HYDRAULIC SYSTEM RT765E-2 SERVICE MANUAL

2-20

Published 9-04-2014, Control # 422-08

5. Place your hand on the pump to check for excessive

heat buildup caused by binding or other problems. If the

pump is too hot to keep a hand on, stop the engine.

Each section should feel about the same warmth, but

pressure drops in each pump section’s circuit would

explain some difference between sections.

6. Listen for abnormal noises indicating low hydraulic oil

level or internal pump problems. If the pump is making

excessive noise, it is probably sucking air into its inlet,

keeping it from priming. In case of abnormal noise, stop

engine, and inspect the pump and the suction line for a

loose connection, a leak or a damaged or missing o-ring.

7. If the pump seems to be running properly, increase the

rpm to 1500 to 1800 rpm for one to two minutes while

operating no hydraulic functions. Repeat checks in steps

4, 5, and 6.

8. Increase engine speed in steps to full RPM. Repeat

checks in steps 4, 5, and 6.

9. Cycle the components the pump sections power to verify

the pump sections drive them properly. Verify there is no

leaking.

10. Check pressure settings. Refer to Pressure Setting

Procedures, page 2-23.

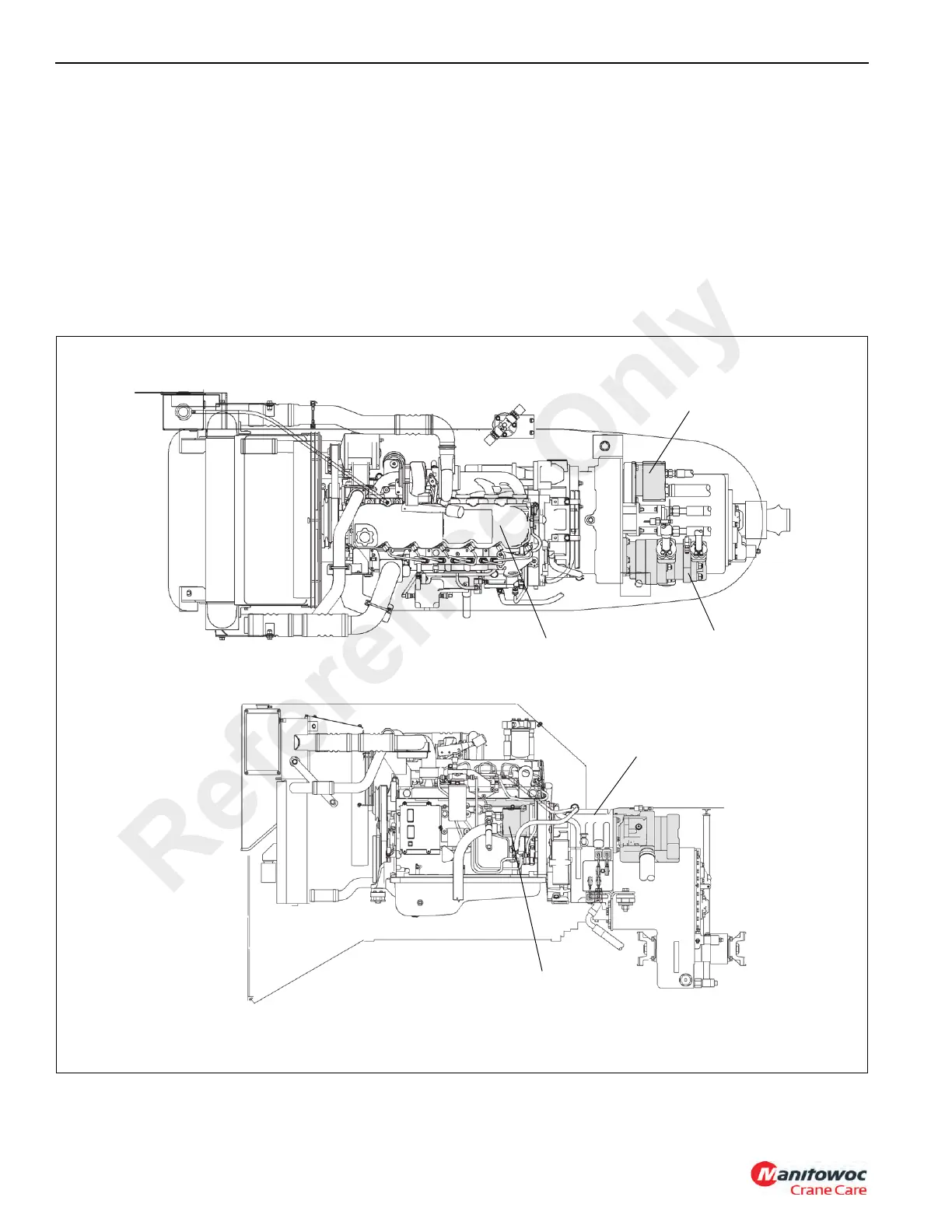

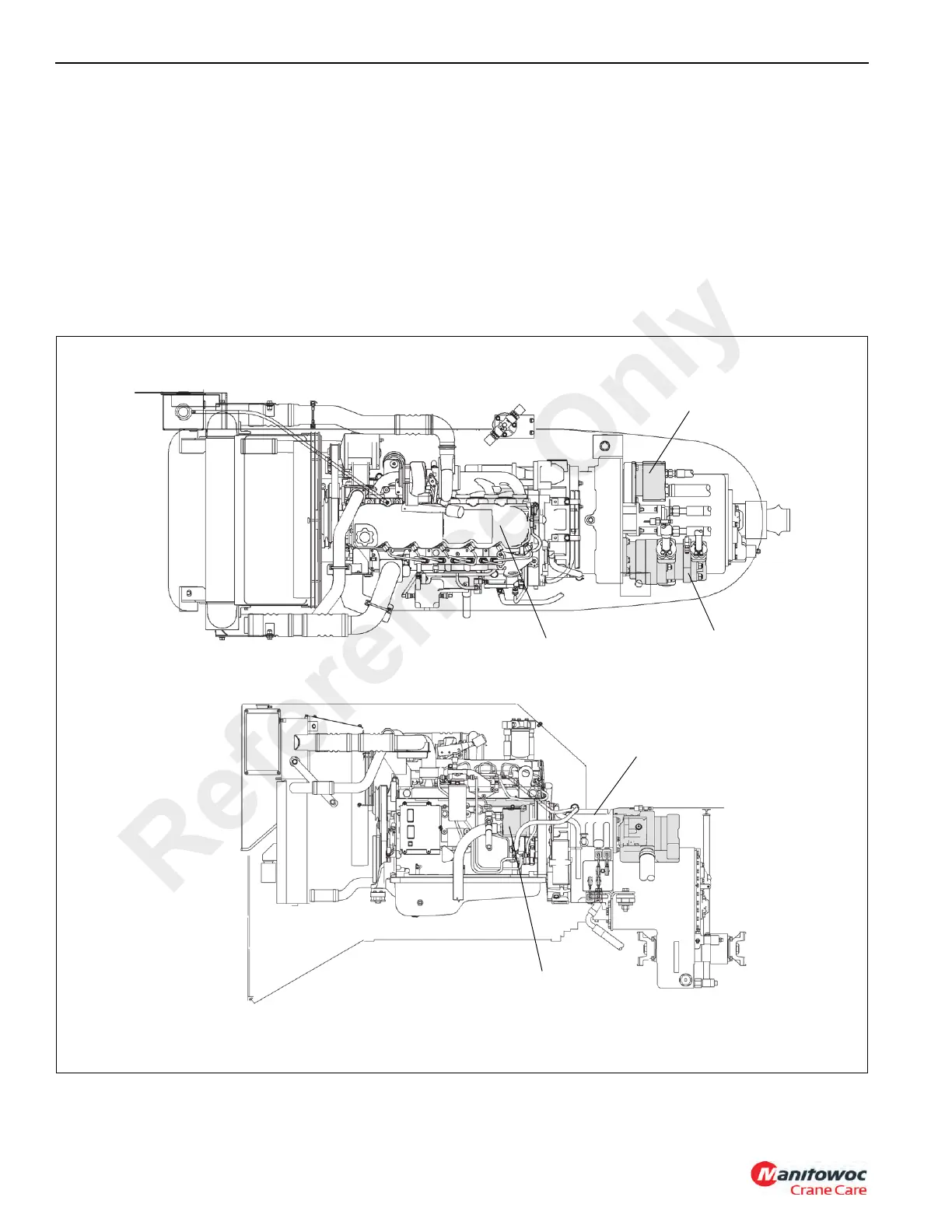

FIGURE 2-4

1

2

4

5

3

6927-3

6927-4

Reference Only

Loading...

Loading...