Commissioning

54

Carefully read the Assembly Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

6.3 Commissioning Exhaust System

6.3.1 Measuring Exhaust Back Pressure

The exhaust back pressure must be measured

during commissioning.

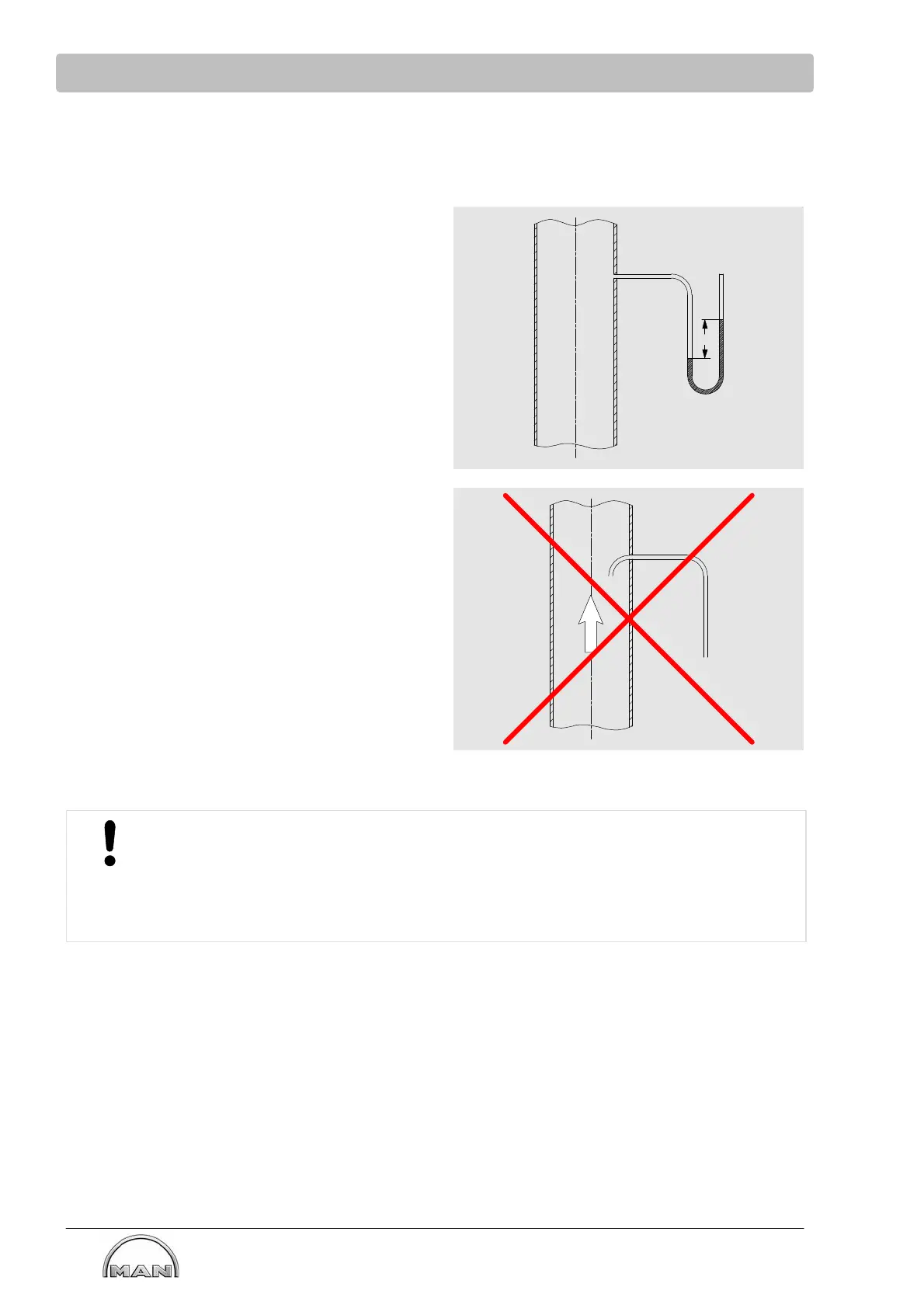

The measuring point of the exhaust back pressure

(threads e.g. M14x1.5) must be selected in a

straight part of the exhaust pipe.

Measurements take directly downstream of the

turbocharger will have distorted results by approx.

20 mbar.

