3-26

E - EVERY 1000 HOURS OF SERVICE

Carry out the operations described previously as well as the following operations.

E1 - FUEL TANK

CLEAN

While carrying out these operations, do not smoke or work near a flame.

Place the lift truck on level ground with the I.C. engine stopped.

- Inspect the parts susceptible to leaks in the fuel circuit and in the tank.

- In the event of a leak, contact your dealer.

Never try to carry out a weld or any other operation by yourself, this could provoke an explosion or a fire.

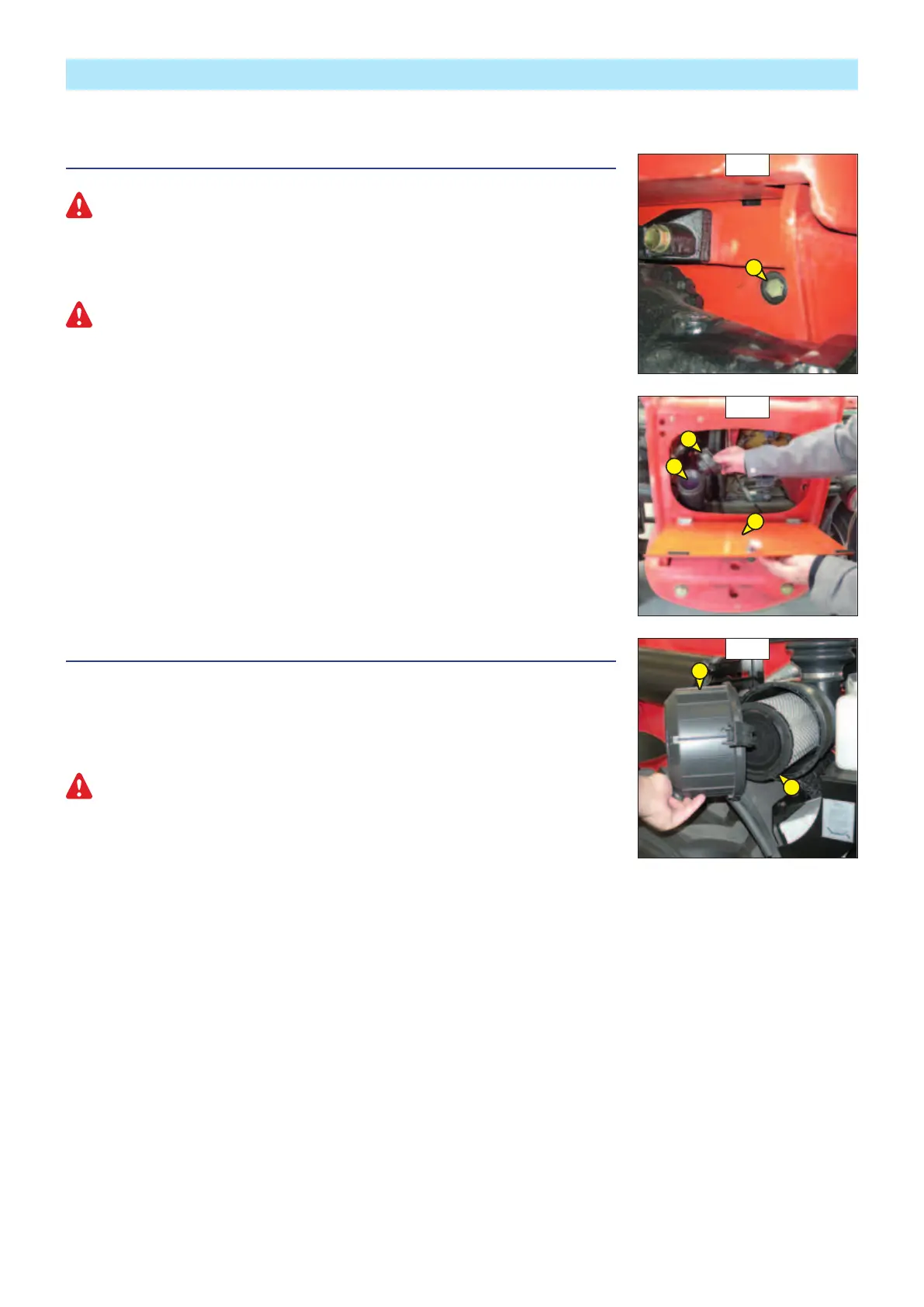

- Place a container under drain plug 1 (fig. E1/1) and unscrew the plug.

- Open access panel 2 (fig. E1/2).

- Remove filler plug 3 (fig. E1/2) in order to ensure that the oil is drained properly.

- Rinse out with ten litres of clean diesel through filler port 4 (fig. E1/2).

- Refit and tighten the drain plug (tightening torque 29 to 39 N.m).

- Fill the fuel tank with clean diesel filtered through the filler port.

- Refit the filler plug.

- Close the access panel.

- If necessary, bleed the fuel circuit (see: 3 - MAINTENANCE: G1 - FUEL SYSTEM).

