Installation

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

13

The M&R Challenger Series II requires installation by an

M&R factory-trained service representative. The following

conditions must be addressed before a technician can be

scheduled for your installation.

Pre-Technician Checklist for Challenger II Installation:

• Uncrate your Challenger II and check for

any obvious damage.

• Using the Chart on page 5 or 6, determine

the space requirements for your

Challenger II. Position the base in the

center of this area.

• Have the compressor and dryer (chiller

unit) operational. Use 3/4" black pipe from

the compressor to press with a Shut-Off

Valve provided at the press.

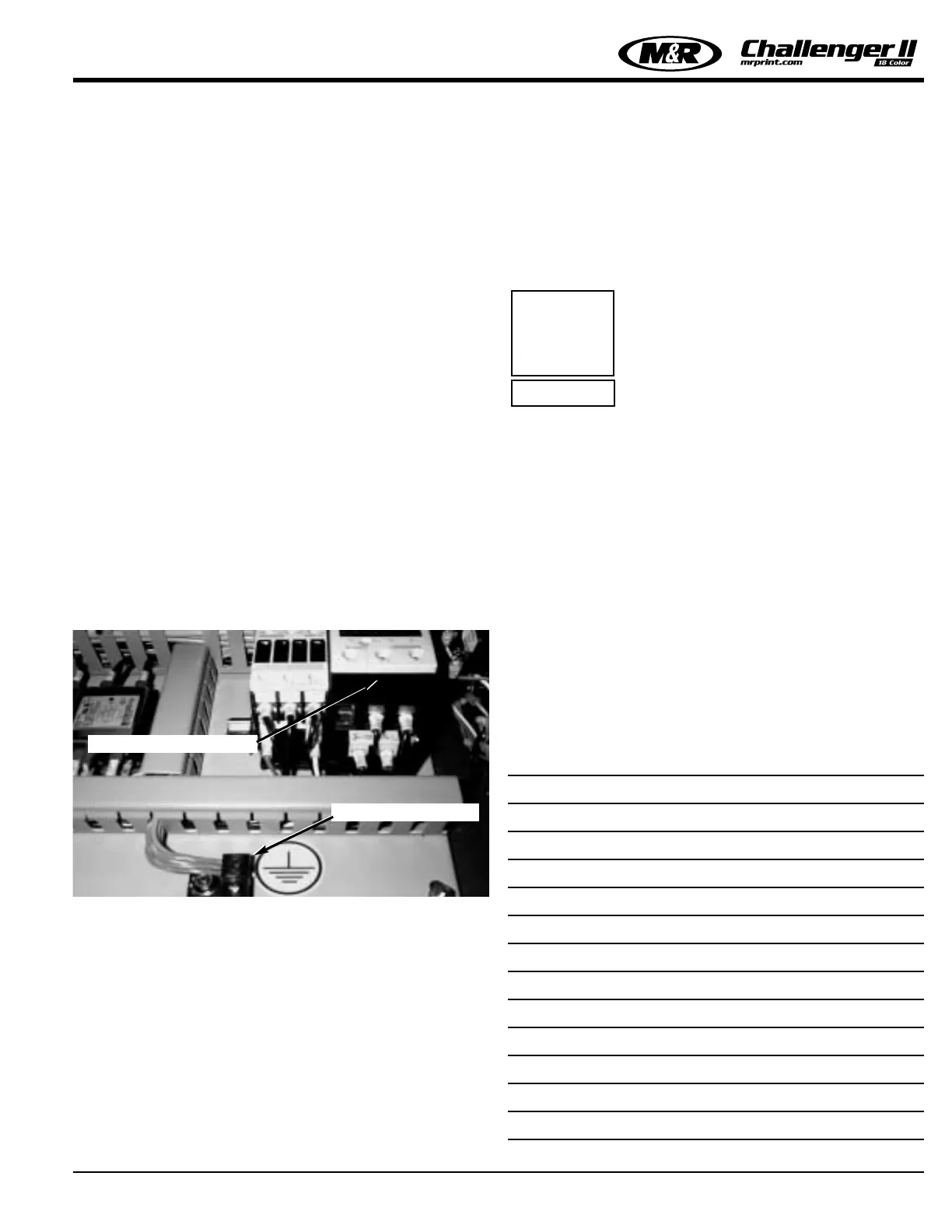

• Refer to the Manuafacureres Rating Plate

mounted to the control panel. Install the

required Electrical Service at the power

input contactor located inthe electrical

enclosure on the indexer base assembly.

Do not connect to press at this time.

(See illustration below)

• If optional flash cure is to be used, install

the electrical service as indicated on the

Manufacturer’s Rating Plate at all the

positions where it might be used. Refer to

the Manufacturer’s Rating Plate on each

flash cure unit for specific electrical

requirements.

• Provide one 16", squeegee blade ready to

install at every station (size 1 7/8" x 3/8").

Please note, squeegee blades are not

provided with your press.

• A three-color minimum print job, with tight

registration, should be ready to run. Refer

to page 11 & 12 for the required screen

frame dimensions and image placement.

• Provide adequate assistance (labor) for the

M&R technician during the assembly.

NOTE: Grease and oil are shipped with all

new M&R Challenger Series II presses.

• Provide a grease gun with standard Zerk

fitting. Fill the grease gun with white

lithium grease. Have another grease gun

filled with Synthetic Teflon Grease. One

quart of 10W non-detergent oil also will be

required.

After assembling, completing registration and checking

general operation of the Challenger Series II, our Service

Representative will assist your production staff in setting up

a job for which you have screens prepared. He will super-

vise and instruct all designated personnel in the proper pro-

duction procedures. This includes instructions on the cor-

rect usage of controls and preventive maintenance

described in the following sections of this manual.

i

IMPORTANT!

NOTES:

Electrical Input Contactor

Earth Ground Terminal

Loading...

Loading...