3 - 18

C1

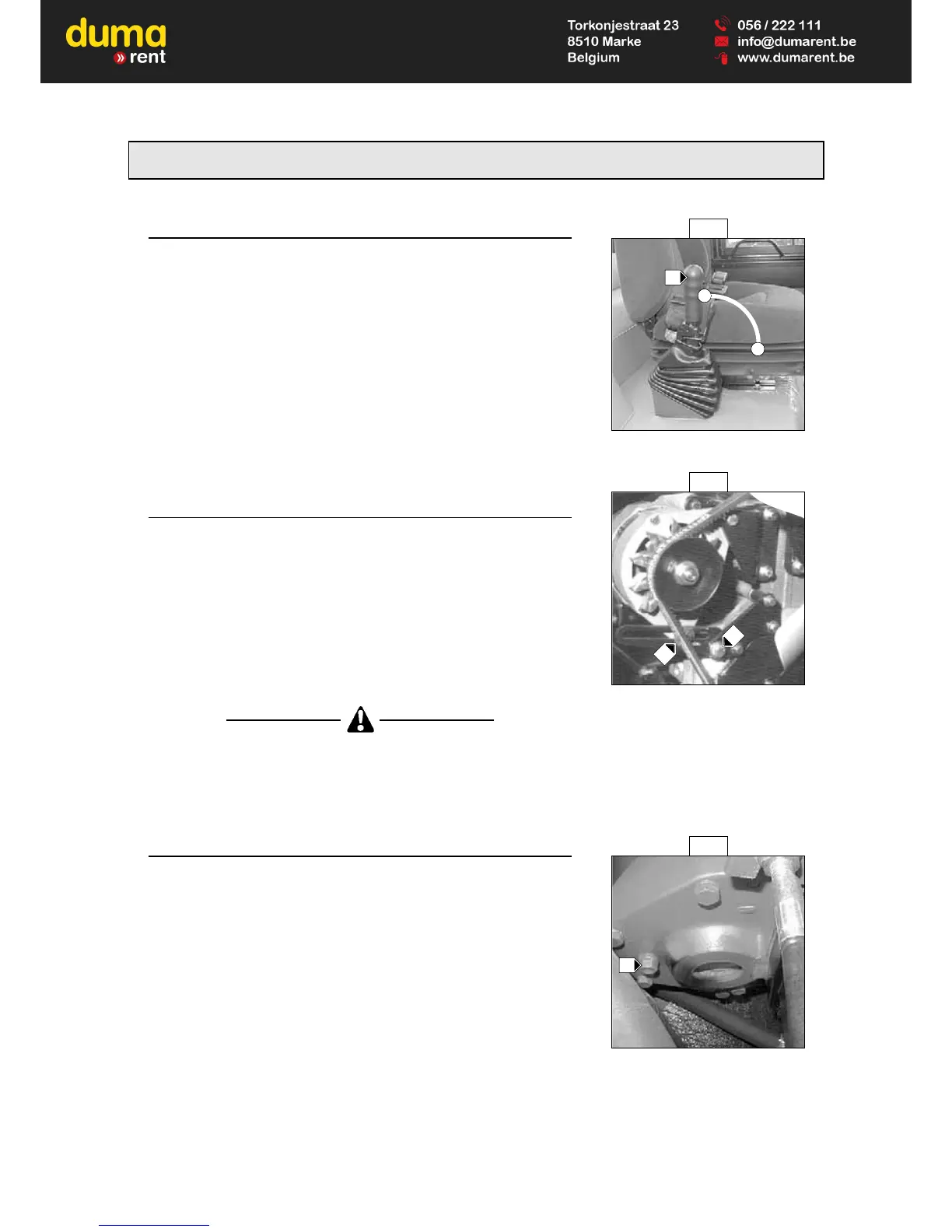

C1 - CHECK AND ADJUST THE PARKING BRAKE

Place the lift truck on level ground.

- Untighten the parking brake in position B (Fig. C1).

- Remove rubber handle 1 (Fig. C1).

- Check the tightening adjustment by locking the parking brake in position A

(Fig. C1).

- The adjustment is correct when the lift truck is held stationary with the

nominal load, on a slope with a gradient of at least 15 %.

- Repeat the operation until the correct braking adjustment is obtained.

