INTRODUCTION RT770E SERVICE MANUAL

1-14

Published 11/26/2014, Control # 447-05

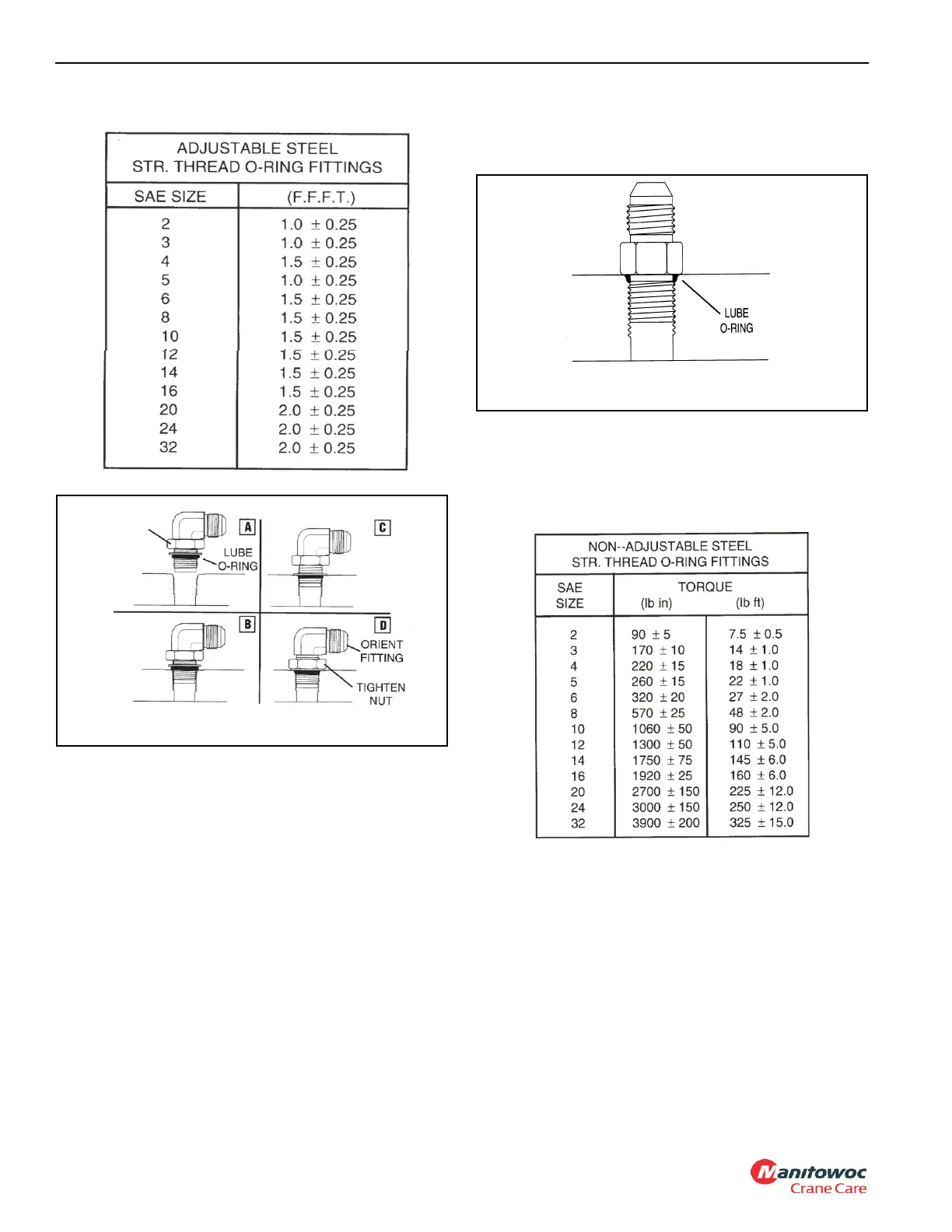

Table 1-4: Adjustable Straight Thread O-ring Fittings

1. Inspect both mating parts for burrs, nicks, scratches, or

foreign particles.

2. Lubricate O-ring with a light coat of clean oil.

3. Back off locknut as far as possible (A).

4. Screw the fitting into port by hand until the backup

washer contacts the face of the port and is pushed all the

way towards the locknut (C).

5. To orientate the fitting, unscrew the fitting the required

amount, but not more than one full turn.

6. Hold the fitting in the desired position and tighten the nut

(D) following the F.F.F.T. method starting with step 4.

