PREVENTIVE MAINTENANCE PROCEDURE

CHALLENGER Series II Bulletin No. PH6

Maintenance Point

Frequency Interval

Procedure Information

Lubricate the micro-registration threaded adjustment shafts on each print stations front and rear screen frame holder

assembly.

Every Three Months

Tools required:1 - M&R Part No. 7018017 White Lithium

Grease

1 - 1 small painters brush

1. Use a suitable wiper or cloth shop towel to remove any old

grease or dirt which may have accumulated on the threaded

shaft surfaces.

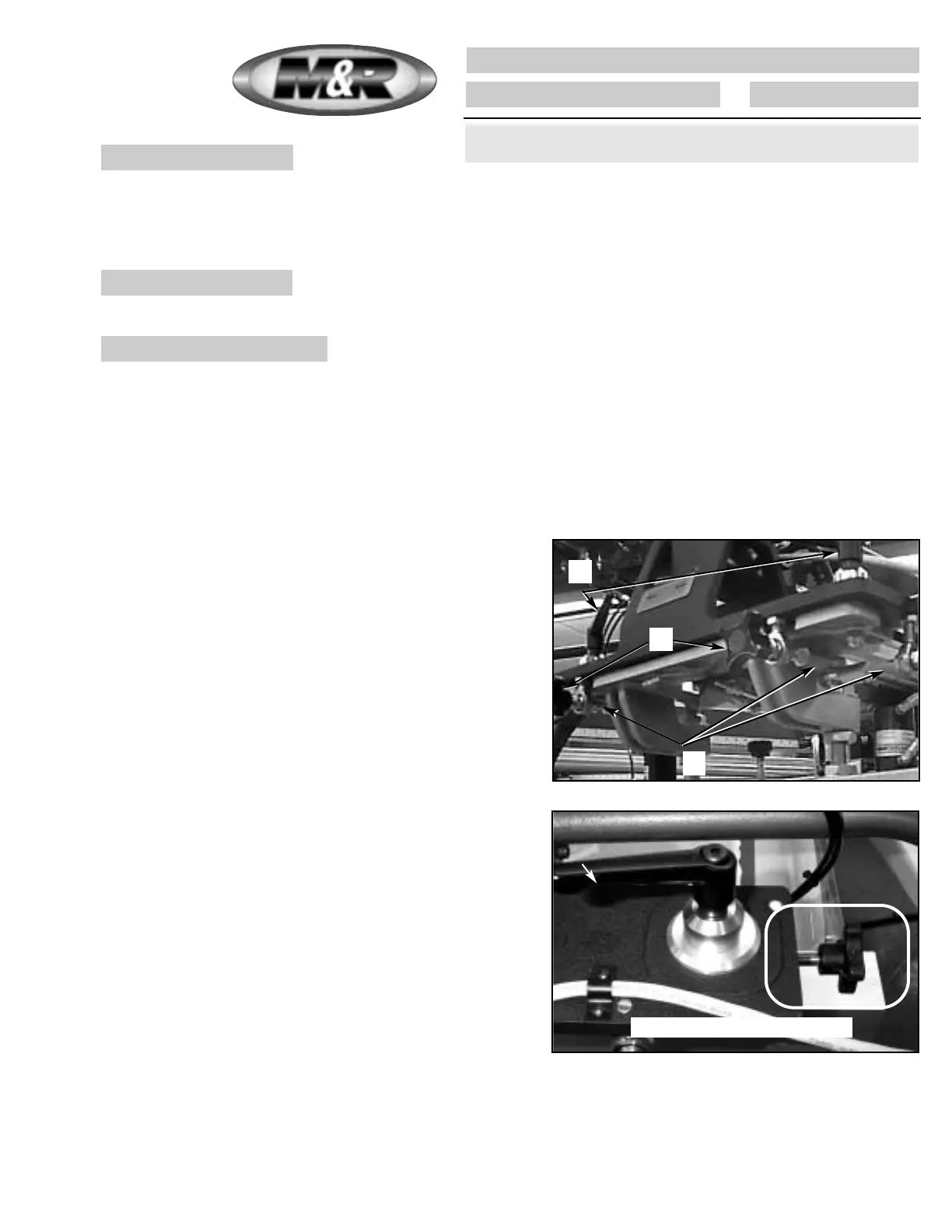

2. First, release the micro-registration locking knobs (a) by

turning counterclockwise. Back out the micro-registration

adjustments (b) fully by turning the adjustment knob coun-

terclockwise. Now, apply a coat of grease to the threads of

the micro register knobs. Turn the micro-registration adjust-

ment knobs (b) clockwise until the micro adjustment refer-

ence pointer registers in the center of the micro-registration

reference grid. Lock the micro-registration lock knobs by

turning clockwise. Using a small painters brush, apply white

lithium grease along the entire threaded shaft (c) for each

micro-registration adjustment on each print station. Do not

apply excessive amounts of grease to the threaded shaft.

