7-27

RT770E POWER TRAIN

Published 11/26/2014, Control # 447-05

Removal

1. Extend and set the outriggers just enough to take up the

slack in the outrigger pads. Chock the wheels.

2. Position the boom over the side and stop the engine.

3. Remove the engine and transmission/torque converter

from the crane as an assembly. Refer to Engine

Removal, page 7-2.

4. Remove the two-section and single section hydraulic

pumps from the transmission/torque converter. Cover all

openings. Refer to in Hydraulic Pumps, page 2-17 for

removal of the pump.

NOTE: The transmission/torque converter weighs

approximately 438 kg (966 lb) dry.

5. Attach an adequate lifting device to the transmission/

torque converter and take up any slack.

6. Remove the capscrews and hardened flat washers

securing the drive plate assembly to the flywheel.

7. Remove the nuts and washers securing the

transmission/torque converter housing to the engine

flywheel housing.

Installation

NOTE: The transmission/torque converter assembly

weighs approximately 438 kg (966 lb) dry.

1. If a new transmission/torque converter is to be installed,

remove all fittings and brackets from the old one and

install them in the same locations on the new

transmission/torque converter.

2. Install the two-section and single section hydraulic

pumps on the transmission/torque converter. Refer to

Hydraulic Pumps, page 2-17 for installation of the

hydraulic pump.

3. Position the transmission/torque converter to the engine

with the lifting device.

4. Remove all burrs from the flywheel mounting face and

nose pilot bore. Clean the drive plate surface with

solvent.

NOTE: Refer to Figure 7-12.

5. Check the engine flywheel and housing for conformance

to standard S.A.E. No. 3/S.A.E. J-927 tolerance

specifications for bore size, pilot bore runout and

mounting face flatness. Measure and record engine

crankshaft end play.

6. Install the 12 studs in the engine flywheel housing.

Rotate the engine flywheel to align a drive plate

mounting screw hole with the flywheel housing front

access hole.

7. Install a 101.6 mm (4.00 in) long drive plate locating stud

3/8-24 UNF in a drive plate nut.

8. Rotate the transmission/torque converter to align the

locating stud in the drive plate with the flywheel drive

plate mounting screw hole positioned in step 6. Locate

the transmission on the flywheel housing, aligning the

drive plate to the flywheel and the transmission on the

flywheel housing mounting studs. Install the

transmission to flywheel housing nuts and washers.

Tighten the nuts to 41 Nm (30 lb-ft).

9. Remove the drive plate locating stud. Install one drive

plate attaching capscrew and lockwasher. Snug the

capscrew but do not tighten.

NOTE: Some engine flywheel housings have a hole

located on the flywheel housing circumference in

line with the drive plate screw access hole. A

screwdriver or pry bar used to hold the drive plate

against the flywheel will facilitate installation of the

drive plate capscrews.

10. Rotate the engine flywheel and install the remaining

seven flywheel to drive plate attaching capscrews and

hardened flat washers. Snug the capscrews but do not

tighten. After all eight capscrews and hardened flat

washers have been installed, torque the capscrews to

38 Nm (28 lb-ft). This will require torquing each

capscrew, then rotating the engine flywheel until all

capscrews have been torqued.

11. Measure the engine crankshaft end play after the

transmission/torque converter has been completely

installed on the engine flywheel. This value must be

within 0.025 mm (0.001 in) of the end play recorded in

step 5.

