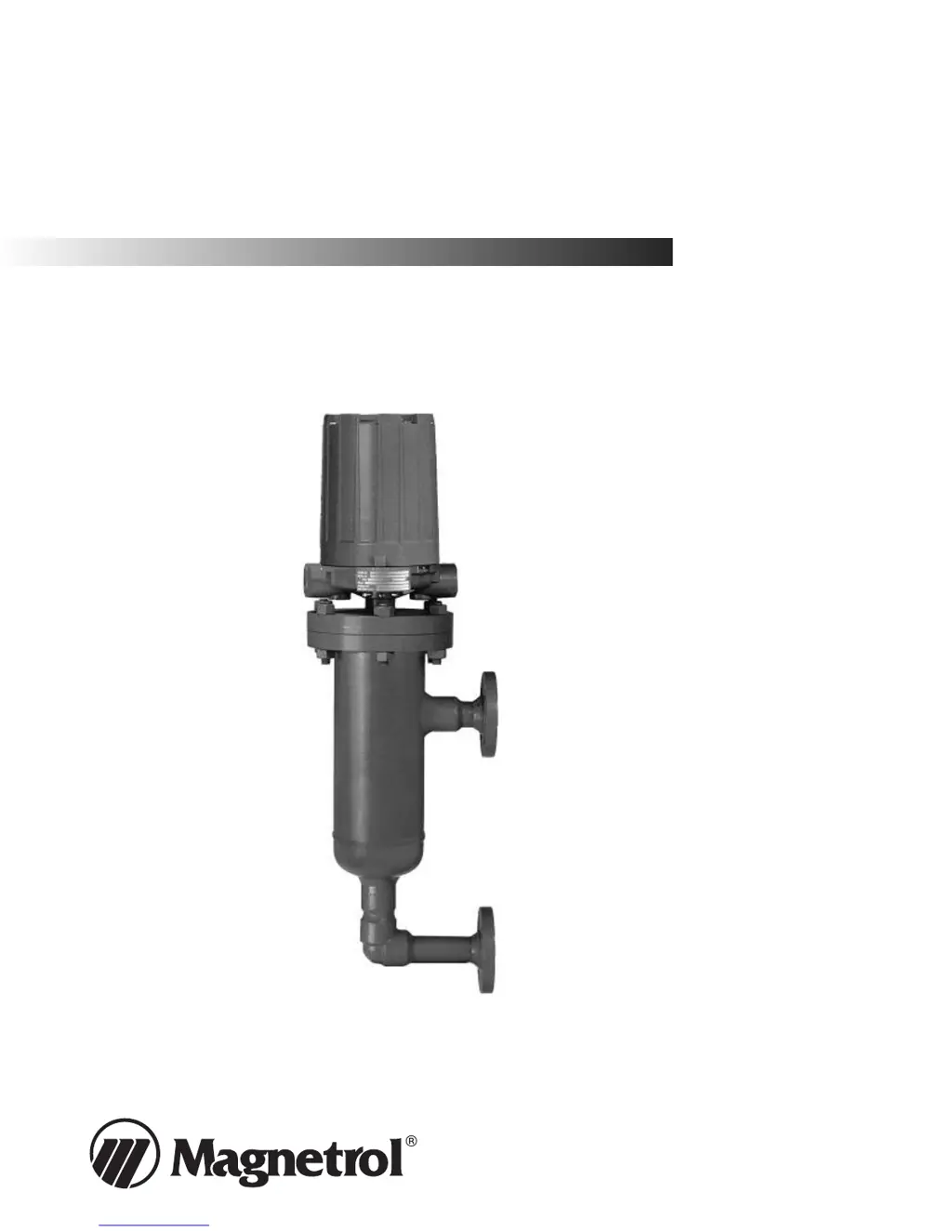

How to troubleshoot a Magnetrol B60 Switch when the pump won't start?

- CCarrie KochAug 8, 2025

If the pump won't start or stop, or the signal lamps fail to light, check the fuses, reset button(s), power switch, controlled equipment, and wiring.