Only a small amount is required.(See illustration at right)

Threaded shafts

a.

c.

b.

081200MS

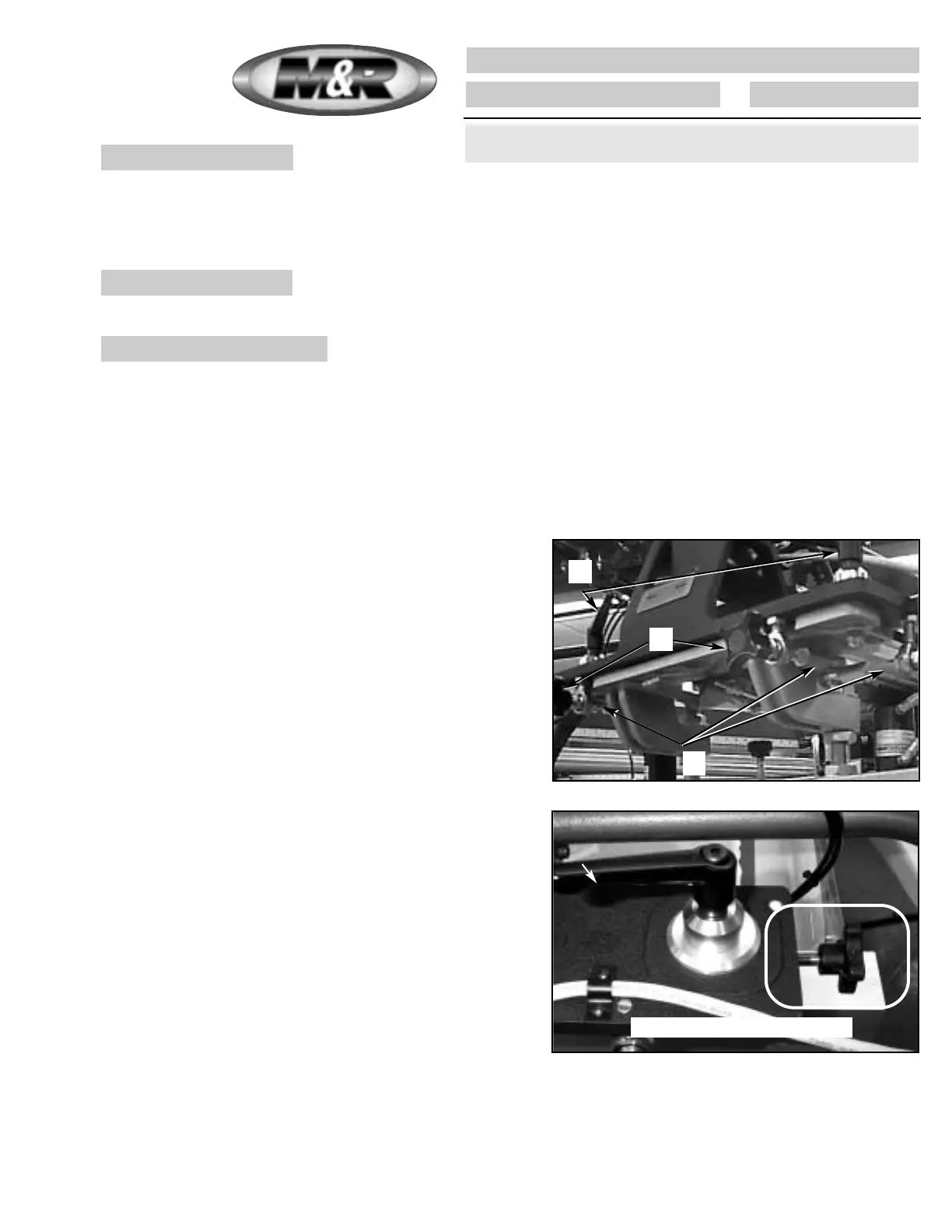

Right to Left Micro Adjustment

95

The frequency of the following preventive maintenance procedure is

based on a 8 hour daily production shift or 40 hour work week.

Loading...

Loading...