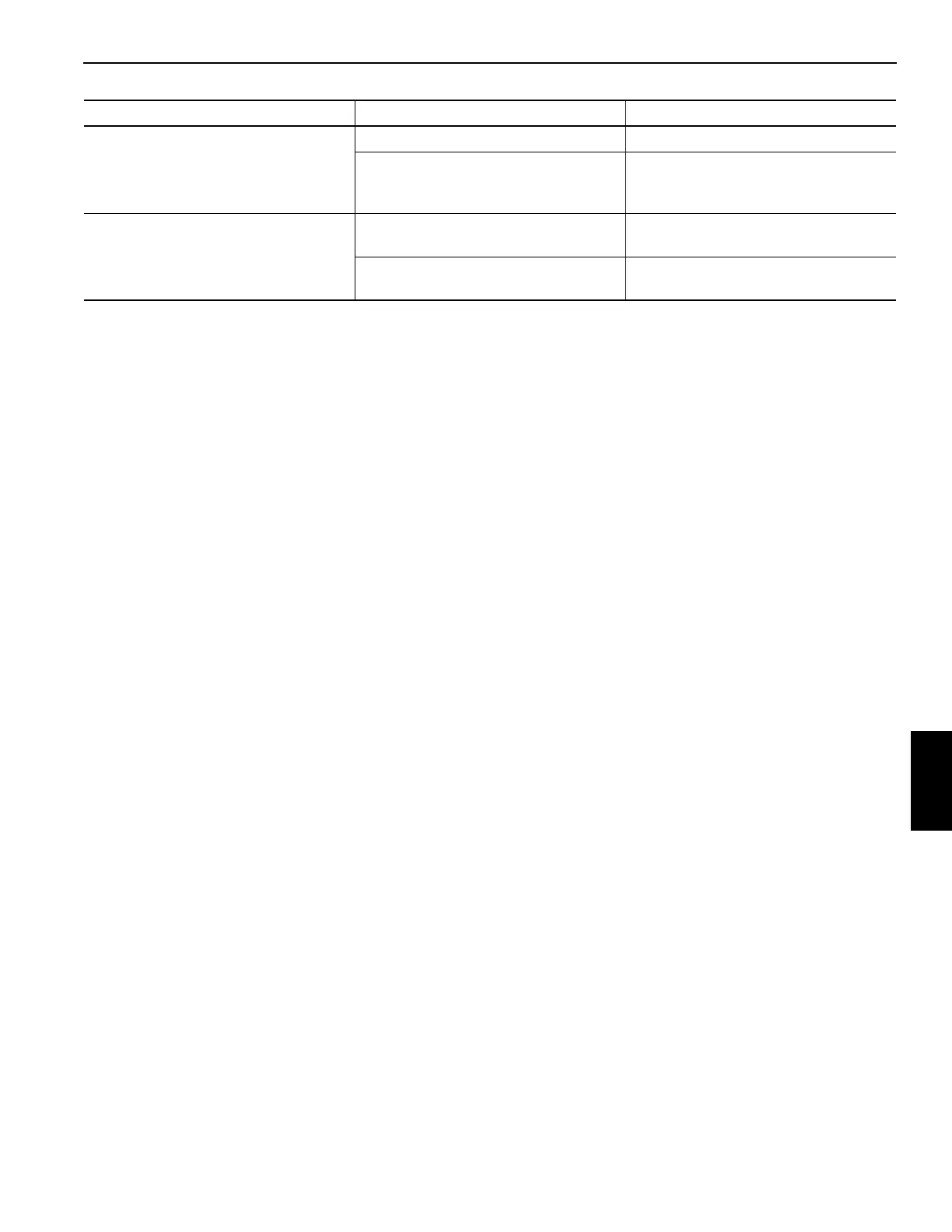

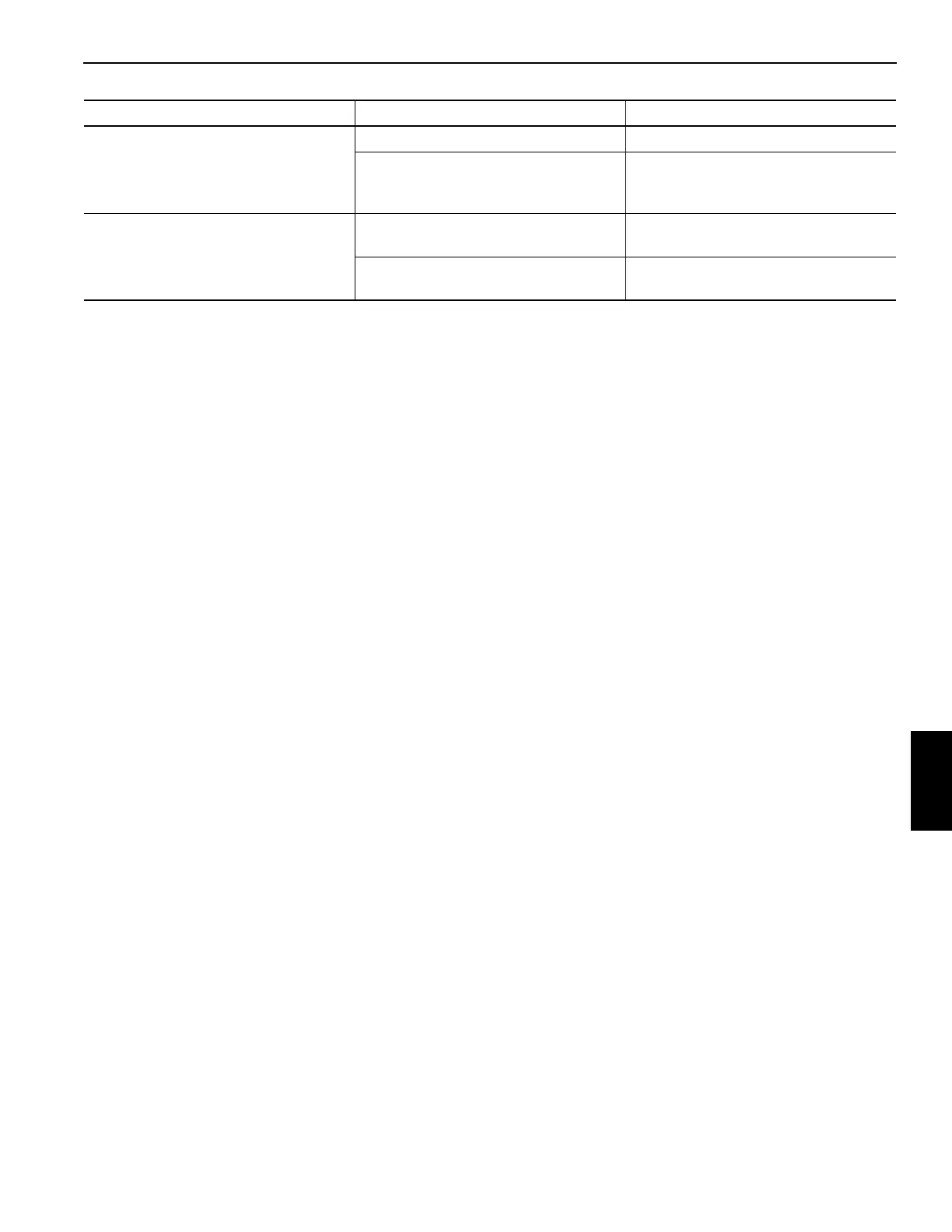

4. Noisy converter. a. Worn oil pump. a. Replace pump.

b. Worn or damaged bearings. b. A complete disassembly will be

necessary to determine what

bearing is faulty.

5. Lack of power. a. Low engine RPM at converter

stall.

a. Tune engine and check

governor.

b. See “Overheating” and make

same checks.

b. Make corrections as explained

in “Overheating.”

SYMPTOM PROBABLE CAUSE REMEDY

Loading...

Loading...