22 ECM | 1.01.00 www.mc-techgroup.com

17.2 CHANGING THE TEMPERATURE ALARM RANGE

The exact description of how to change the temperature alarm range, can be found in the the

temperature controller manual.

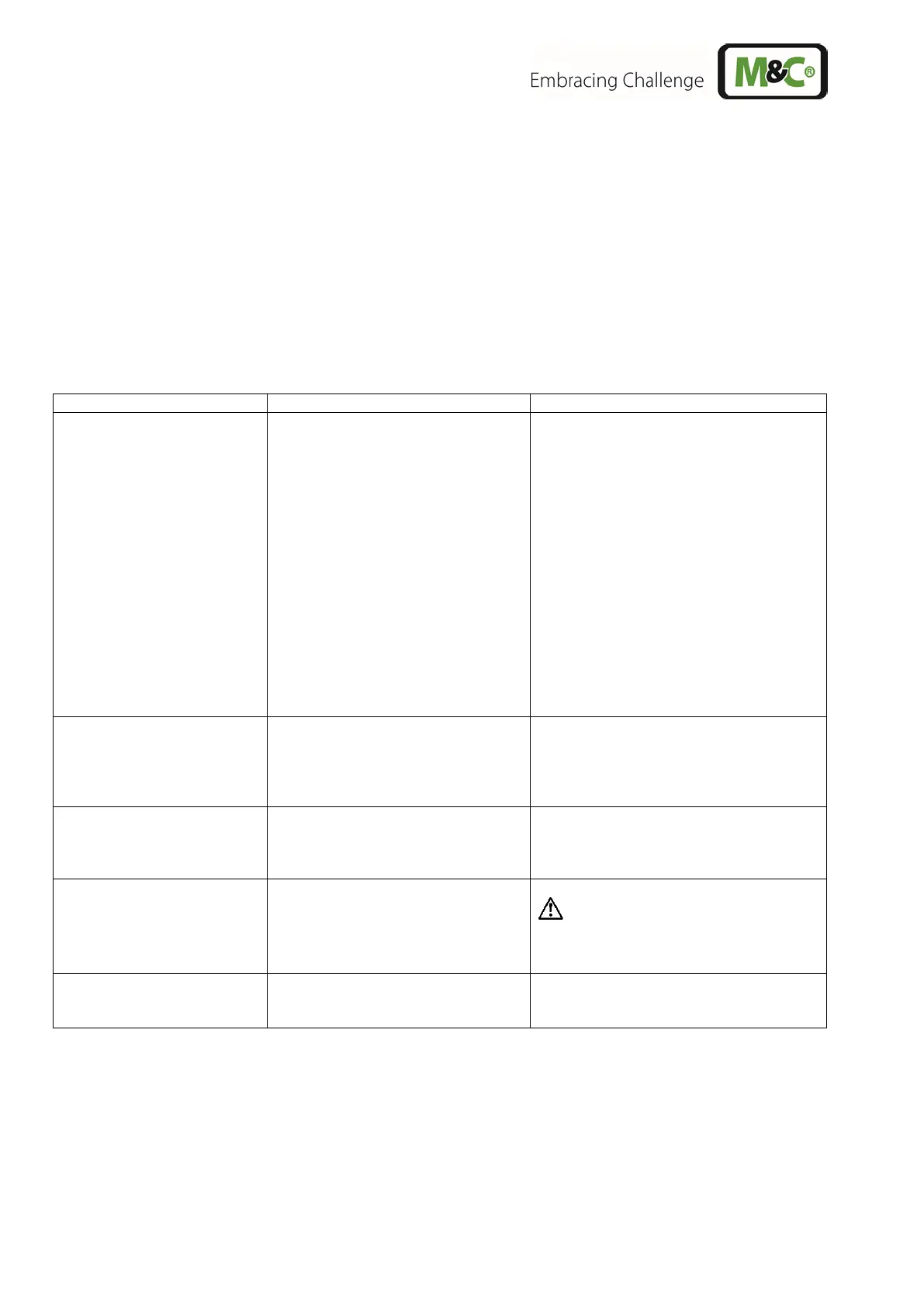

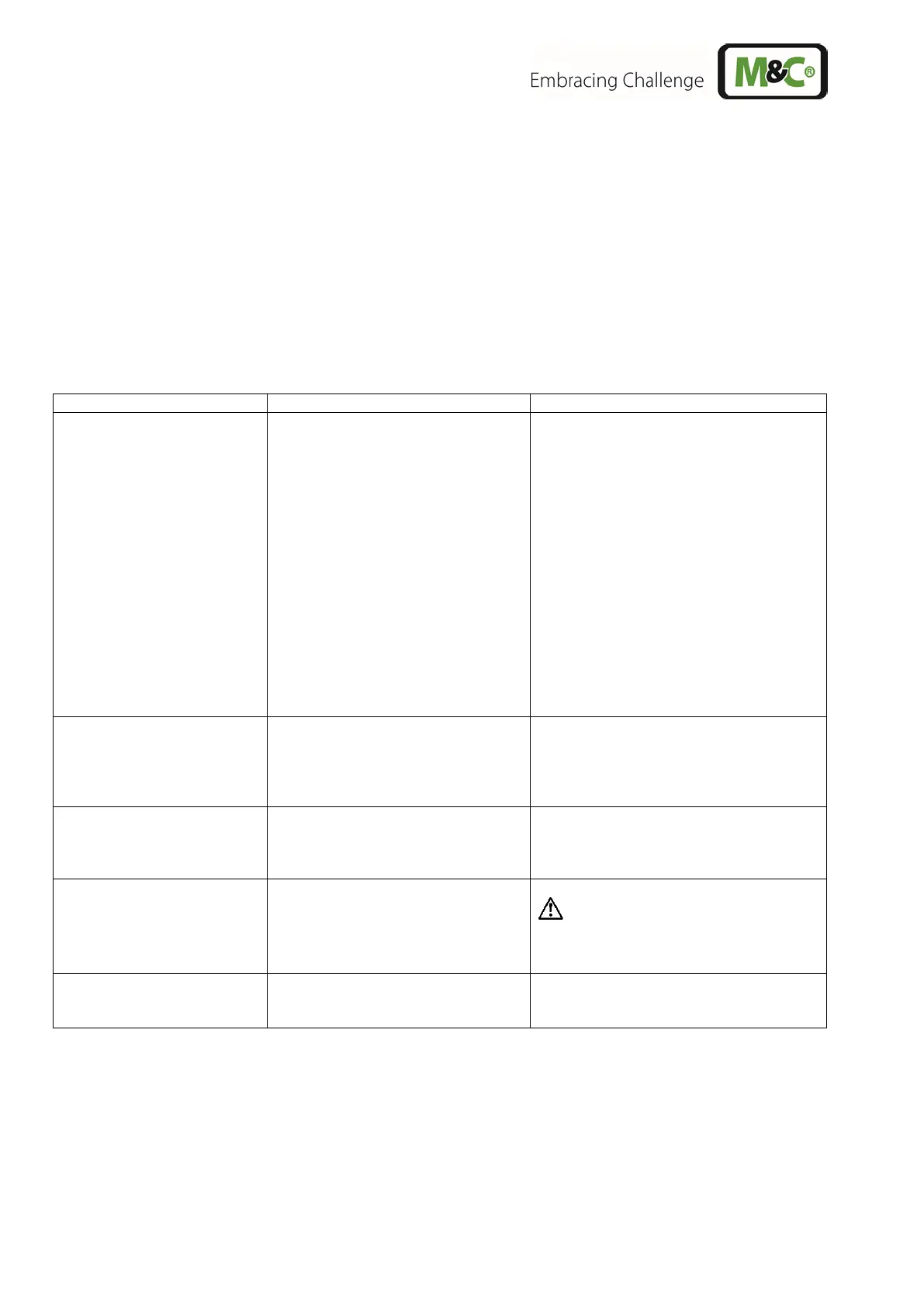

18 TROUBLE SHOOTING

The following table shows a list of possible errors and instructions how to check and to repair them (this

is not valid for the starting-up period of the cooler).

Condensate in the gas outlet

Ambient temperature < 5 C [41 °F]

Cooler overloaded

Peristaltic pump doesn’t work

Tube of the peristaltic pump

defective

Cooling capacity too low

(cooler is not overloaded)

Motor protection switch released

Heat up the components downstream;

Keep the operational data (10.);

Change peristaltic pump;

Change the tubing (18.3);

Clean the fins of the condenser (18.2);

Check the vent;

Check the safety distance to other

heated components;

Secure sufficient ventilation;

Thermal load caused by the sample gas

resp. ambient is too high;

Clean the fins of the condenser;

Keep the operational data (10.);

Let the cooler cool down before

restarting it;

Gas flow blocks up reading

Contamination of the sample gas

way

Optimize the dust pre-separation

upstream the cooler;

Clean the gas ways and the cooling

system;

Temperature sensor defective

Temperature controller defective

Circuit of cooling agent leaky

Check the PT100-sensor;

Check the temperature controller;

Send the cooler for repair;

Check the power supply and reconnect;

Pay attention to the relevant

safety instructions!

Compressor defective;

Motor protection switch defective

Send the cooler for repair;

Loading...

Loading...