5

6

7

8

Removing and installing crankshaft

103

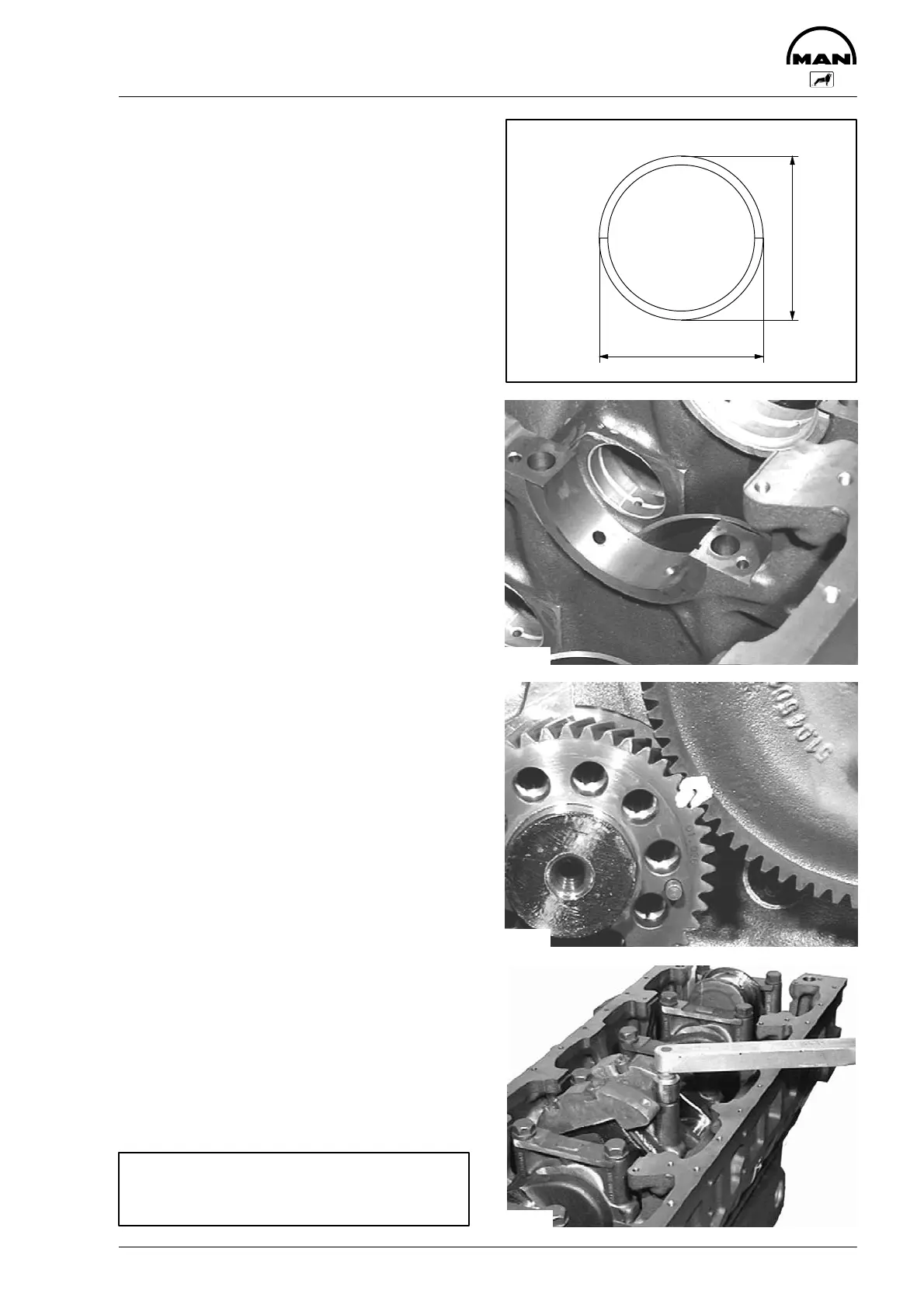

Checking spread of bearing shells

Fig. 5

Position bearing shells together on flat surface.

Measure and note down spread dimensions ”A”

and ”B”.

