081200MS

PREVENTIVE MAINTENANCE PROCEDURE

CHALLENGER Series II Bulletin No. IX2

Maintenance Point

Frequency Interval

Procedure Information

Lubricate indexer assembly bearing using Permatex Super Lube with Teflon. (M&R Part No. 7018031)

Every Day

Tools required:1 - Permatex Super Lube M&R Part No.

7018031

1 - Standard pump action grease gun.

1. Disconnect, lock out and tag the electrical and pneumatic

power from the equipment.

2. Disconnect the compressed air supply from the equip-

ment by closing the manual shut-off valve. The manual shut-

off valve is closed when the handle is positioned across the

air supply pipe/hose. (See illustration at right)

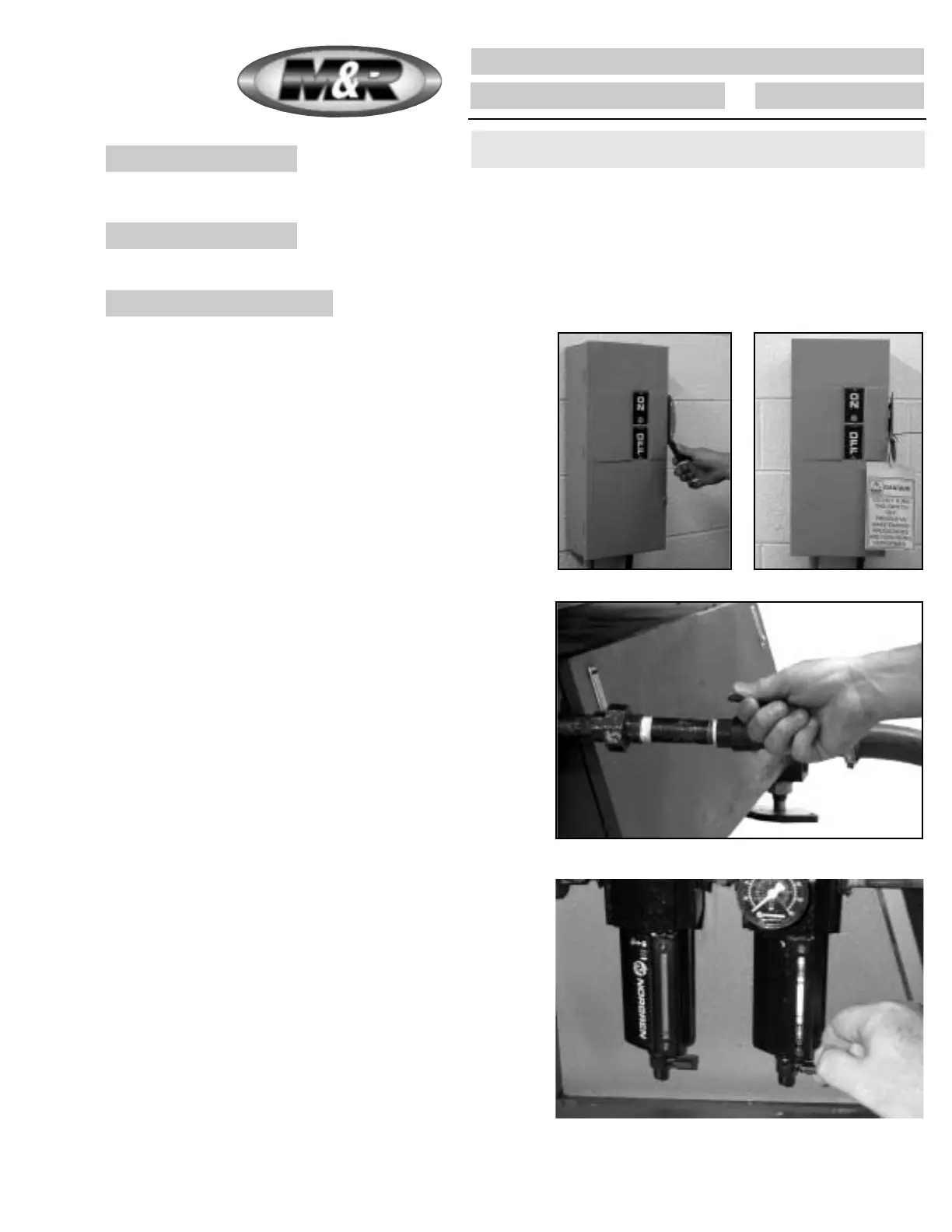

3. Bleed off any compressed air which may remain in the

system by opening the small pet-cock valve (turn handle

counterclockwise to open valve) at the bottom of the mois-

ture trap assembly. Allow any compressed air to completely

evacuate the system, the needle on the air gauge should

read zero, before closing (turn handle clockwise to close) the

pet-cock valve.

71

The frequency of the following preventive maintenance procedure is

based on a 8 hour daily production shift or 40 hour work week.

Loading...

Loading...