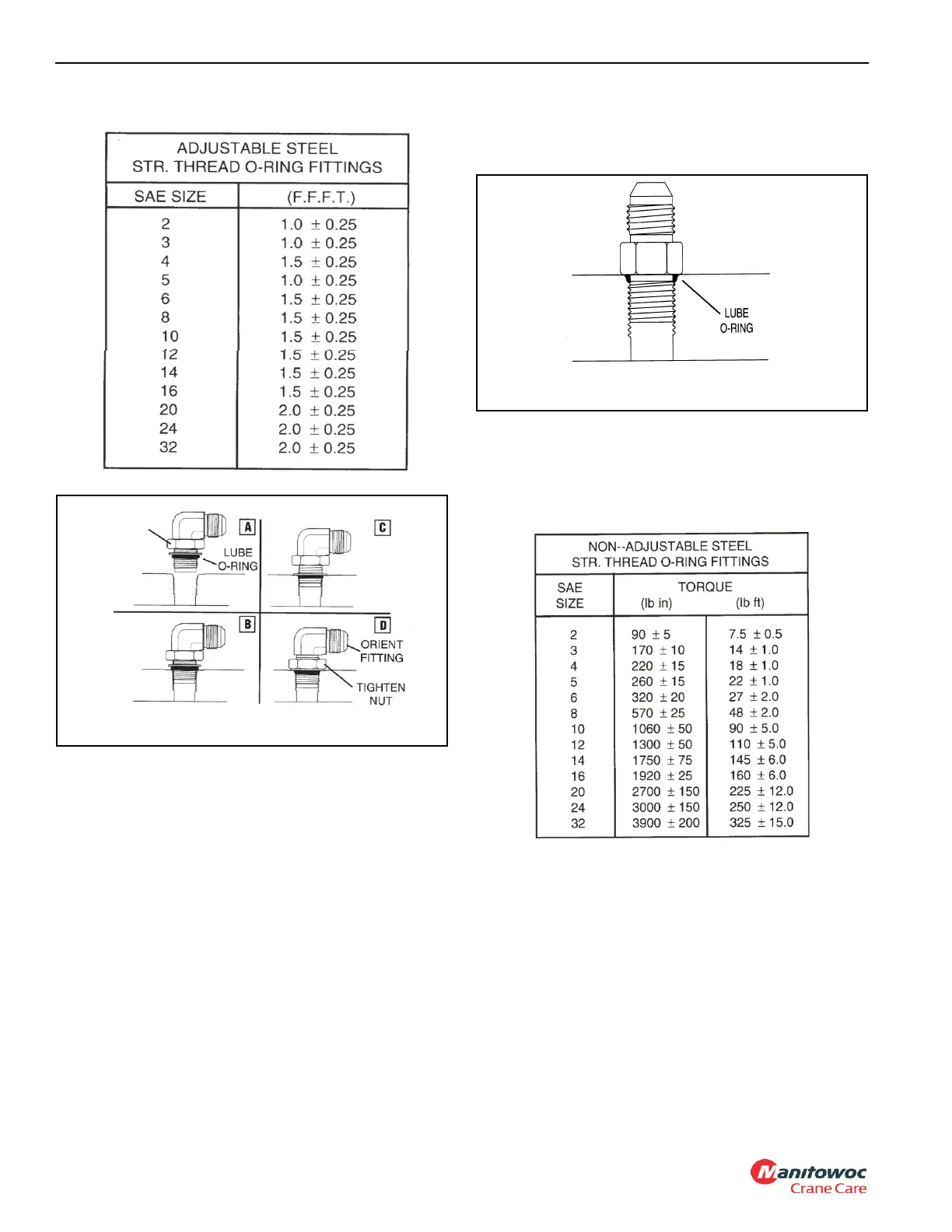

Nonadjustable Straight Thread O-ring Fitting: Fitting

to Port

Refer to (Table 1-5) for the following procedure.

1. Make sure both threads and sealing surfaces are free of

burrs, nicks, scratches or any foreign particles.

2. Lubricate O-ring with clean oil (Figure 1-6).

3. Turn fitting until finger tight.

4. Using the assembly torque method, tighten to given

torque for size from Table 1-5.

Table 1-5: Straight Thread Fittings

Electrical System

Harnesses, Wires, and Connectors

Visually inspect all electrical harnesses, cables, and

connectors every month or 250 hours for the following:

• Damaged, cut, blistered, or cracked insulation.

• Exposed bare wires.

• Kinked or crushed wires and cables.

• Cracked or corroded connectors, battery terminals, and

ground connections.

FIGURE 1-5

Adjustable Fitting to Port

a0030

BACK OFF

NUT

FIGURE 1-6

Non-Adjustable Fitting to Port

a0032

Loading...

Loading...