PREVENTIVE MAINTENANCE PROCEDURE

CHALLENGER Series II Bulletin No. IX8

Maintenance Point

Frequency Interval

Procedure Information

Clean away old grease from the inside of the “U” shaped registration forks and each of the registration cam follower

bearings on the index table. Use a small painters brush to apply a fresh coat of white lithium grease (M&R Part No.

7018017) to the inside of the “U” shaped registration forks and around the outer race of each registration cam follower

bearing.

Monthly

Tools required:1 - M&R Part No. 7018017 White Lithium

Grease

1 - Small Painter’s Brush

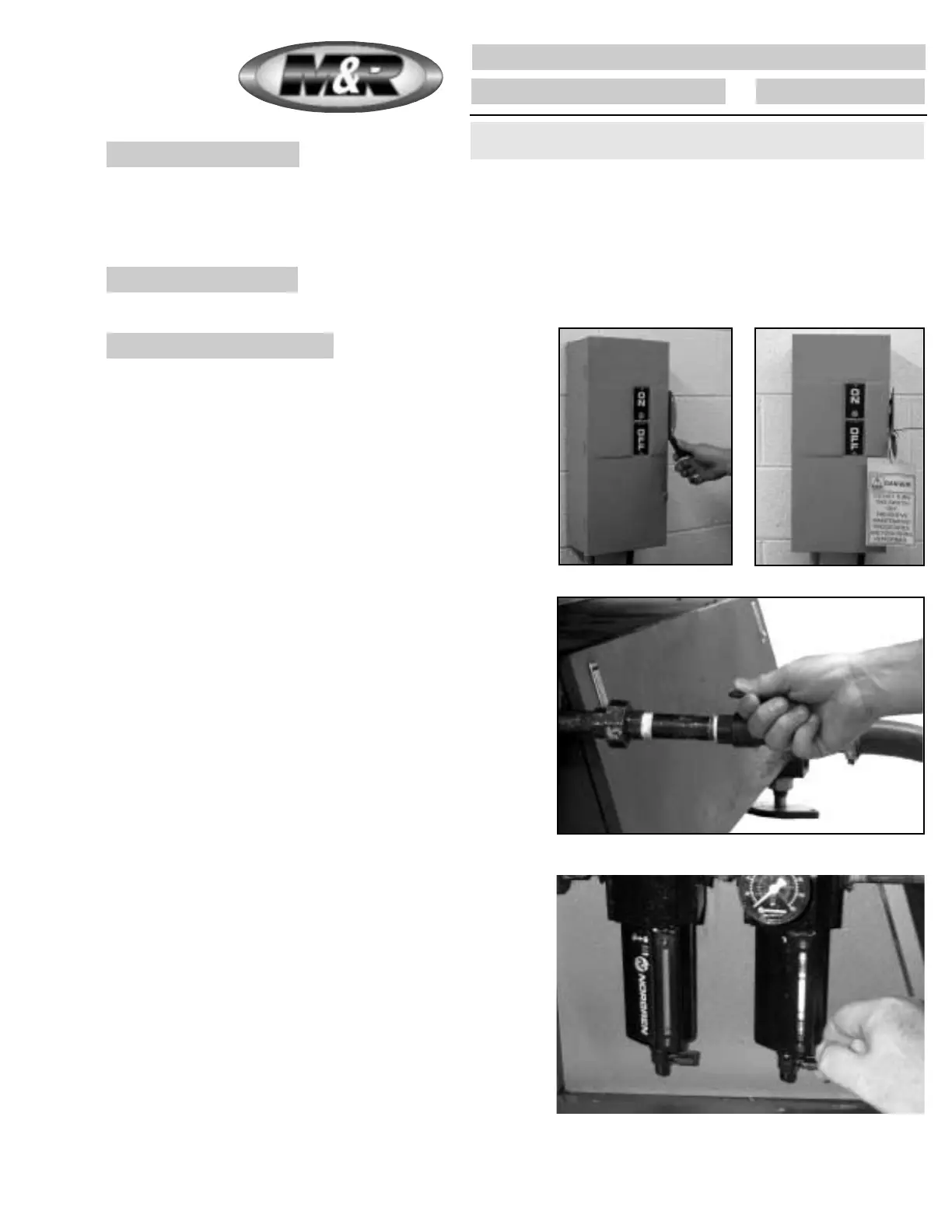

1. Disconnect, lock out and tag the electrical and pneumatic

power from the equipment.