Spread dimension = A – B

Installing crankshaft

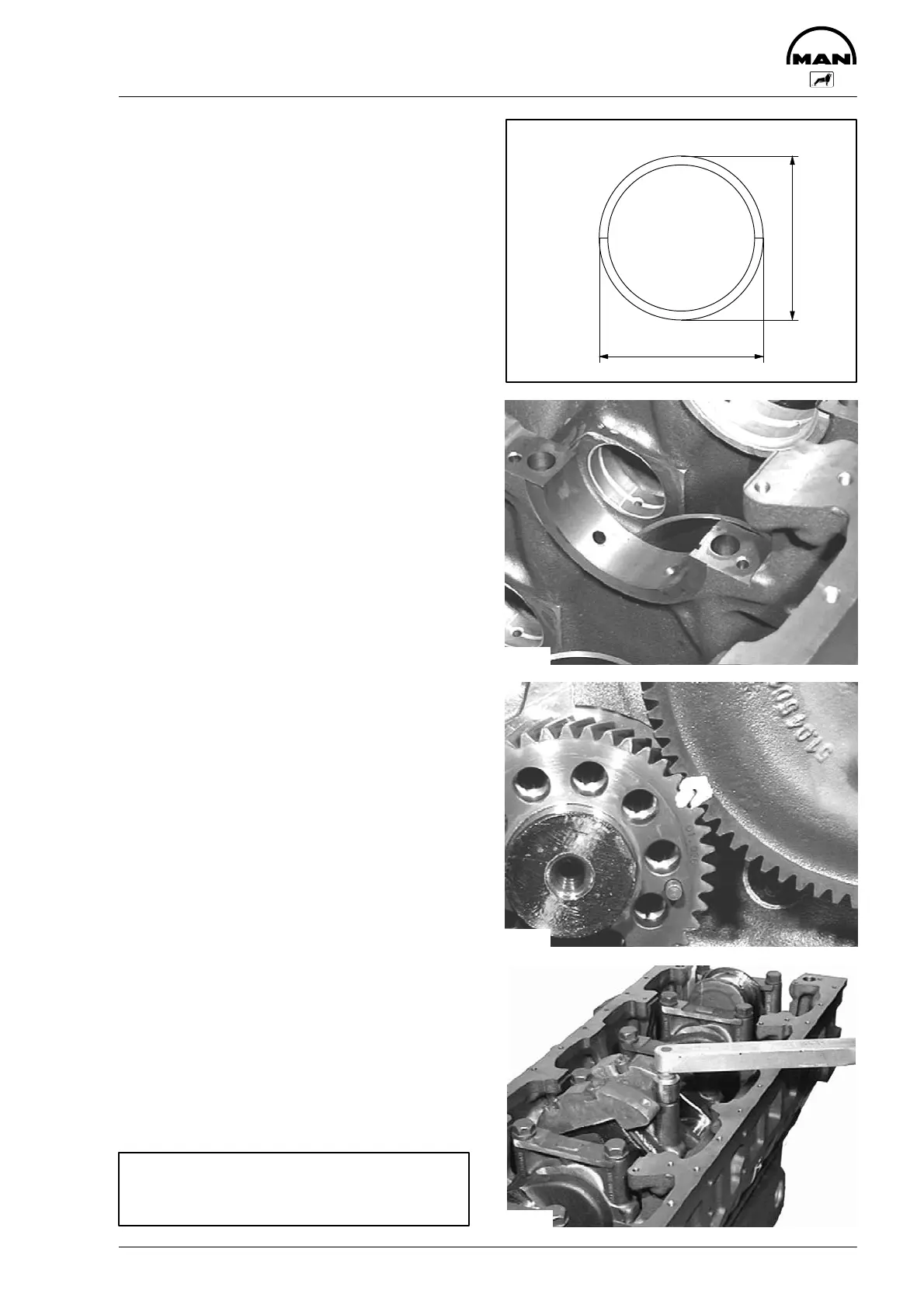

Fig. 6

Clean oil ducts in crankcase and in crankshaft with

dry compressed air.

Thoroughly clean bearing shells and bearing

journals.

Install bearing shells in crankcase, observing the

numbering.

Fig. 7

Apply oil to the running surfaces on the bearing

shells and install crankcase, ensuring that the

markings on the crankshaft and camshaft gears

coincide.

Fig. 8

Check whether the bearing cap bolts have ex-

ceeded the max. permissible length (see ”Engi-

neering, data and setting values”). Bolts that have

been removed may be reused if the max. permissi-

ble length is not exceeded.

Insert bearing cap screws and tighten to specified

torque in stages from the inside out (see ”Engi-

neering, Data, Setting values”).

Tighten finally by angle.

Check to see that crankshaft runs smoothly.

Important:

Faulty bearing caps cannot be replaced

singly.

2376

A

B

3543

3545

3551

Loading...

Loading...