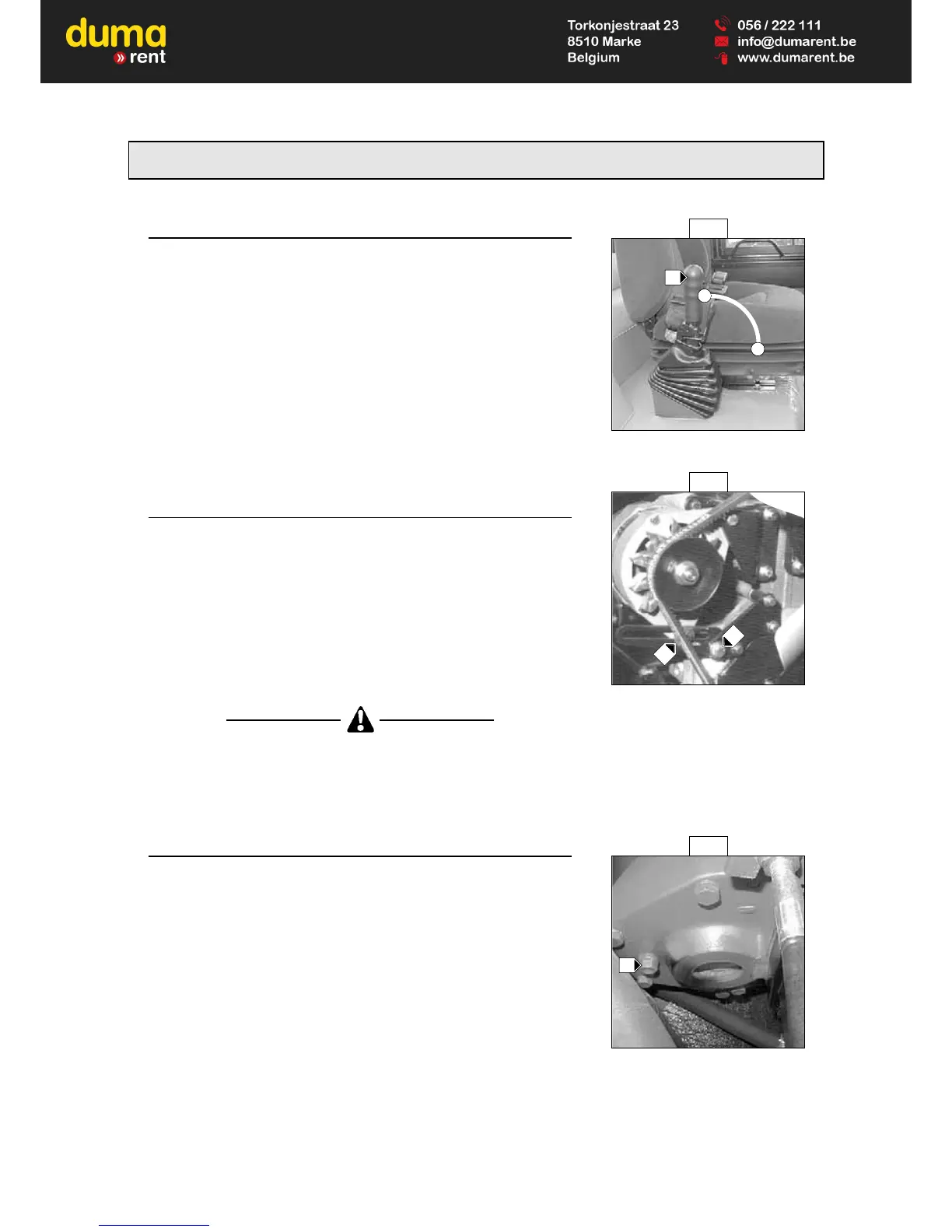

C2 - CHECK AND ADJUST THE TENSION OF THE BELT

ALTERNATOR / FAN / CRANKSHAFT

- Lift up the overhead guard or the cabin (See chapter : INSTRUMENTS AND

CONTROLS in paragraph : 2 - DESCRIPTION).

- Check the belt for wear and cracks and change it if necessary.

- Check the tension of the belt between the fan and alternator pulleys.

- Under a normal pressure exerted with the thumb, the tension should be

approximately 10 mm.

- Carry out adjustments if necessary.

- Untighten screws 1 (Fig. C2) by two to three thread turns.

- Swivel the alternator assembly so as to obtain the belt tension required.

- Retighten screws 1 (Fig. C2).

If the alternator belt has to be changed, check the tension again after the

first 20 hours of operation.

C3 - CHECK THE LEVEL OF THE TRANSFER BOX OIL

Place the lift truck on level ground with the engine stopped.

- Lift up the cabin (See chapter : INSTRUMENTS AND CONTROLS in

paragraph : 2 - DESCRIPTION).

- Remove level plug 1 (Fig. C3). The oil should be flush with the edge of the

filler port.

- If necessary, add oil (See chapter : LUBRICANTS AND FUEL in paragraph :

3 - MAINTENANCE) by the same hole.

-

Replace and tighten the level plug 1 (Fig. C3) (Tightening torque 29 to 34 N.m).

C - EVERY 200 WORKING HOURS SERVICE

C2

C3

1

1

1

1

A

B

Loading...

Loading...