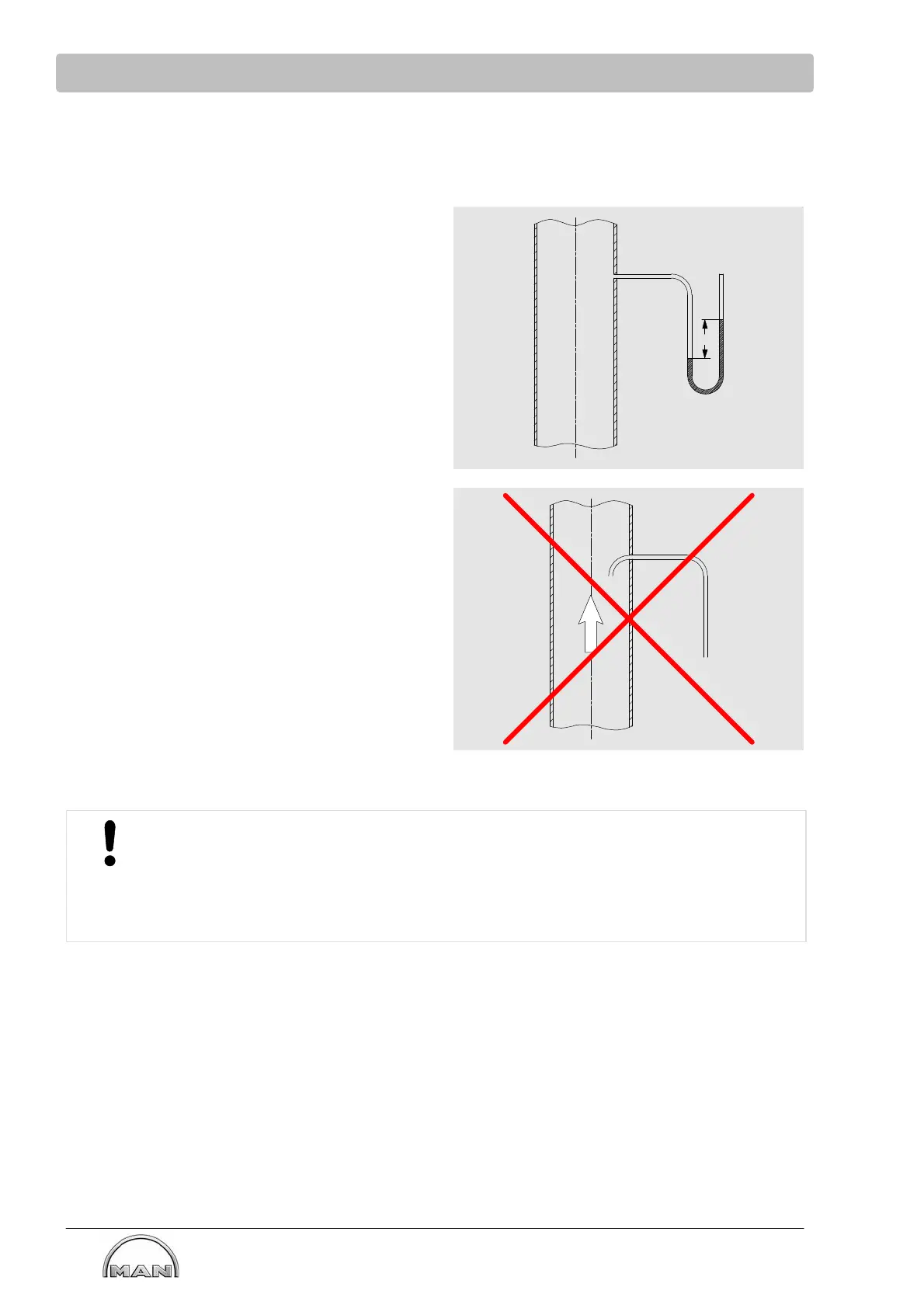

The static pressure is measured, i.e. the

measuring connection must be flush with the inner

pipe walls.

Measurement of the head pressure and

measurements taking in bends will created

incorrect results.

The engine is to be operated at full power and

rated speed during the measurement.

The simplest measuring instrument is a slack tube

pressure gauge filled with water

(1 hPa = 10 mm Ws)

Ø 3 mm

H

6.3.2 Measuring Exhaust Temperature

IMPORTANT!

The max. permissible exhaust temperatures are specified in the installation instructions.

Excessive exhaust temperatures lead to serious engine damage.

For this reason:

S Continuous monitoring of the exhaust back pressure is mandatory.

Loading...

Loading...