E2 - DRY AIR FILTER CARTRIDGE

CHANGE

In case of use in a heavily dust laden atmosphere, there are pre-filtration cartridges, see: 3 -

MAINTENANCE: FILTERS CARTRIDGES AND BELTS. Also, the checking and cleaning periodicity

of the cartridge must be reduced (up to 250 hours in a heavily laden dust atmosphere and with

pre-filtration).

Change the cartridge in a clean location, with the I.C. engine stopped. Never operate the lift truck with the air

filter removed or damaged.

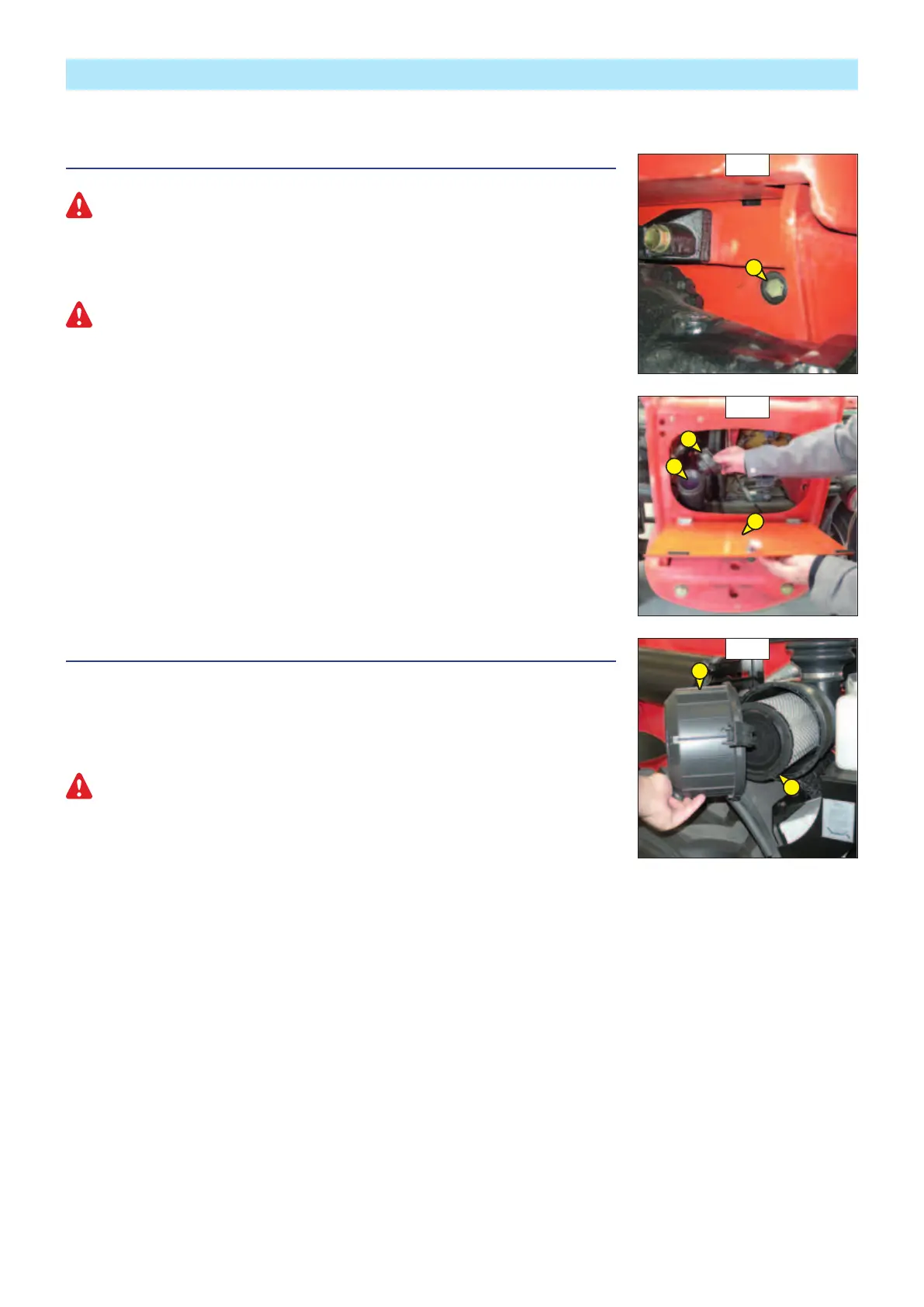

- Open the I.C. engine bonnet.

- Loosen the bolts and remove cover 1 (fig. E2).

- Gently remove the cartridge 2 (fig. E2), taking care to avoid spilling the dust.

- Leave the safety cartridge in place.

- The following parts must be cleaned with a damp, clean lint-free cloth.

• The inside of the filter and cover.

• The inside of the filter inlet hose.

• The gasket surfaces in the filter and in the cover.

- Check pipes and connections between the air filter and the I.C. engine and the connection and state of the clogging indicator on the filter.

- Before mounting check the condition of the new cartridge (see: 3 - MAINTENANCE: FILTERS CARTRIDGES AND BELTS).

- Introduce the cartridge into the filter axis and push it in, pressing the edges and not the middle.

- Reassemble the cover, guiding the valve downwards.

E1/2

4

2

3

E1/1

1

E2

1

2

647421 (22/08/2017)

MT-X 625 Série 2-E3 + COMFORT

Loading...

Loading...