2. Disconnect the compressed air supply from the equip-

ment by closing the manual shut-off valve. The manual shut-

off valve is closed when the handle is positioned across the

air supply pipe/hose. (See illustration at right)

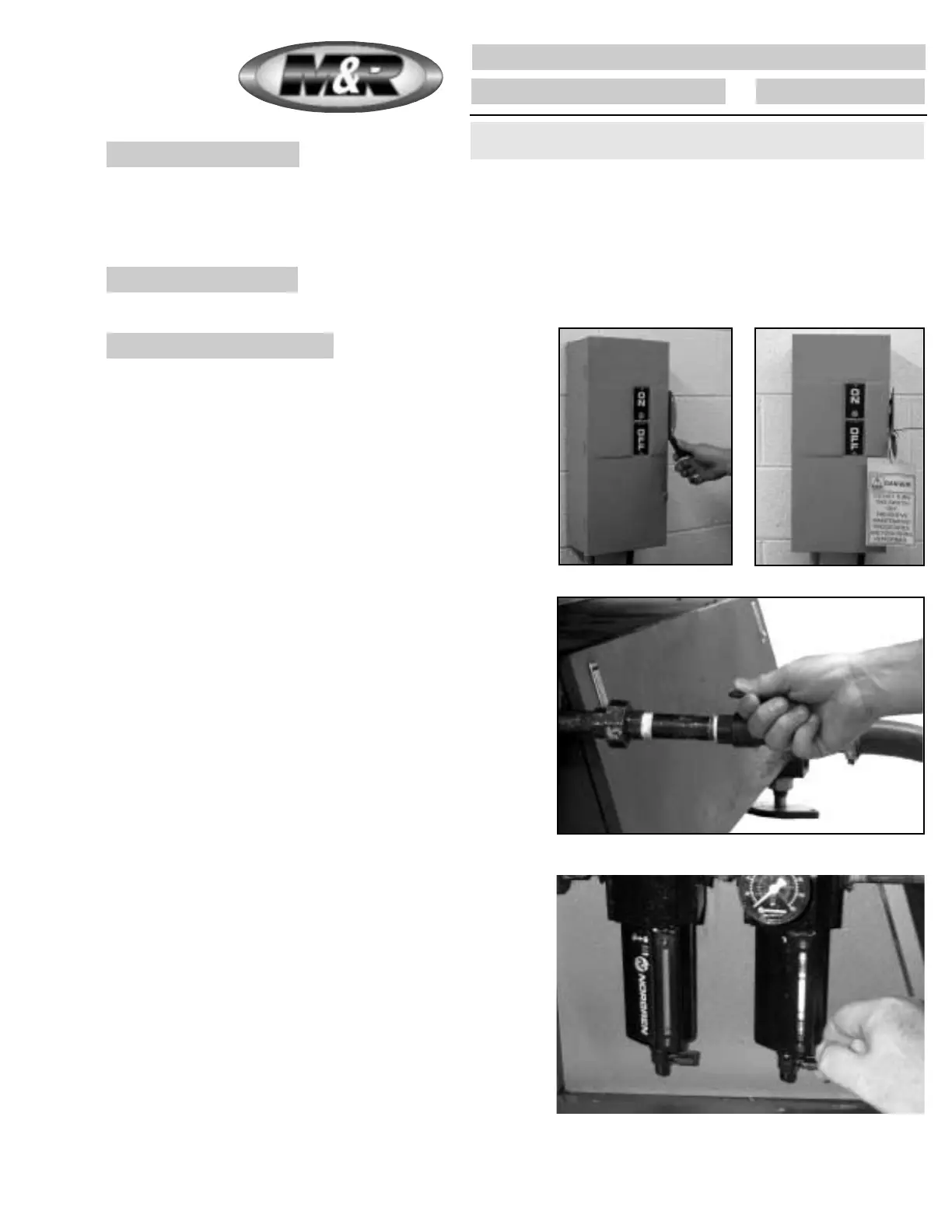

3. Bleed off any compressed air which may remain in the

system by opening the small pet-cock valve (turn handle

counterclockwise to open valve) at the bottom of the mois-

ture trap assembly. Allow any compressed air to completely

evacuate the system before closing (turn handle clockwise to

close) the pet-cock valve.

081200MS

93

The frequency of the following preventive maintenance procedure is

based on a 8 hour daily production shift or 40 hour work week.

Loading...

Loading...